KROHNE VFM 3100 EN User Manual

Page 12

12

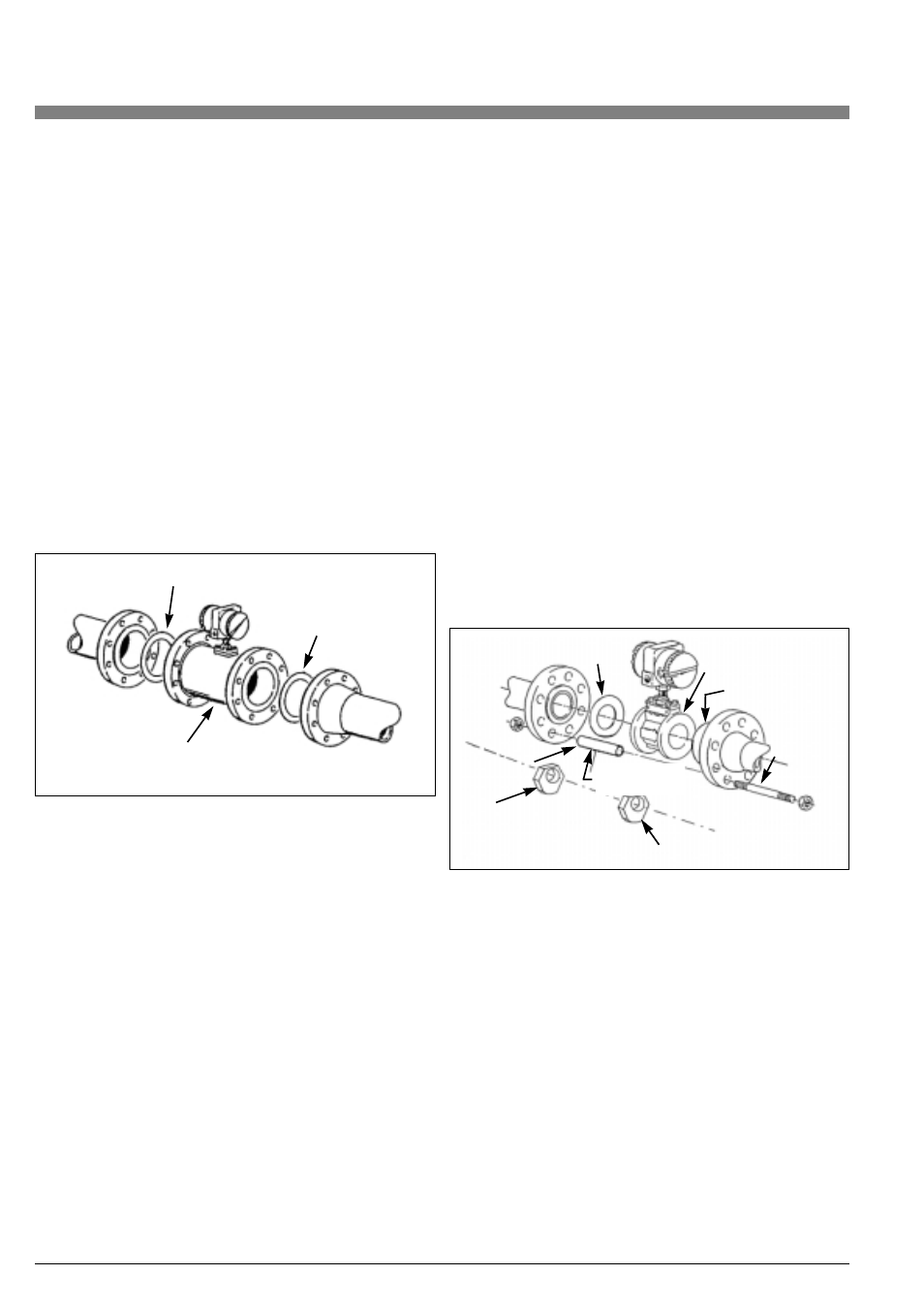

1.2.5. Installation Procedure

VFM 3100 F–Flanged Body

•

Gaskets are required and must be supplied by the user.

Select a gasket material suitable for the process.

•

Insert gaskets between body of VFM 3100 and adjacent

flanges. See Figure 6. Position gaskets so that ID of each

gasket is centered on ID of VFM 3100 and adjacent piping.

