Dwyer DPW User Manual

Page 16

4.12.4 - Submenu DAC_A Flow Output

This menu selection provides current value of the DAC register for analog flow

output circuitry.

4.12.5 - Submenu DAC_B Temperature Output

This menu selection provides current value of the DAC register for analog

temperature output circuitry.

4.12.6 - Submenu CPU Temperature

This menu selection provides current value of the PCB and CPU temperature in °C.

4.12.7 - Submenu Raw VCC Reading

This menu selection provides current normalized value of the DC/DC converter

output in counts. The typical values are in the range between 2800 and 3200

counts.

5. Analog Output Signals

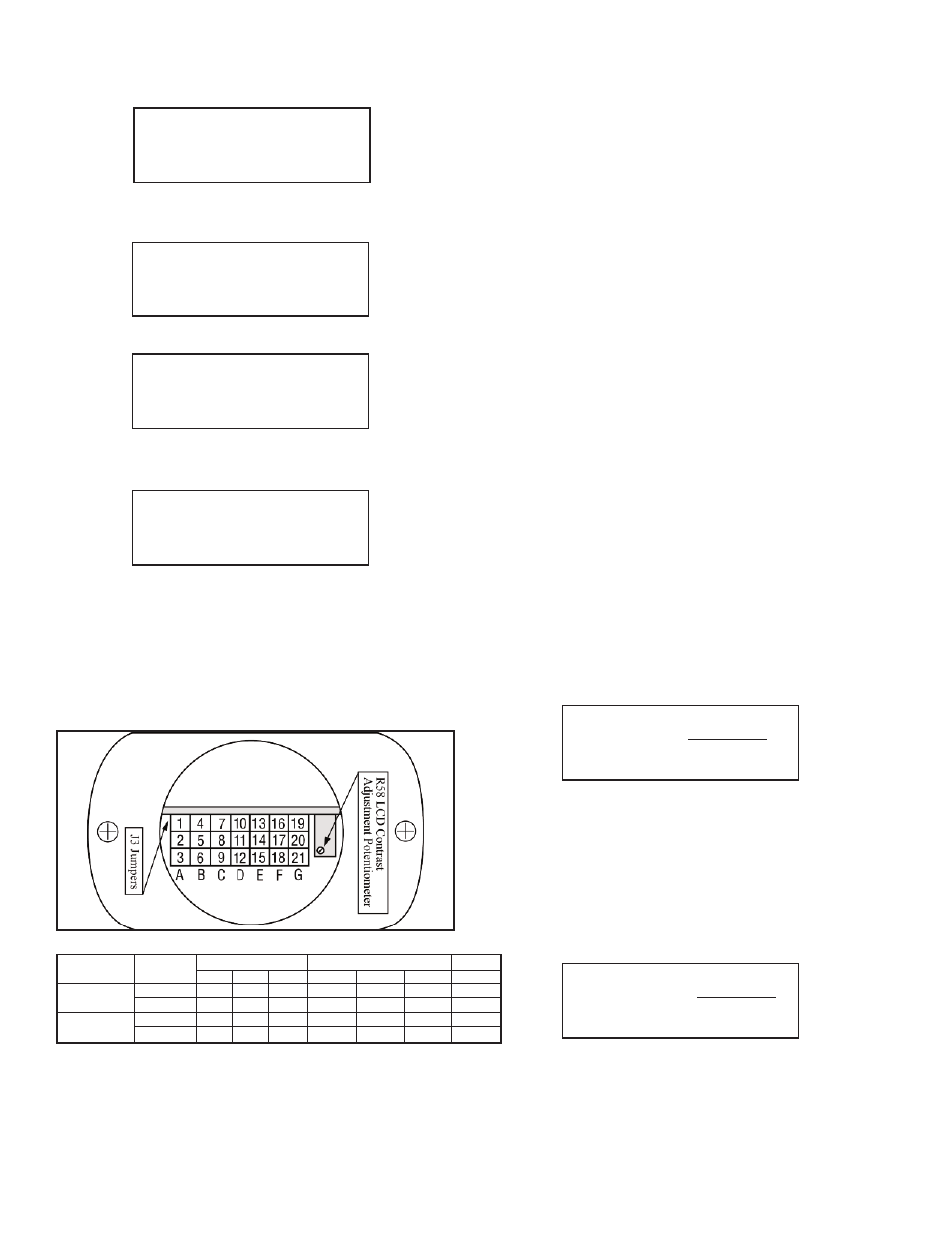

5.1 - Analog Output Signals Configuration

DPW series Flow Meters are equipped with calibrated 0 to 5 Vdc and/or 4 to 20 mA

output signals for flow and temperature* process variables. The set of the jumpers

(J3A, J3B, J3C, J3D, J3E, J3F) located on the top of the flow meter, inside of the

maintenance access window (see Figure 5-1 “DPW configuration jumpers”) are

used to switch between 0 to 5 Vdc or 4 to 20 mA output signals. Jumpers J3A, J3B,

J3C are used to set flow analog output type and jumpers J3D, J3E, J3F are used

to set temperature* analog output type (see Table 5-1). Jumper J3G is used to

configure RS-485 termination resistor (by default is off).

