2 replacement of intelligent plug-in sensor, Replacement of intelligent plug-in sensor, Figure 26 replacing the cap – Detcon PI-700 0-500ppb User Manual

Page 37: Figure 27 sensor assembly

Model PI-700 0-500ppb

PI-700 0-500ppb Instruction Manual

Rev. 0.0

Page 33 of 53

6. Align the Cap Key with the notch on the housing. Starting at the side opposite the notch, press down until

the Filter Cap snaps on to the housing. If the Cap Key is incorrectly aligned there will be a noticeable

bulge on the side of the cap.

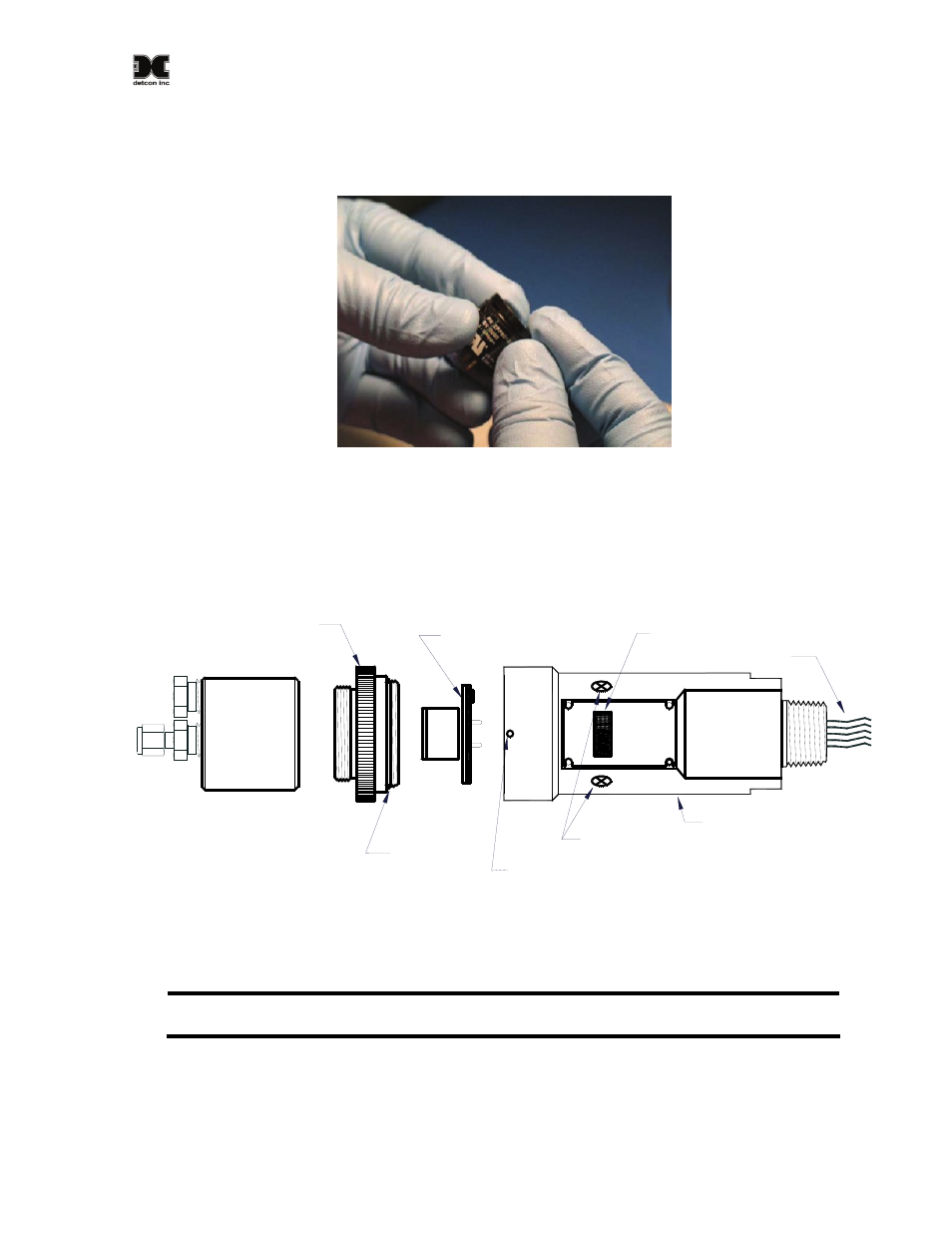

Figure 27 Replacing the Cap

Visual Inspection

The Sensor should be inspected annually. Inspect for signs of corrosion, pitting, and water damage. During

visual inspection, the Sample Chamber should be inspected to insure that it is not blocked. Examine the plug-

in sensor for signs of physical blockage, electrolyte leakage, or severe corrosion. Also, inspect inside the

Junction Box for signs of water accumulation or Terminal Block corrosion.

O-Ring

Sample

Chamber

Housing Bottom

Locking Set-Screw

Intelligent Transmitter Module

(ITM)

Micro-processor controlled circuitry

enclosed in an explosion-proof

housing

MOD

E

L

PI-

700

PG

M

2

S

PAN

VOC

de

tc

on in

c.

Replaceable Intelligent

Plug-in Sensor

ZER

O

PGM

1

Interconnect Wires

Magnetic Programming

Switches

Lens and LED Display

SS Splash

Guard

Adapter

Figure 28 Sensor Assembly

5.2 Replacement of Intelligent Plug-in Sensor

NOTE: It is not necessary to remove power while changing the Intelligent plug-in VOC gas

sensor in order to maintain area classification, since it is intrinsically safe.

a) Use a 1/16” Allen wrench to release the locking setscrew that locks the ITM and Splash Guard Adapter

together (One turn will suffice - Do not remove setscrew completely).

b) Unthread and remove the Splash Guard Adapter and Sample Chamber from the ITM.