Badger Meter SRD/SRI Valve Positioners User Manual

Page 58

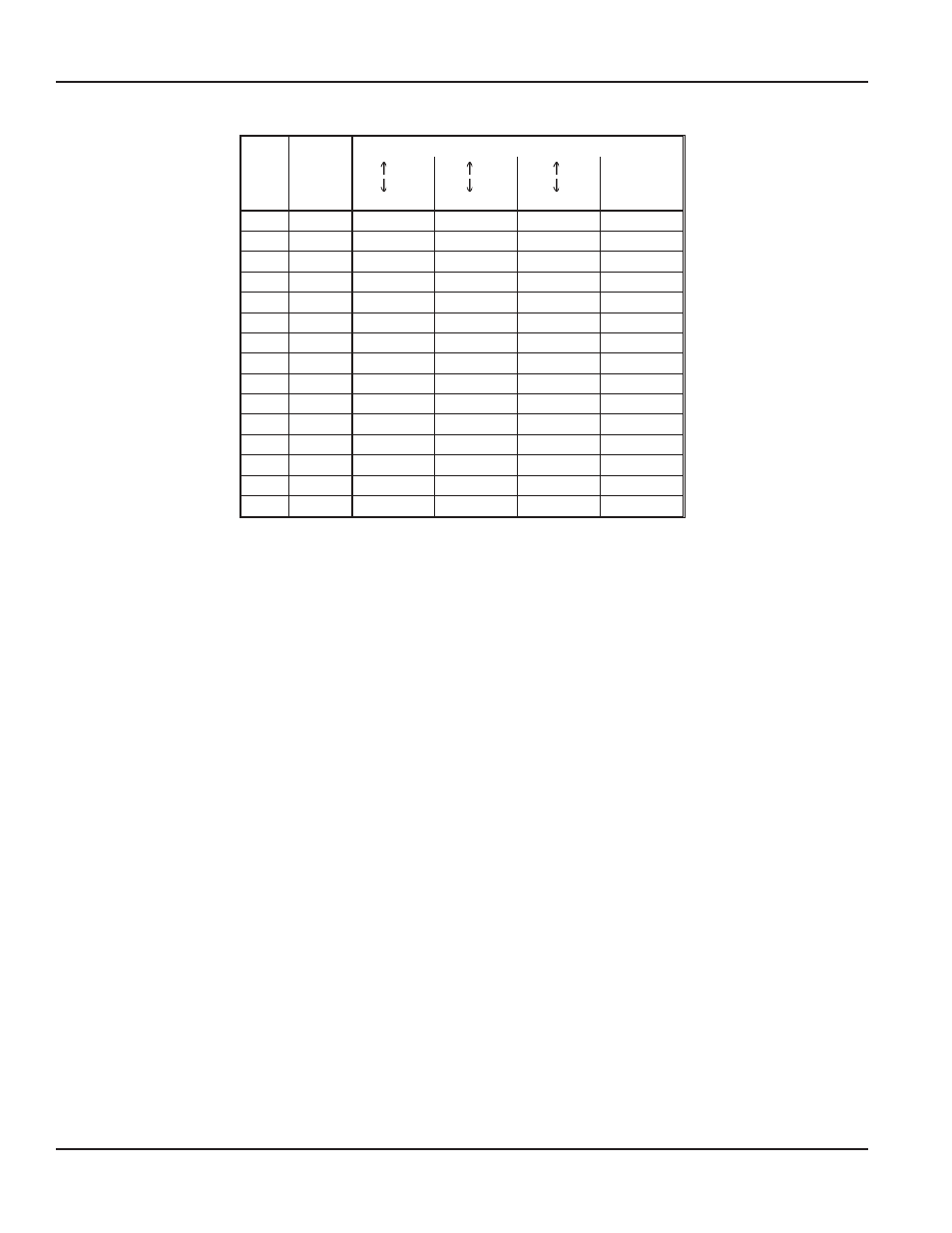

Table 4: Allocation of the parameter values to coding:

In LCD shown values:

[in Menu Nr.]

Code

LEDs

1 2 3 4

P

[6.2]

P

[6.1]

Tn

[6.4]

Tn

[6.3]

(sec)

T63

[6.6]

T63

[6.5]

(sec)

Dead band

[6.7]

(%)

1

1 0 0 0

2

1

0.1

0

2

0 1 0 0

2.66

1.33

0.15

0.12

3

1 1 0 0

3.50

1.75

0.25

0.16

4

0 0 1 0

4.7

2.4

0.35

0.22

5

1 0 1 0

6.3

3.2

0.5

0.3

6

0 1 1 0

8.4

4.2

0.75

0.4

7

1 1 1 0

11.2

5.6

1.15

0.53

8

0 0 0 1

15

7.5

1.75

0.7

9

1 0 0 1

20

10

2.6

0.94

10

0 1 0 1

26.6

13.3

3.9

1.25

11

1 1 0 1

35.5

17.8

5.9

1.67

12

0 0 1 1

47.3

23.7

8.85

2.22

13

1 0 1 1

63.1

31.6

13.3

2.96

14

0 1 1 1

84.2

42.1

20

3.95

15

1 1 1 1

112.2

- off -

30

5.3

Remarks to Controller Tuning

If AUTOSTART does not find the optimum setting the following may be the result:

A) slow response to setpoint, long positioning time or long neutral time

B) continuous oscillation following setpoint jump

C) wide and high overshoot

For the assessment of the control 12 5 % jumps in both directions may be performed in Menu 8 The valve dynamics may be

observed at LCD or the mechanical indicator

Prior to changing parameters for valve dynamics a number of items are to be checked, see below The pneumatic output can

be operated directly without controller via Menu 7 and the valve movement may be assessed

In case of behavior A) check:

1 Is the Proportionate gain P (Menu 6 1) or P (Menu 6 2) too small?

Remedy: Increase parameters according to chart 4

2 Is the air pressure high enough to possibly overcome the actuator spring force and friction?

Remedy through increasing air pressure

3 Is the actuator volume high, possibly requiring an increased air capacity for fast valve movement?

Remedy: through booster, see accessories, or spool valve option

4 Was AUTOSTART performed in Menu 2 and did messages 8 resp 9 occur (messages, see table)?

Remedy: “AUTOSTART” in Menu 2 resp observe information in table

5 Has the parameter for the positioning time been set at a value too high?

Remedy: decrease both parameters “T63" in Menu 6 5 or 6 6

6 Is valve packing too tight resulting in a very high friction?

7 Is the supply air filter blocked?

8 Has the supply air been contaminated by small oil drops, particulate or are pneumatic parts possibly blocked?

Remedy: exchange pneumatic parts; possibly use a suitable air supply station

Behaviors B) and C) check:

1 Is the air capacity possibly too high, e g through spool valve or booster?

Remedy: Work, if necessary, without booster or use version without spool valve

Operation

Page 58

August 2014

POS-UM-00010-EN-03