Latching or non-latching relays, I/o module installation, Figure 10 i/o module installation – Detcon MCX-32-N4X User Manual

Page 20: 5 i/o module installation, 3 latching or non-latching relays

Model MCX-32

Model MCX-32 Instruction Manual

Rev.2.3

Page 14 of 49

the corresponding relay, once activated, can be deactivated by pressing the Alarm Silence button on the left

edge of the screen.

4.4.3

Latching or Non-Latching Relays

All alarms - Alarm 1, Alarm 2, Alarm 3, and Fault - can be configured as either latching or non-latching. In

non-latching mode, the relay is deactivated as soon as the sensor alarm (alarm relays) or fault (fault relay)

condition is cleared. In latching mode, the relay remains active even after the alarm or fault condition has

cleared. Once activated, the relay can only be deactivated by pressing the Alarm Reset button on the left edge

of the screen after the alarm or fault condition has cleared.

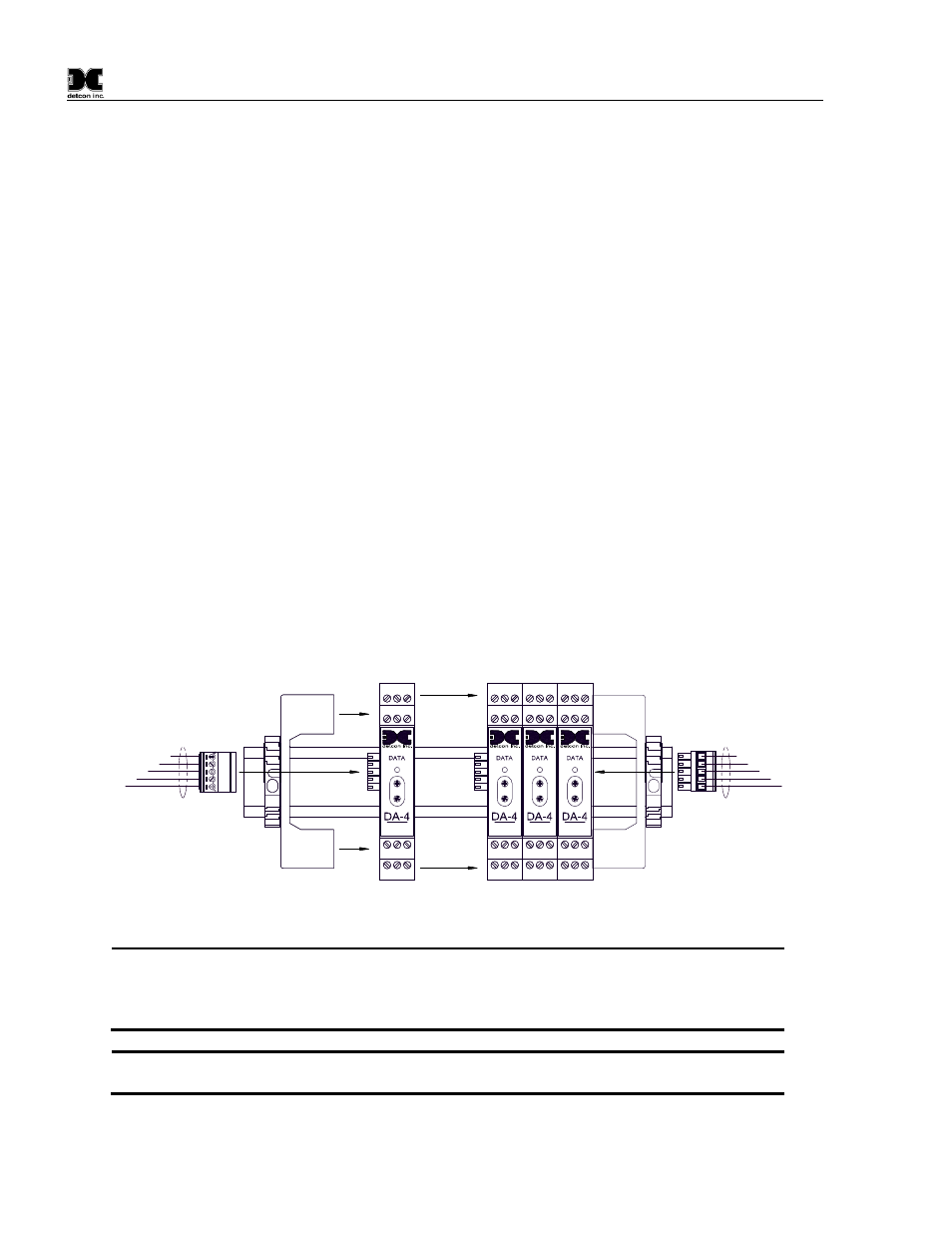

4.5 I/O Module Installation

The quantity of I/O modules supported by the MCX-32 controller will vary depending on the enclosure type

chosen due to physical space limitations. A maximum of 2 I/O modules may be installed on the Model MCX-

32-N1P enclosure. A maximum of 16 I/O modules may be installed in the Model MCX-32-N4X enclosure

(Four modules can be installed on DIN rail TB1 and 12 can be installed on DIN rail TB2).

Additional

modules will need to be mounted in a separate enclosure by the customer.

I/O modules are mounted on an industry-standard 37.5 x 7.5 mm DIN rail (See Figure 10). Install the first I/O

module at the end of the DIN rail nearest the male connector. Plug the male connector into the side of the

module. Slide it all the way to the end stop. Add additional modules next to the first module. When installing

additional I/O modules, make sure there is about 0.5 inch clearance on either side of the module and snap the

module onto the DIN rail (the 0.5” spacing is to allow for connector clearance). Once the I/O module is

snapped onto the DIN rail, slide it towards the adjacent module and assure that it firmly plugs into it. Connect

the RS-485 and power female connector to the last module installed on the DIN rail. Secure the modules with

an end stop.

S

B

A

-

+

+

RS-485 and

Power Cable

RS-485 and Power

Cable from Output

Terminal Blocks.

Add additional modules

as needed.

Female

Connector

Male

Connector

4-20mA

INPUT

COMM

M

S

D

L

S

D

4-20mA

INPUT

COMM

M

S

D

L

S

D

4-20mA

INPUT

COMM

M

S

D

L

S

D

4-20mA

INPUT

COMM

M

S

D

L

S

D

End Stop

End Stop

S

B

A

-

+

S

B

A

-

Figure 10 I/O Module Installation

NOTE: The male connector must be plugged into the I/O module at one end of the DIN rail

and the female connector must be plugged into the I/O module at the other end of the stack of

I/O modules. If these connectors are not properly installed, communication with other RS-485

devices will not be possible.

NOTE: If no I/O modules are installed in the controller, the male connector must be plugged

into the female connector for the RS-485 to communicate.

For addressable I/O modules or Modbus™ sensors that are being located remotely from the controller, General

Cable Commodore p/n ZO16P0022189 is recommended for serial and power connections.