KROHNE VFM 3100 EN User Manual

Page 42

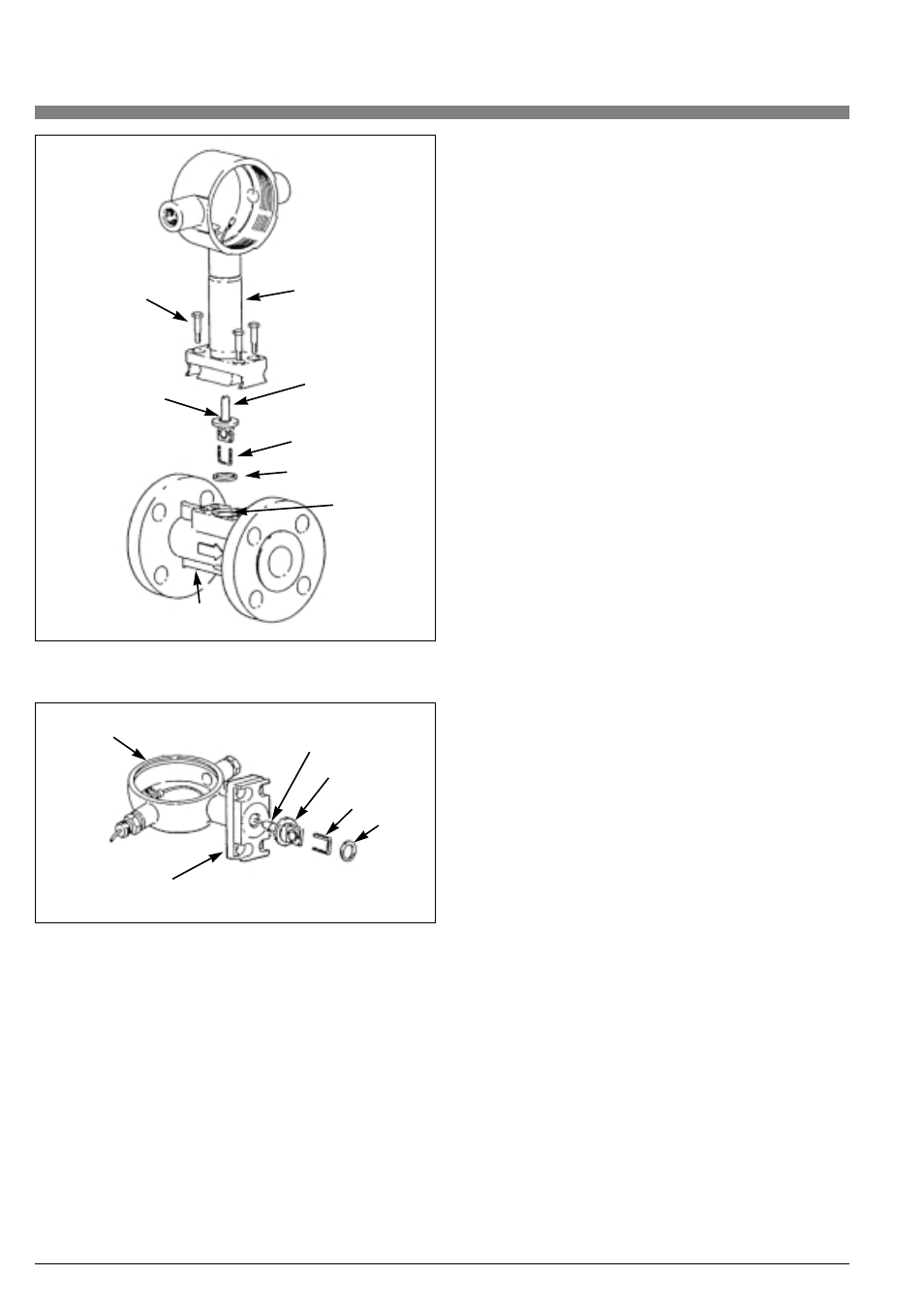

4.7.2. Assembly

NOTE: Before beginning the assembly procedure, verify that you ha-

ve the correct kit of parts.

The sensor kits consist of:

1 Sensor Assembly

1 O-ring

1 Gasket

1 Flow Dam

Slide O-ring over sensor lead and onto neck of sensor.

See Figure 29.

The following steps apply to both Standard and Extended Tempera-

ture Range VFM 3100:

•

If the flow dam has remained in the VFM 3100 body, remove it

before starting to reassemble.

•

Carefully feed sensor lead through hole in mechanical connector

and gently pull sensor lead out of junction box until sensor is

touching the mechanical connector. See Figure 37.

CAUTION: For CENELEC certified flameproof units, take special

care not to scar, mar, ding, or dent the surface of the sensor stem

during assembly. This is critical to the integrity of the flameproof sur-

face finish.

•

Place the flat gasket over the sensor in contact with the serrated

sealing surface. Center the gasket. Slide the flow dam into the

groove on the sensor.

•

Insert the sensor with the connector into the VFM 3100 body

and assemble the four bolts finger tight.

WARNING: It is important that the gasket be sealed uniformly to

provide a good seal. The following steps will assure a uniform seal.

Failure to follow these steps could result in personal injury due to

gasket leakage.

•

Tighten all connector bolts to 3.4 Nm (25 lb•ft) per the

procedure starting on page 40. Refer to Figures 32 and 33.

•

Attach conduit connections and input wiring. See “Field

Termination” on page 19.

NOTE: Replacing the sensor will not cause a shift in the K-factor.

Therefore, the VFM 3100 does not require recalibration.

•

Connect the sensor wires to the color coded terminals as shown

in Figure 34 for the Standard Temperature Range sensor and in

Figure 35 for the Extended Temperature Range sensor.

WARNING: In order to maintain agency certification of this product

and prove integrity of the parts and workmanship in containing pro-

cess pressure, a hydrostatic pressure test must be performed. The

VFM 3100 must hold for 1 minute without leaking the appropriate

pressure from Table 11, “Maximum Test Pressure,” on page 40.

42

Mechanical

connector

bolts (4)

Mechanical

connector

Sensor

assembly

Flow dam

Gasket

Sensor

assembly

O-Ring

Flow dam

Gasket

Access hole

Body

O-Ring

Junction box

Mechanical connector

Figure 36. VFM 3100 Assembly/Junction Box

Figure 37. Sensor/Mechanical Connector/Junction Box