5.2 - Analog Output Signals calibration

Note: The analog output available on the DPW Flow Meter was calibrated at the

factory for the specified fluid and full scale flow range (see the device’s front label).

There is no need to perform analog output calibration unless the EEPROM IC was

replaced or offset/span adjustment is needed. Any alteration of the analog output

scaling variables in the EEPROM table will VOID calibration warranty supplied with

instrument.

Note: It is recommended to use the Dwyer Instruments, Inc. supplied calibration

and maintenance software for analog output calibration. This software includes an

automated calibration procedure which may radically simplify calculation of the

offsets and spans variables and, the reading and writing for the EEPROM table.

The DPW analog output calibration involves calculation and storing of the offset

and span variables in the EEPROM for each available output. The 0 to 5 Vdc output

has only scale variable and 20 mA output has offset and scale variables. The

following is a list of the EEPROM variables used for analog output computation:

Analog Flow Output variables

Index Name

Description

39

FoutScaleV

- DAC 0 to 5 Vdc Flow Analog Output Scale

41

FoutScale_mA

- DAC 4 to 20mA Flow Analog Output Scale

42

FoutOffset_mA

- DAC 4 to 20mA Flow Analog Output Offset

Analog Temperature Output variables*

Index Name

Description

43

ToutScaleV

- DAC 0 to 5 Vdc Temperature Analog Output Scale

45

ToutScale_mA

- DAC 4 to 20mA Temperature Analog Output Scale

46

ToutOffset_mA - DAC 4 to 20mA Temperature Analog Output Offset

5.2.1 - Initial Setup

Power up the DPW Flow Meter for at least 15 minutes prior to commencing the

calibration procedure. Make sure absolutely no flow takes place through the meter.

Establish digital RS-485/RS-232 communication between PC (communication

terminal) and DPW. The commands provided below assume that calibration will be

performed manually (w/o Dwyer

®

supplied calibration and maintenance software)

and the device has RS-485 address 11. If Dwyer

®

supplied calibration and

maintenance software is used, skip the next section and follow the software

prompts.

Enter Backdoor mode by typing: !11,MW,1000,1[CR]

Unit will respond with: !11,BackDoorEnabled: Y

Disable DAC update by typing: !11,WRITE,4,Y[CR]

Unit will respond with: !11,DisableUpdate: Y

5.2.2 - Flow 0 to 5 VDC analog output calibration

1. Install jumpers J3A, J3B and J3C on the PC board for 0 to 5 Vdc output

(see Table 5-1).

2. Connect a certified high sensitivity multi meter set for the voltage measurement

to the pins M (+) and K (-) of the DPW 12 Pin "M16" connector.

3. Write 4000 counts to the DAC_A channel: !11,WRITE,0,4000[CR]

4. Read voltage with the meter and calculate FOutScaleV value:

5. Save FOutScaleV in to the EEPROM: !11,MW,39,X[CR]

Where: X – the calculated FoutScaleV value.

5.2.3 Flow 4 to 20 mA analog output calibration

1.

Install jumpers J3A, J3B and J3C on the PC board for 4-20 mA output

output (see Table 5-1).

2.

Connect a certified high sensitivity multimeter set for the current

measurement to pins M (+) and K (-) of the DPW 12 Pin "M16" connector.

3.

Write 4000 counts to the DAC_A channel: !11,WRITE,0,4000[CR]

4.

Read current with the meter and calculate FoutScale_mA value:

5.

Write zero counts to the DAC_A channel: !11,WRITE,0,0CR]

6.

Read offset current with the meter and calculate FoutOffset_mA value:

7.

Save FoutScale_mA in to the EEPROM: !11,MW,41,Y[CR]

Save FoutOffset_mA in to the EEPROM: !11,MW,42,Z[CR]

Where: Y – the calculated FoutScale_mA value.

Z – the calculated FoutOffset_mA value.

DAC_A Output (F)

3125 Counts

DAC_B Output (T)

1358 Counts

CPU Temperature

35.8 C

Raw VCC Reading

3065 Counts

Figure 5-1 DPW Configuration Jumpers

Analog

Output

RS-485 220 Ω

Termination

Resistor

Function

0 to 5 VDC

4 to 20 mA

OFF

ON

J3A

2 to 3

1 to 2

J3B

5 to 6

4 to 5

J3C

8 to 9

7 to 8

J3D

11 to 12

10 to 11

J3E

14 to 15

13 to 14

J3F

17 to 18

16 to 17

J3G

20 to 21

19 to 20

Analog Flow Output

Analog Temp. Output*

RS-485

FoutScaleV=

20000

Reading[V]

FoutScale_mA =

4000

Reading[mA]

Page 16