KROHNE VFM 3100 EN User Manual

Page 10

Gas Control Installations

For gas control installations, there are choices for VFM 3100 location

that should be considered. For maximum rangeability, locate the

VFM 3100 30 or more pipe diameters downstream from a control

valve. This will assure maximum velocity at the VFM 3100 and pro-

duce the most efficient signal from the sensor.

When the flow is more stable, the VFM 3100 may be mounted a mini-

mum of 5 pipe diameters upstream of the control valve. Pressure

fluctuations often are less on the upstream side of a control valve.

This should be considered as a means to provide the most accurate

density when a flow computer is not used.

The VFM 3100 electronics automatically calculates the effect of up-

stream piping on K-factor when installation piping data is entered by

user.

Steam Control Installations

For steam control installations, it is recommended that the VFM 3100

be mounted 30 pipe diameters or more downstream of the control

valve. This is particularly useful when measuring saturated steam to

ensure that there is a minimum amount of condensate present at the

VFM 3100.

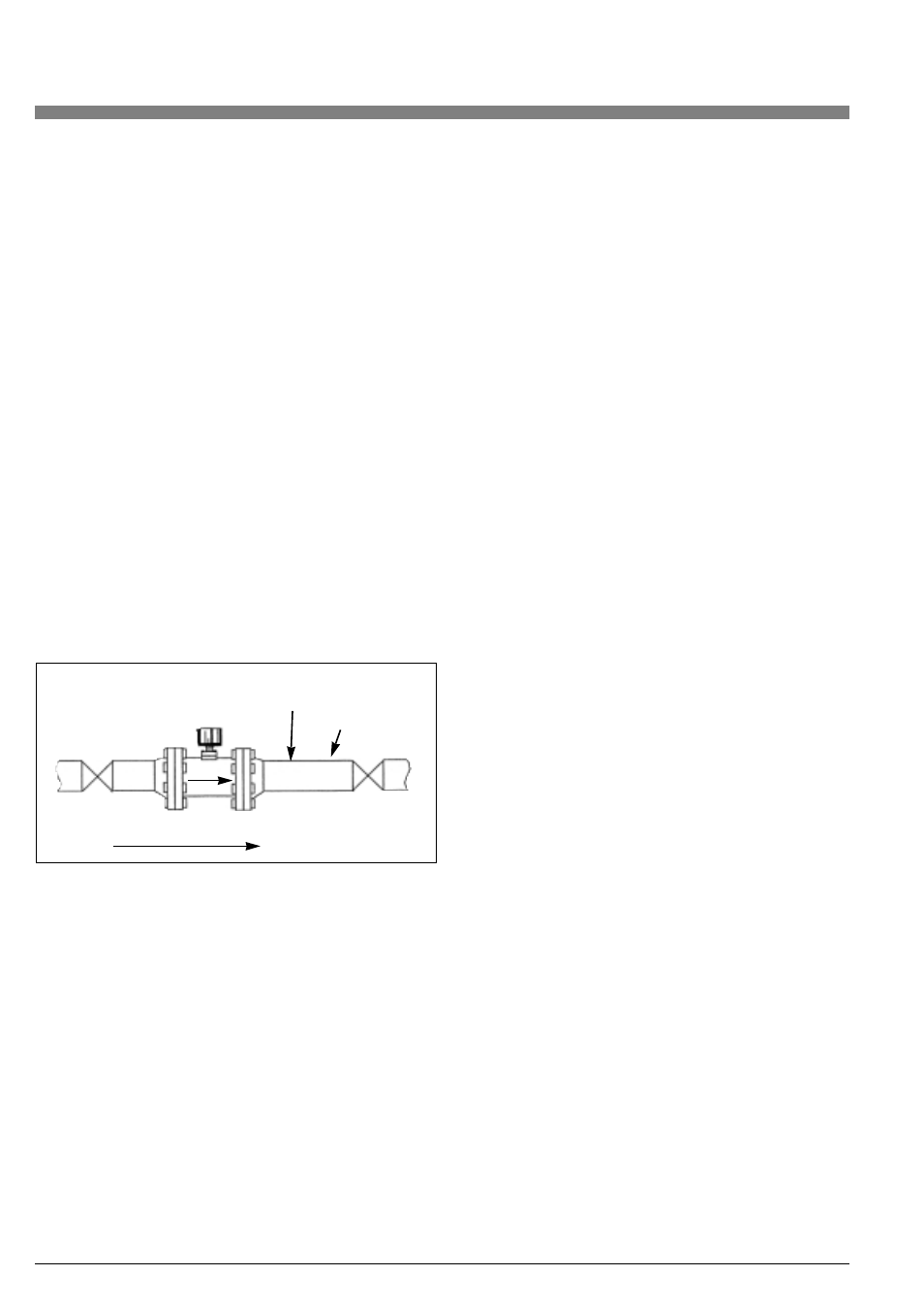

Pressure and Temperature Taps

NOTE: The inside of the pipe at the pressure and temperature taps

must be free of burrs and obstructions.

Pressure Taps -- For density measurement (when required),

locate the tap 3-1/2 to 4-1/2 pipe diameters DOWNSTREAM

of the VFM 3100. See Figure 5.

NOTE: On a gas installation, the pressure tap should be located on

the top of the pipe. On a liquid installation, the pressure tap (if requi-

red) should be located on the side of the pipe. On a steam installa-

tion, the pressure tap should be located on the top when the pressure

measuring device (typically a pressure transmitter) is above the

pipeline, and on the side when the measuring device is below the

pipeline. With vertical piping, the pressure tap may be located any-

where around the circumference of the pipeline.

Temperature Taps -- For temperature measurement (when re-

quired), locate the tap 5 to 6 pipe diameters DOWNSTREAM of

the VFM 3100. The smallest possible probe is recommended to

reduce flow disturbance. See Figure 5.

10

1.2.2. Installation Position

For optimal performance the locations of the sensor and integral

electronics relative to the piping must be considered. Factors that

