KROHNE VFM 3100 EN User Manual

Page 8

8

After removing the flowtube from its shipping carton, inspect it for

visible damage. If any damage is observed, notify the carrier imme-

diately and request an inspection report. Obtain a signed copy of the

report form the carrier. The calibration certificate and any other docu-

mentation shipped with the VFM 3100 should be separated from the

packing material and held for future reference. Re-install any flange

covers or protective material to safeguard the VFM 3100 until it is in-

stalled.

Packing material should be disposed of in accordance with local

regulations. All packing material is non-hazardous and is generally

acceptable to landfills.

1.1.6. VFM 3100 Identification

The model code is stamped on the data plate as shown in Figure 3

and is digitally readable from the configuration menu.

The Standard Temperature Range sensor is made of 316 stainless

steel and is filled with silicone oil, maximum temperature 200 °C

(400 °F). An optional fill is Fluorolube, maximum temperature 90 °C

(200 °F). The Extended Temperature Range sensor is made of 316

stainless steel and is unfilled, maximum temperature 430 °C (800 °F).

Both standard and high temperature sensors are available made

from Hastelloy.

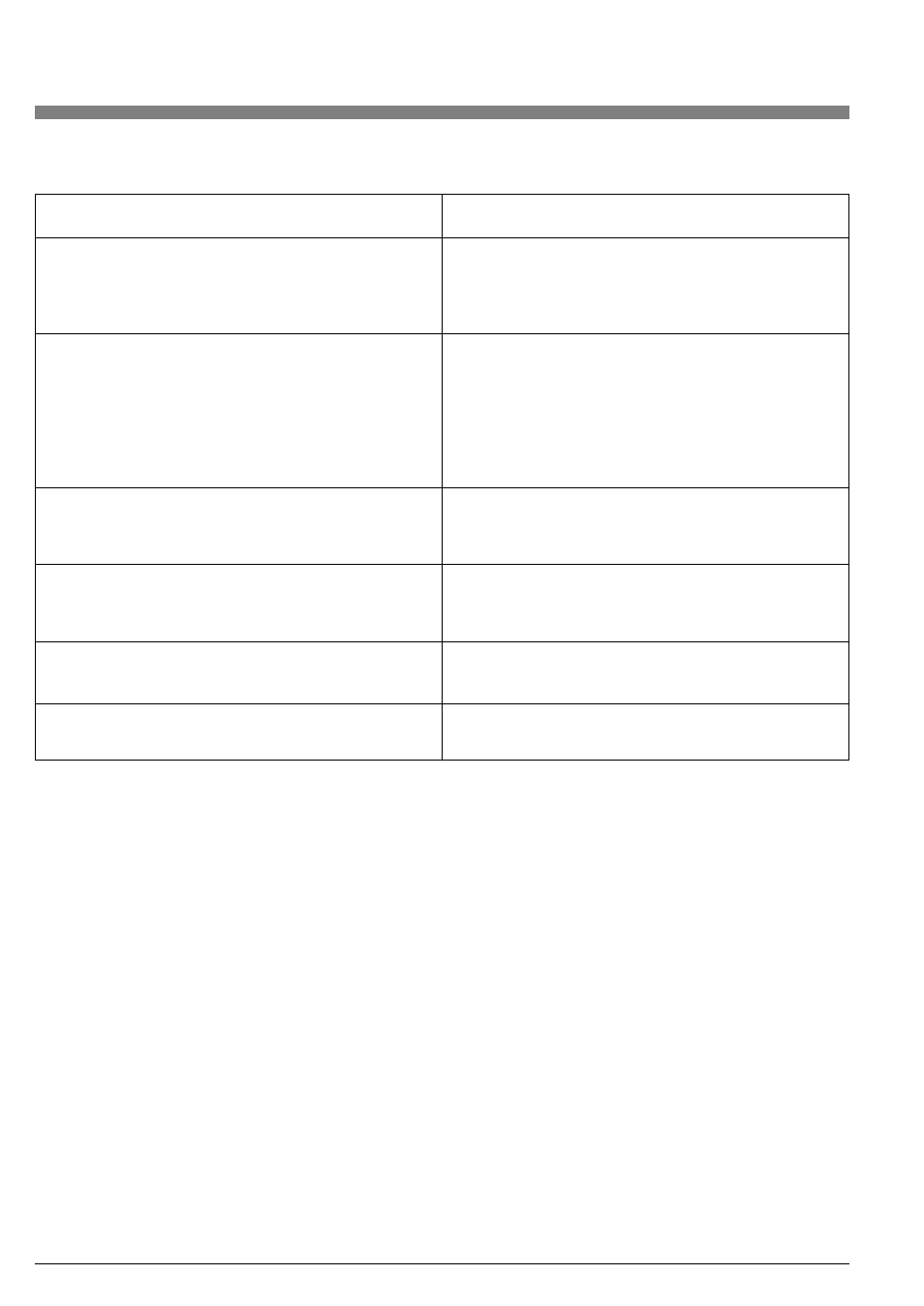

1.1.4. Electrical Safety Specifications

Table 2.

CSA

intrinsically safe for Class I, Division I,

Groups A, B, C, D; Class II, Division I,

Groups E, F, G: and Class III, Division I

CSA explosionproof for Class I, Division I,

Groups C and D; dust-ignitionproof for Class II

and III, Division I, Groups E, F,

and G; and Class III, Division I.

Suitable for Class I, Division 2,

Groups A, B, C, D; class II, Division 2,

Groups F, G; and Class III, Division 2.

FM intrinsically safe for Class I, II and III,

Division 1, Group A, B, C, D, E, F, and G;

nonincendive Class I, II and III, Division 2,

Groups A, B, C, D, F, and G.

