West Control Solutions CALogix User Manual

Page 4

CALogix Installation Instructions

System Overview

CALogix is a modular multi-loop PID controller with logic function capability. The controller consists of a DIN-rail mount

base-unit that incorporates the power supply, RS485 communications ports and slots for up to 4 control modules. The

control modules are available as PID or Logic I/O and can be selected then mounted into the base-unit as required for the

application. Variations in PID control modules include temperature sensor and linear (0-50mV, 4-20mA, 0-5V & 0-10V)

inputs with options for relay, ssd or analog (4-20mA, 0-5V & 0-10V) outputs. Logic I/O modules have user defined 0-5, 0-

10, 0-24Vdc inputs with relay or ssd outputs. All wiring connectors to the base unit and control modules are plug-in to

reduce installation and maintenance times.

CALogix is configured using the Windows

™ based CALogix-sw configuration tool which is provided with each base-unit.

PID setup, input & output parameter settings, profile creation and writing logic function block diagrams can all be

performed within the software utility. These settings can be read, modified and written to and from the controller and also

saved on the PC as a file to be recalled at a later date when required. The program also provides information on current

process value, set-points and output status which can be useful when commissioning the system.

Mechanical Installation

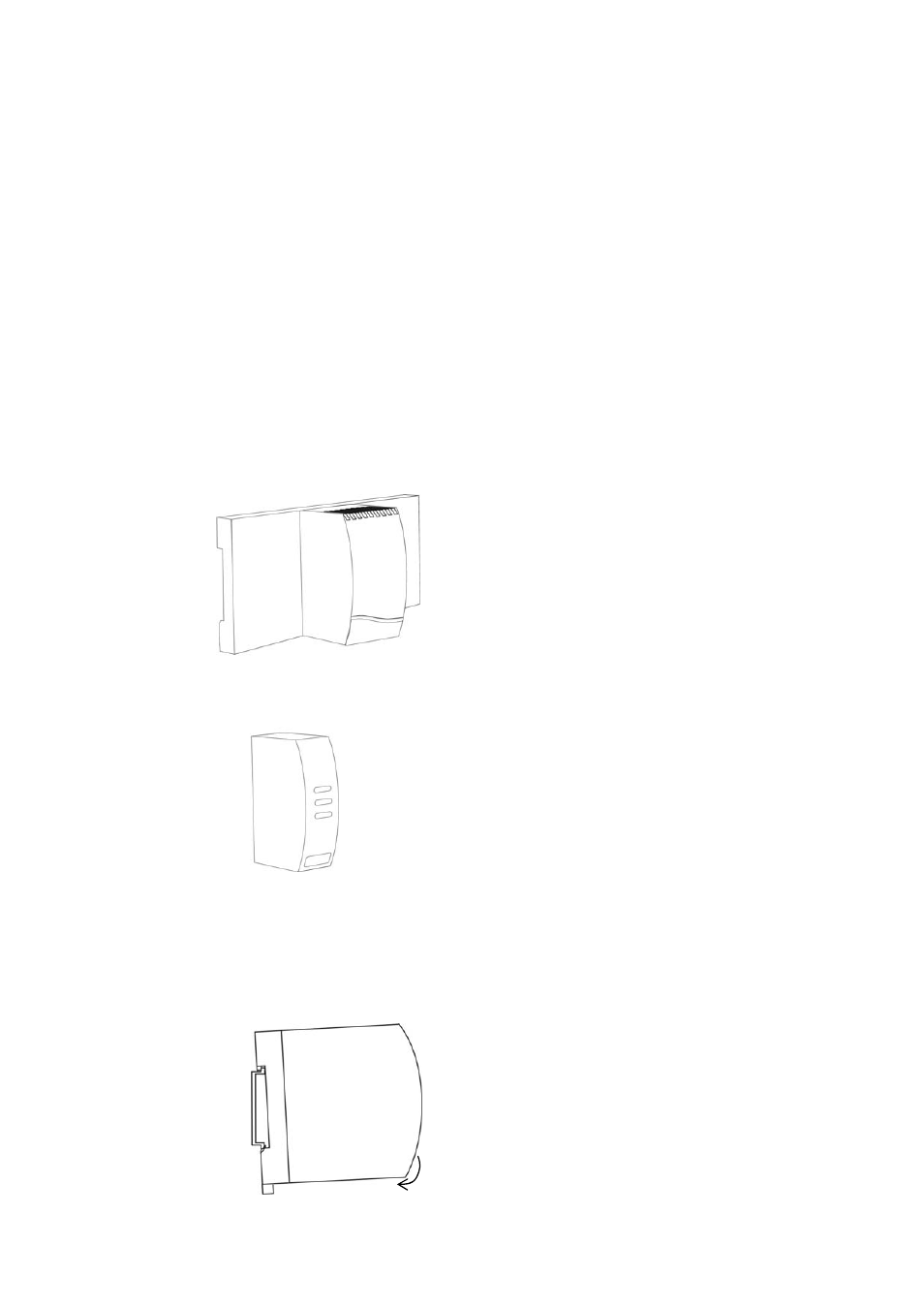

The controller is designed as two main components

BASE-UNIT

DIN rail mount device containing main CPU and connections for up to 4 control modules.

CONTROL MODULE

PID or Logic control modules can be mixed as required for the application and plugged in to base-unit.

1 base-unit and 1-4 control modules must be used for operation of product. A CALogix system can only be configured

using CALogix-sw pc-based software.

MOUNTING

To mount a base unit with control modules proceed as follows:

1.

Affix 35mm type DIN rail securely to mounting surface, minimum length 140mm. The unit should be mounted

vertically as shown.

2.

Attach carrier unit to DIN rail ensuring the spring release is at the bottom, facing downward.

Page 4 of 44