influence this decision include process fluid type, ambient tempera-

ture, and vibration.

Process Fluid

When using:

Saturated Steam: The electronics housing should be below the

VFM 3100 body, so that the sensor cavity remains filled with conden-

sate.

NOTE: A VFM3100 used on steam should be located downstream

of a control valve.See "Steam Control Installations."

Superheated Steam: The electronics housing should be below the

VFM 3100 body when the steam has less than 10 °F (5.6 °C) super-

heat. The housing should be above the VFM 3100 body when the

superheat is more than 10 °F and no condensate will be forming on

the sensor. An isolation valve may be used in superheated steam

applications with adequate insulation.

Gas: The electronics housing may be above or below the VFM 3100

body. The normal recommended position of the electronics housing

is above the VFM 3100 body.

Liquid: For a liquid with solid particles, the electronics housing

should be above the VFM 3100 body. Care should be taken so that

entrapped air does not accumulate in the sensor cavity. For a clean

liquid, the electronics housing may be mounted below the VFM 3100

body. Care must be taken if there is any sediment or fine dirt, that the

particles do not accumulate in the sensor cavity. A VFM 3100 used

on liquid should be mounted upstream from a control valve.

VFM 3100 may also be mounted with the electronics housing posi-

tioned to the side. This ensures escape of entrapped air and mini-

mizes sediment accumulation.

The above considerations are summarized in Table 3 for single and

dual measurement VFM 3100 with and without isolation valves.

1.2.3. Ambient Temperature

Ambient temperature limits must be observed per specifications.

However, if the electronic housing is above the ambient temperature

limit (85 °C, 185 °F), the VFM 3100 may be mounted with the electro-

nic housing located to the side to aid the cooling of the electronic

module. The bottom conduit connection shoud be used (the top one

plugged) to avoid possible accumulation of condensate at the termi-

nal block.

1.2.4. Vibration

The vortex shedder axis should be oriented to reduce or, in some ca-

ses virtually eliminate, vibration influence. Positioning VFM3100 so

that vibrations are parallel to sensor diaphragms will minimize effect

of vibrations.

Pressure Tap

Temperature Tap

Direction of Flow

Figure 5. Pressure and Temperature Tap Locations