FM explosionproof for Class I, Division 1, Groups C

and D; dust-ignitionproof for Class II and III, Division 1,

Groups E, F, and G; nonincendive Class I, II and III,

Division 2, Groups A, B, C, D, F, and G.

CENELEC intrinsically safe for EEX ib,

Gas Group IIC, Zone 1.

CENELEC flameproof for EEx d (ib), Gas, Group IIC,

Zone 1

Testing Laboratory, Type of Protection,

and Area Classification

Temperature Class T3C at 85°C and

T4A at 40°C maximum ambient.

Limited to Gas Groups C and D when

connected to 33 V, 185

Ω Zener

barrier.

Temperature Class T5.

Temperature Class T3C at 85°C and

T4A at 40°C maximum ambient.

Temperature Class T5.

Temperature Class T4 at 0.8 W.

Temperature Class T5 at 0.5 W.

Temperature Class T6 at 0.3 W.

Temperature Class T6.

Application Conditions

NOTE: These transmitters have been designed to meet the electri-

cal safety descriptions listed in the table above. For detailed infor-

mation or status of testing laboratory approvals/ certifications,

contact KROHNE.

1.1.5. Unpacking

The VFM 3100 is built to be durable, but it is part of a calibrated

precision system and should be handled as such.

NOTE: VFM 3100 may (depending on pressure rating of flanges

with which they will be used) have a set of centering spacers inclu-

ded. Do not discard these centering spacers. They must be used

to install the VFM 3100 properly.

VFM 3100 with remote-mounted electronics are rugged two-piece

units. A remote cable connection is assembled to the VFM 3100

junction box and electronics housing. The cable may be cut to the

required length per instructions beginning on page 13. Do not allow

the weight of either the flowtube or electronics housing to be sup-

ported by the remote cable.

Remove the flowtube from the shipping carton using care to avoid

dropping or otherwise subjecting it to impact, particularly at the

flange or wafer faces. Never put anything through the flowtube for

lifting purposes as damage to the shedder bar may occur.