Precision air conditioning, Smartcool, Maintenance – Airedale SmartCool 11-233kW User Manual

Page 175

Precision Air Conditioning

SmartCool

TM

– D

Precision Air Conditioning

175

Installation, Maintenance and Commissioning Manual :6877419 02/2013

Maintenance

CAUTION

ALL work MUST be carried out by technically trained competent personnel.

The equipment contains live electrical and moving parts, ISOLATE remotely prior to

maintenance or repair work. Ensure Electrical lock-off procedures are carried out.

IMPORTANT

Ensure relevant F-Gas Regulation checks are carried out at the appropriate period.

General Maintenance

The maintenance schedule indicates the time period between maintenance operations.

Access to the various components is via the doors to the front of the unit.

Service Indicator

A visual indication of the service status of major components is provided for convenience.

Filters

CAUTION

It is good practice to check filters at each maintenance visit.

Unit filter condition is monitored via the microprocessor. The operational time is indicated

along with the operational setpoint. This can be obtained through the maintenance sub

menu of the controller

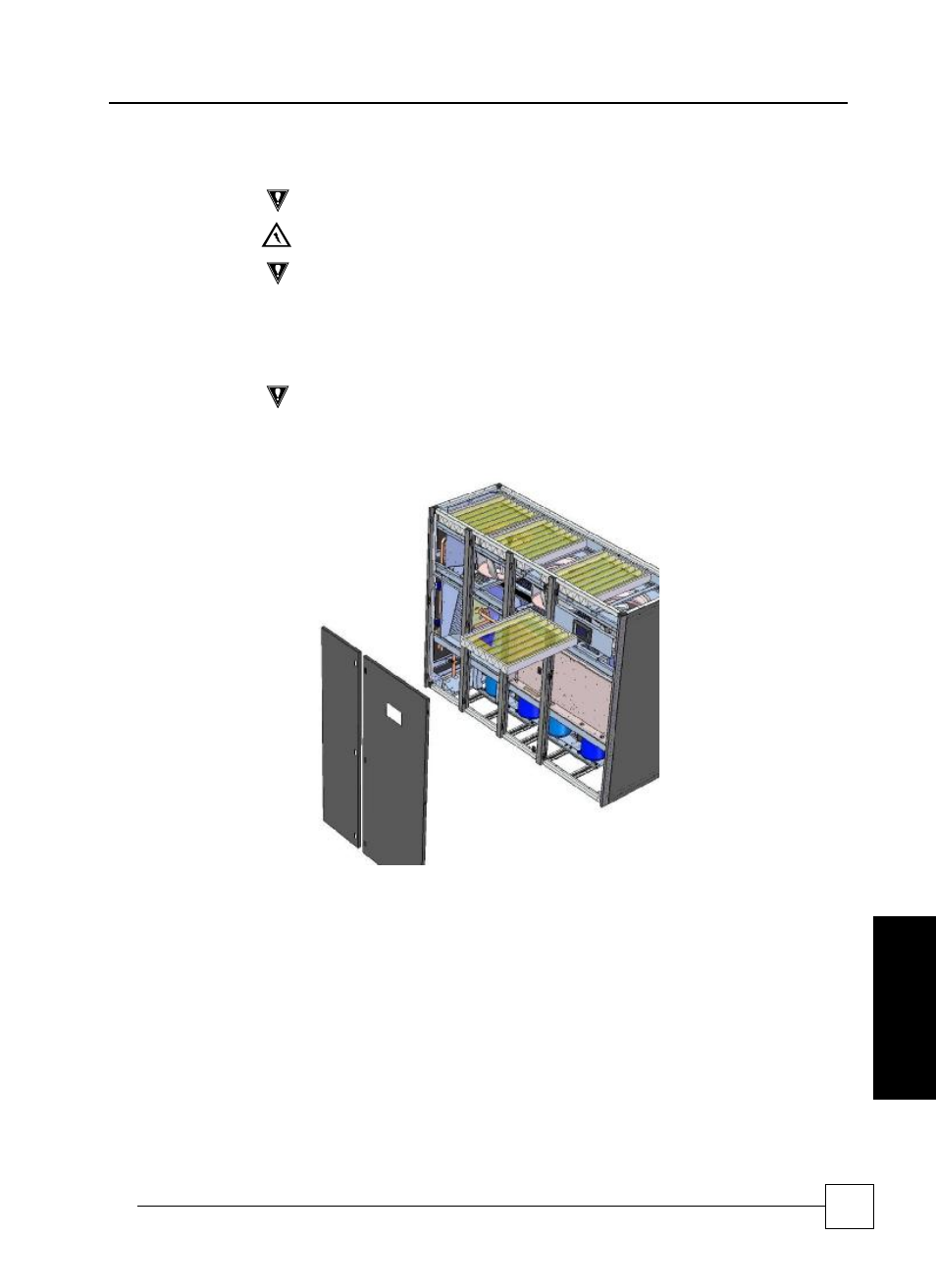

Filter Changing

·

The filters are

changed by sliding

each filter through

the right hand door

of the unit.

Compressors

The compressor oil sight glass (where fitted) should indicate a level of between 1/3

and 2/3 to ensure correct operation.

M

a

in

te

n

a

n

ce