CAUTION:

•

Verify that the ID of the gaskets is larger than that of the VFM

3100 bore and pipe and that they do not protrude into the

VFM 3100 entrance or exit. Accuracy of the measurement will

be affected.

•

Gaskets will not prevent flanges from being wetted by process

fluids.

NOTE: When installing new flanges in the process piping and the

VFM 3100 is used as a gauge to set the flanges, the inside diameter

of the VFM 3100 must be protected from weld splatter. It is recom-

mended that a solid sheet of gasketing be installed at each end of the

VFM 3100 during welding. Remove this sheet and install flange gas-

ket after welding. Remove any splatter in either the pipe or the VFM

3100 as this could affect VFM 3100 accuracy.

•

Visually inspect for concentricity of mating flanges.

•

Tighten bolts in accordance with conventional flange bolt

tightening practice (i.e., incremental and alternate tightening

of bolts).

VFM 3100 W– Sandwich Body

For optimal performance, the sandwich body VFM 3100 should be

centered with respect to the adjoining pipe. Normally, this requires

the use of centering fixtures that are supplied with the VFM 3100.

NOTE: Centering fixtures are not required for meters with ANSI

Class 150 flanges.

Two types of centering fixtures are presently in use; the older cente-

ring sleeves and the newer hex-nut spacers. The VFM 3100 may

come with either type of fixture. Most meter sizes have two centering

fixtures (two sets in the case of the hex-nut spaceres), but some lar-

ger sizes may have twice this number, two for each side.

•

See Figure 7. Insert the first stud through the downstream

flange at one of the lower holes, through the centering sleeves

or two hex-nut spacers, and then through the upstream flange.

Place the nuts on both ends of the stud but do not tighten.

•

Using the remaining centering sleeve or hex-nut spacers,

repeat Step 1 at the lower hole adjacent to the first.

•

Set the VFM 3100 between the flanges. For centering with the

hex-nut spacers, rotate spacers to the thickness that centers

the VFM 3100.

NOTE: By rotating the hex-nut spacers to the correct thickness, you

can center the VFM 3100 to any type of flange.

•

Gaskets are required and must be supplied by the user.

Select a gasket material suitable for the process fluid.

•

Insert gaskets between body of VFM 3100 and adjacent

flanges. Position gaskets so that ID of each gasket is centered

on ID of VFM 3100 and adjacent piping.

CAUTION: Verify that the ID of the gaskets is larger than that of

the VFM 3100 bore and pipe and that they do not protrude into the

VFM 3100 entrance or exit.

NOTE: If welding of flanges to the process piping is required, protect

the VFM 3100 from weld splatter, which could affect VFM 3100

accuracy. It is recommended that a solid sheet of gasketing be instal-

led at each end of the VFM 3100 during welding. Remove this sheet

and install flange gasket after welding.

•

Visually inspect for concentricity of mating flanges.

•

Install the rest of the studs and nuts and tighten the nuts in

accordance with conventional flange bolt tightening practice

(i.e., incremental and alternate tightening of bolts).

1.2.6. Repositioning the Electrical Housing

The VFM 3100 housing may be repositioned up to a maximum of

270°C from its original position by rotating the electrical housing.

WARNING: Stops are incorporated in the housing design. Do not

remove the stops as further rotation from the 270°C maximum may

cause damage to the sensor wires. Additionally this may violate sa-

fety code requirements for explosion-proof thread engagement in

hazardous locations.

•

Unscrew housing locknut to bottom of thread. See figure 8.

• Square locking plate should slip down on shaft. If it does not,

pry out with scewdriver.

•

Rotate electrical housing to desired position.

See Warning on page 12.

• Note recess on bottom of electrical housing into which the

locking plate fits. Screw the locking nut hand tight making sure

locking plate fits into recess on bottom of electrical housing.

•

Secure the locknut firmly using a wrench.

Gasket

Gasket

VFM 3100

Gasket

Gasket

Install centering

fixtures on

adjacent lower

studs of flange

VFM 3100

2 hex-nut spacers

per side (not required

with class 150)

Hex-nut alignment device

(not required with class 150)

Centering sleeve

(not required with

class 150)

Figure 6. VFM 3100 F Installation

Figure 7. VFM 3100 W Centering (using Spacers OR Sleeves)

Larger meters

have 2 centering

fixtures per side