Sensor test procedure, Maintenance 4.1. introduction – KROHNE VFM 3100 EN User Manual

Page 29

3.5. Sensor Test Procedure

3.5.1. Standard Temperature Range Sensor

•

Remove electronic module from housing.

•

Disconnect the yellow and brown sensor leads from back

of electronic module.

•

Connect sensor lead to an oscilloscope.

•

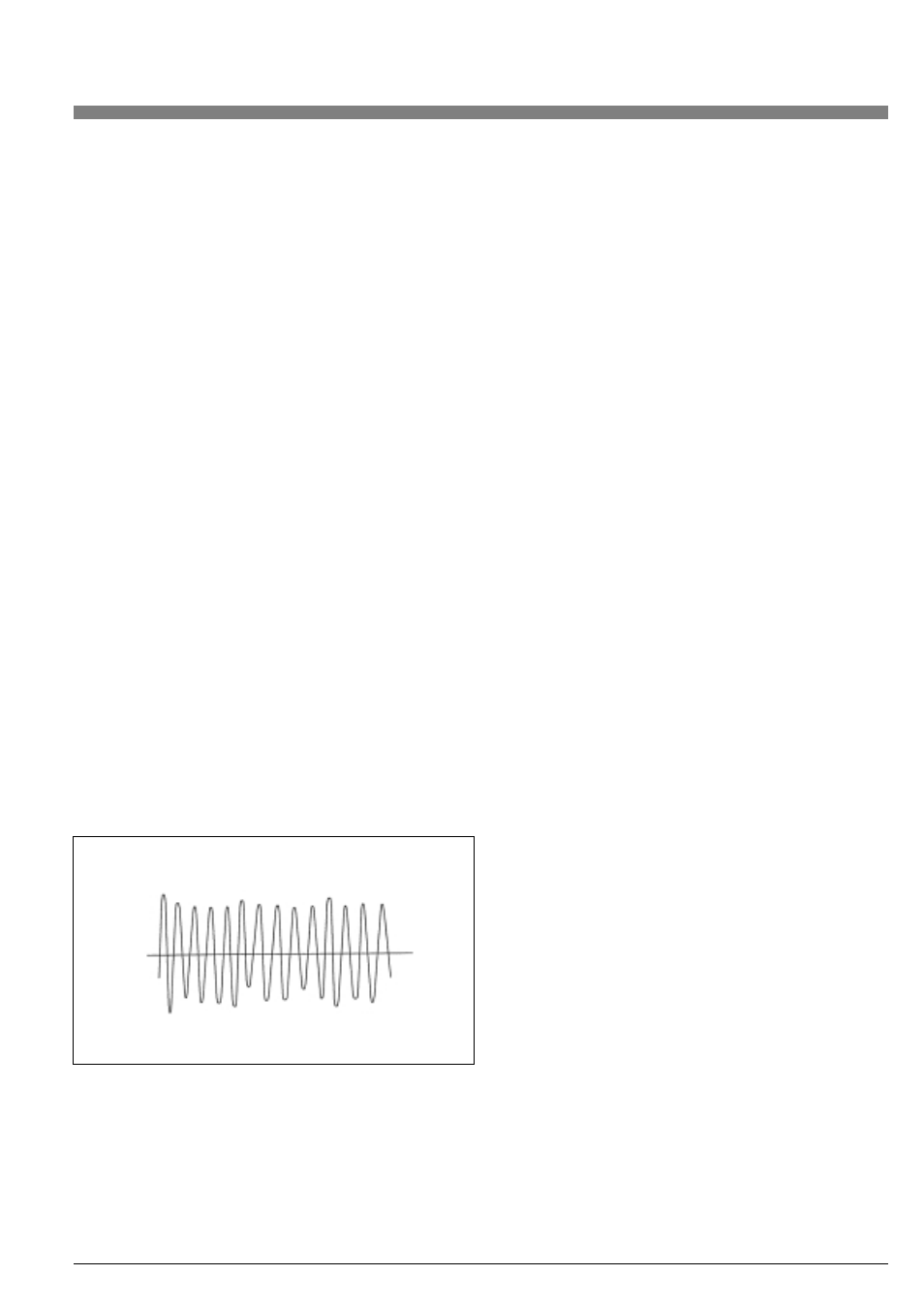

With fluid flow in the pipe, observe signal waveform on

oscilloscope. Waveform should be similar to that shown in

Figure 15.

a. If waveform is similar to Figure 15, the sensor is good. If there

is no output from the electronic module, the electronic module

input stage has failed. The entire electronic module should be

replaced.

b. If there is no sensor output signal, the sensor has failed and

should be replaced. See “Sensor Replacement with Integral

Electronic Module” on page 37 for details.

