Mechanical installation – KROHNE VFM 3100 EN User Manual

Page 9

9

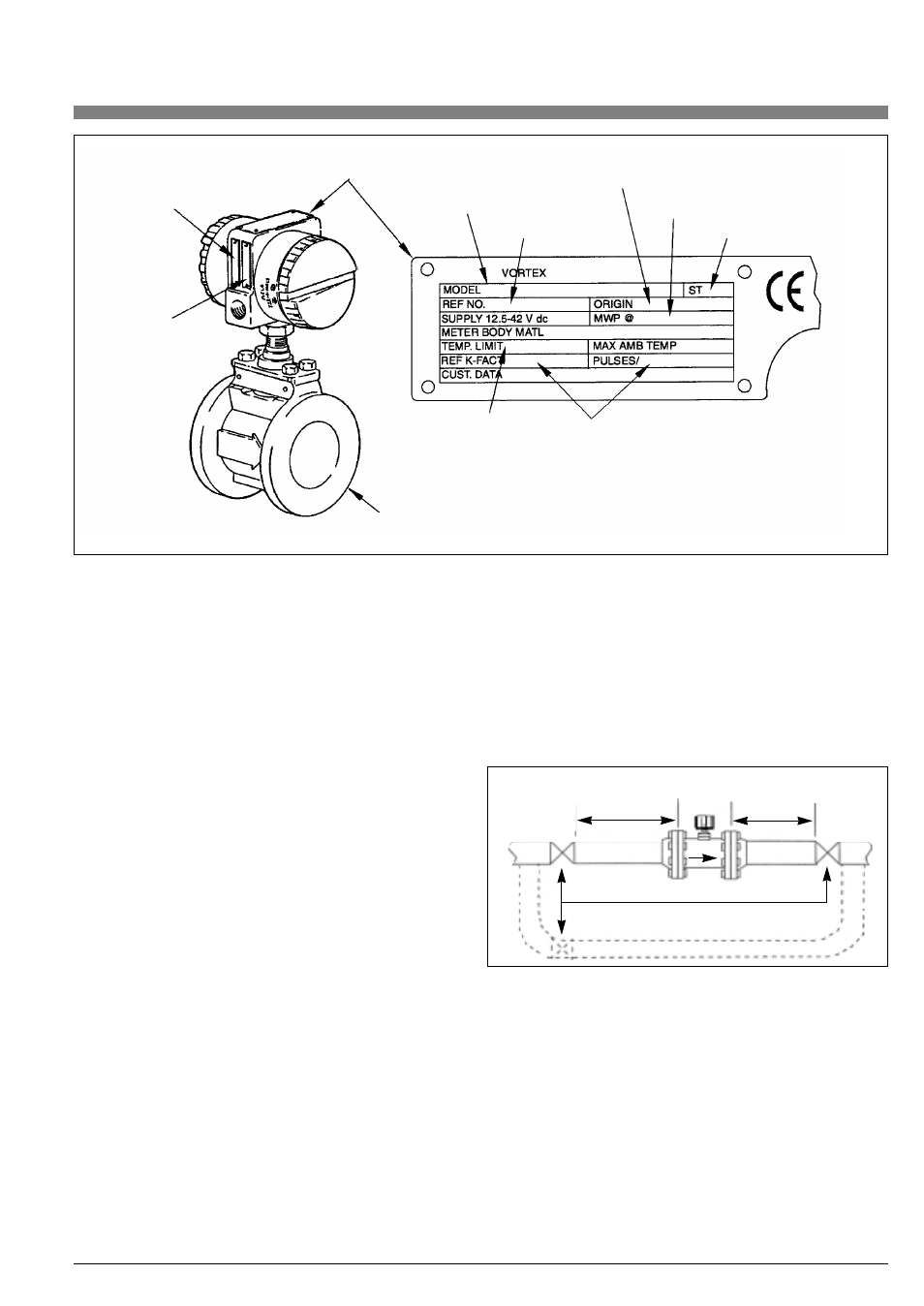

Data Label

Certification Label

Measuring

Range Label

Model Code

Serial No.

Productioncode

Maximum Pressure

Style Letter

Temp Limit per

Sensor Option

Complete VFM 3100

Calibration

Factor

Figure 3. VFM 3100 Identification

1.2. Mechanical Installation

There are two mounting arrangements: integral and remote. The

following sections deal with both the integral and remote VFM 3100

arrangements.

1.2.1. Piping Considerations

Effects of Piping on VFM 3100 Performance

The flange size of the adjoining pipe must be the same nominal size

as the VFM 3100. Flanges with a smooth bore, similar to weld neck

flanges, are preferred.

Normal performance data is based on the use of Schedule 40 piping

upstream and downstream of the VFM 3100. If this is not the case,

the actual schedule must be selected from a picklist during configu-

ration and the distance to the disturbance in pipe diameters entered.

This enables the VFM 3100 to automatically compensate for any in-

duced flow effects.

In addition, the bore of the pipe (flange) and VFM 3100 must be

aligned (see "Installation Procedure" on page 12), and the flange

gaskets installed such that they do not protrude into the flow stream.

NOTE: 1. VFM 3100 mounted near pump discharge or suction lines

may be exposed to oscillatory flow that may affect vortex shedding

or product pipe vibration. Also, VFM 3100 mounted near the dis-

charge of a liquid positive displacement pump or near oscillating

control valves may experience severe flow fluctuations that could da-

mage the sensor. To avoid these adverse situations, install the VFM

3100 at least 20 feet or 40 pipe diameters, whichever is larger, from

the disturbance in question.

2. It is good piping practive that the internal surface of the pipe shall

be free from mill scale, pits, holes, reaming scores, rifling, bumps, or

other irregularities for four pipe diameters upstream and two pipe

diameters downstream of the VFM 3100.

Consideration for VFM 3100 Repair

When installing the VFM 3100, consider VFM 3100 repair. The

VFM 3100 should be accessible for servicing. If the flow cannot be

interrupted to replace a sensor, then an isolation manifold should be

mounted on the VFM 3100 before it is installed.

An acceptable and recommended practice is to install bypass

piping so that the entire VFM 3100 may be removed for servicing

(see Figure 4).

Liquid Control Installations

It is recommended for liquid flow that the VFM 3100 be mounted

upstream at least 5 pipe diameters from the control valve and in

vertical installations in the upward flowing leg. This will help to main-

tain a full pipe and ensure that there is sufficient back pressure to

prevent flashing or cavitation.

30 Pipe Diameters

recommended

5 Pipe Diameters

recommended

Shutoff Valves

Figure 4. Typical Piping Configuration