A' 'b – KROHNE BM 90 EN User Manual

Page 23

23

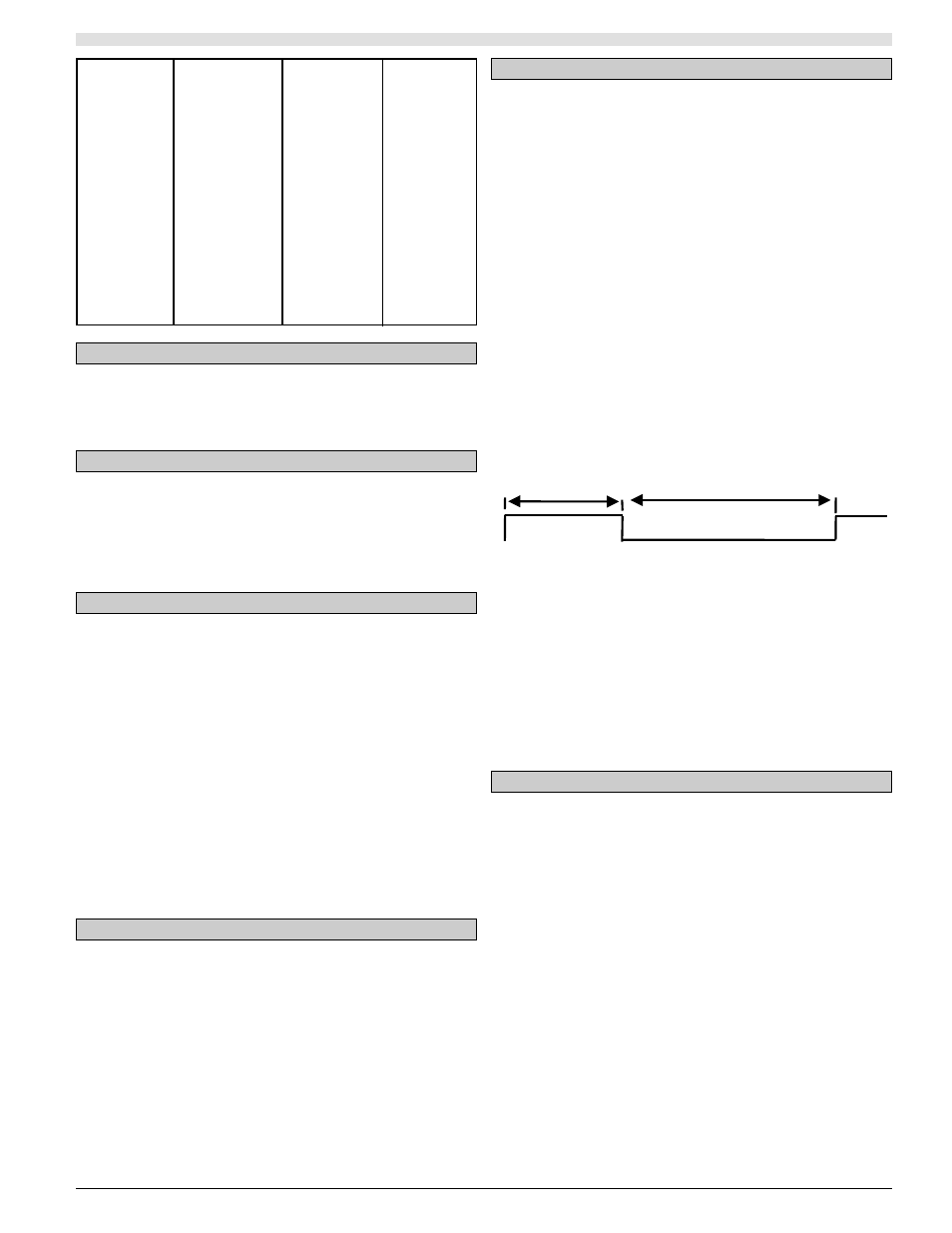

Pr. 46 Maximum Flow Rate (D=0)

Pr. 47 Time Base of Maximum Flow Rate (D=1)

Pr. 48 Totalizer Display Conversion (D=0)

Pr.49

Control External Counter (D=0.00)

Used to totalise on the display in flow units larger than

those entered at Pr.46 (max. flow rate)

Enter

0

Multiples by 1

1

Multiples by 0.1

2

Multiples by 0.01

3

Multiples by 0.001

4

Multiples by 0.0001

5

Multiples by 0.00001

6

Multiples by 0.000001

7

Multiples by 0.0000001

e.g. If Pr.46 is entered as litres, at Pr.48 enter ‘3‘ to total-

ize the flow in cubic meters.

Enter the maximum flow rate in units per second, per

minute, per hour or per day, corresponding to maximum

head, set at Pr.4 and then define the time base at Pr.47.

Enter the value corresponding to the flow rate time base.

Enter 1 =

units per second

2 =

units per minute

3 =

units per hour

4 =

units per day

If Pr.20 is set to 5, "Totaliser Drive", then enter the

amount which each relay trip is to represent in totalised

units. See example 5 on page 39.

e.g.

If "litres" entered at Pr.46 and Pr.48 is ’0’ then to

totalise in cubic metres enter 1000.

If an entry is made at Pr.48 for the internal totaliser then

to use the same unit for an external counter enter ’1’.

After making entries in Pr.49, go to Pr.98 to clear and ini-

tiate totaliser.

Flume K

Factor

Flume K

Factor

Size-Inches

for US GPM

Size-Feet

for US GPM

1

3.22

10

331.60

2

6.45

12

393.70

3

9.46

15

486.90

6

18.20

20

642.10

9

30.80

30

797.40

12

40.90

40

1263.00

18

58.90

50

1574.00

24

76.30

36

110.00

48

142.00

72

204.70

96

256.60

Pr. 50 Penstock Control (D=1)

Enter

1 - No drive

2 - Penstock control

The control system uses relays 1 and 2 to drive a pen-

stock up and down respectively to maintain the flow in a

channel within certain limits.

The designations for relays 1 and 2 are ignored, but the

following values have to be set.

Pr.9

: Top flow limit

) In units defined by

Pr.10

: Bottom flow limit

) Pr.46 entry

Pr.12

: Width of drive pulse (seconds)

Pr.13

: Time between drive pulses (seconds)

See example 4.6 on page 32.

The penstock drive consists of a pulse train of variable

time base which drives the penstock up and down.

'a'

'b'

In order to even out the wear of pumps it is possible to

alternate the sequence in which pumps are used. (Pr.52

must be set to 1).

Enter

1

Sequence by set points (i.e. no alternation)

2

Alternate RL1 and RL2

3

Alternate RL1, RL2 and RL3

4

Alternate RL1, RL2, RL3 and RL4

5

Alternate RL1, RL2, RL3, RL4 and RL5

Pr. 51 Pump Sequencing (D=1)

The time ’a’ is set by Pr.12 and ’b’ is set by Pr.13 in sec-

onds, this allows any shape drive train to be defined.

The control will maintain the flow between two limits, a

high limit set by Pr.9 and a low limit set by Pr.10.

If the flow exceeds the value in Pr.9 relay 2 drives the

penstock down. If the flow is below the value in Pr.10

relay 1 drives the penstock up. See Example 6.