3.5.2. Extended Temperature Range Sensor

•

Remove the electronic module from the housing. Remove the

preamplifier from the housing. First, pry the ears of the metal

shield away from the sides of the housing. Then lift out the shield

assembly.

•

Disconnect the brown and yellow sensor leads from the pream-

plifier input terminal strip.

•

With flow in the pipe, use an oscilloscope to observe the sensor

output. The scope probe impedance must be 10 megohms or

greater. The waveform should be similar to that shown in Figure

15. When the preamplifier is not in the circuit, the minimum

signal required for the sensor is about 2.5 mV.

For liquid flow, the minimum signal of 2.5 mV will require about

25 Hz. Be sure that flow is enough to produce 25 Hz.

For gas or steam flow, the minimum signal of 2.5 mV may require

100 Hz or more, depending on meter size.

If the waveform is similar to Figure 15, the sensor is functioning.

If there is no output, replace the sensor.

NOTE: For all sensors, be sure the signal being read is not the local

power line frequency, i.e., 50 or 60 Hz.

29

Figure 15. Normal VFM 3100 Frequency Waveform

4. Maintenance

4.1. Introduction

The operation of the VFM 3100 consists of three basic functions:

generation and shedding of vortices in the fluid stream, sensing of

vortices, and amplification, conditioning, and processing of the

signal from the vortex sensor. Should a malfunction of the VFM 3100

be suspected, the cause can normally be isolated to one of these

three functions.

Personnel involved in maintenance of VFM 3100 should be trained

and qualified in the use of the equipment required and in the removal

and replacement of the VFM 3100 in the piping. They should also be

qualified for the routine maintenance of the VFM 3100 components.

4.1.1. Vortex Generation and Shedding

The process of vortex generation and shedding can be degraded or

destroyed by disturbances in the upstream flow, the nature of the flo-

wing fluid, or by damage to the vortex shedding element (rare). Such

flow disturbances may be created by gaskets protruding into the flo-

wing stream, by some form of partial blockage in the upstream pi-

ping, by the piping configuration, or by the existence of two-phase

flow. Should the vortex shedding element become heavily caked,

coated, or physically damaged to the extent that its basic shape or

dimensions are changed, the vortex shedding process may be im-

paired. Also, the length of straight, unobstructed run of upstream pi-

ping is important (refer to “Piping Considerations” on page 9).

4.1.2. Vortex Sensing

There are two basic types of sensors employed by the VFM 3100 -

Standard Temperature and Extended Temperature Range. The

Standard Temperature Range sensor may be filled with Fluorolube

Temperature Range sensor is an unfilled sensor for applications to

430 °C (800 °F).

The Standard Temperature Range sensor consists of a piezoelectric

bimorph crystal that is sealed inside a liquid-filled capsule having two

diaphragms on opposing sides. The vortex shedding process

creates an alternating differential pressure across the capsule that is

transmitted via the diaphragms and fill-fluid to the crystal.

The Extended Temperature Range sensor consists of two piezoelec-

tric crystals sealed inside a capsule having two process diaphragms,

on opposing sides, connected internally by a mechanical shuttle.

The vortex shedding process creates an alternating differential

pressure across the capsule that is transmitted via the diaphragm-

shuttle mechanism to the crystals.

The alternating force acting on the crystals causes them to develop

a pulsed voltage with a frequency equal to the vortex shedding

frequency. Damage to sealing diaphragms or other physical damage

could cause the sensors to operate improperly.

4.1.3. Amplification, Conditioning and Processing

The vortex sensor signal is amplified, conditioned, and processed in

the electronic module, which is located in the compartment of the el-

ectrical housing. In addition, the electronic module generates digital,

4 to 20 mA, and scaled pulse output signals. A simplified block dia-

gram of the VFM 3100 is shown in Figure 16.

As shown, the electronic module accepts the raw sensor output

directly from Standard Temperature Range sensors. When used with

an Extended Temperature Range sensor, the raw sensor output

must be buffered by a preamplifier before being passed to the

electronic module. The preamplifier is also used with the standard

temperature range sensor in remote installations. A switch on the

preamplifier is used to match impedance to the sensor. In either ca-

se, the electronic module receives and processes the vortex signal

and provides the various output signals.