5 electrical installation, 6 field wiring, Electrical installation – Detcon PI-700 0-500ppb User Manual

Page 11: Field wiring

Model PI-700 0-500ppb

PI-700 0-500ppb Instruction Manual

Rev. 0.0

Page 7 of 53

2.5 Electrical Installation

The Sensor Assembly should be installed in accordance with local electrical codes. The sensor assemblies are

designed for Class I, Division 1, Groups B, C, & D area classifications, and for ATEX Class I, Zone 1, Group

IIC area classifications.

Proper electrical installation of the gas sensor is critical for conformance to Electrical Codes. Refer to Figure

8 for proper electrical installation.

2.6 Field Wiring

Detcon Model PI-700 toxic gas sensors assemblies require three conductor connections between power

supplies and host electronic controller’s 4-20mA output, and two conductor connections for the Modbus™ RS-

485 serial interface. Wiring designations are + (DC), – (DC), mA (sensor signal), and Modbus™ RS-485 A

(+), and B(-). Maximum wire length between sensor and 24VDC source is shown in the Table 1 below.

Maximum wire size for termination in the Detcon J-Box accessory is 14 gauge.

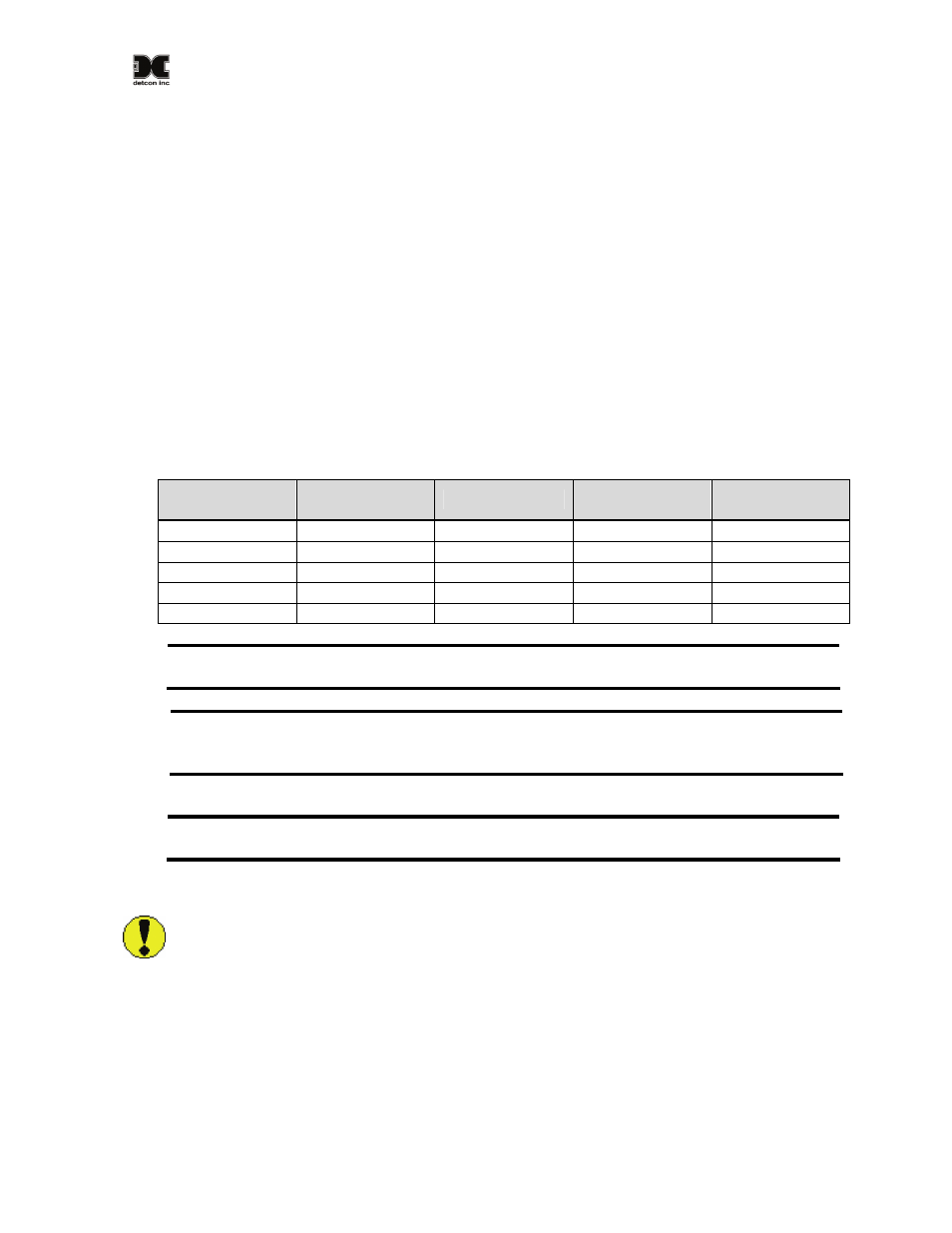

Table 1 Wire Gauge vs. Distance

AWG

Wire Dia.

Meters

Feet

Over-Current

Protection

22 0.723mm 700 2080 3A

20 0.812mm 1120 3350 5A

18 1.024mm 1750 5250 7A

16 1.291mm 2800 8400 10A

14 1.628mm 4480 13,440 20A

NOTE 1: Wiring table is based on stranded tinned copper wire and is designed to serve as a

reference only.

NOTE 2: Shielded cable is required for installations where cable trays or conduit runs include

high voltage lines or other possible sources of induced interference. Separate conduit runs are

highly recommended in these cases.

NOTE 3: The supply of power should be from an isolated source with over-current protection

as stipulated in table.

Terminal Connections

CAUTION: Do not apply System power to the sensor until all wiring is properly terminated. Refer

to Section 2.7 Initial Start Up