7 initial start up, Initial start up, Figure 8 sensor wire connections – Detcon PI-700 0-500ppb User Manual

Page 12

Model PI-700 0-500ppb

PI-700 0-500ppb Instruction Manual

Rev. 0.0

Page 8 of 53

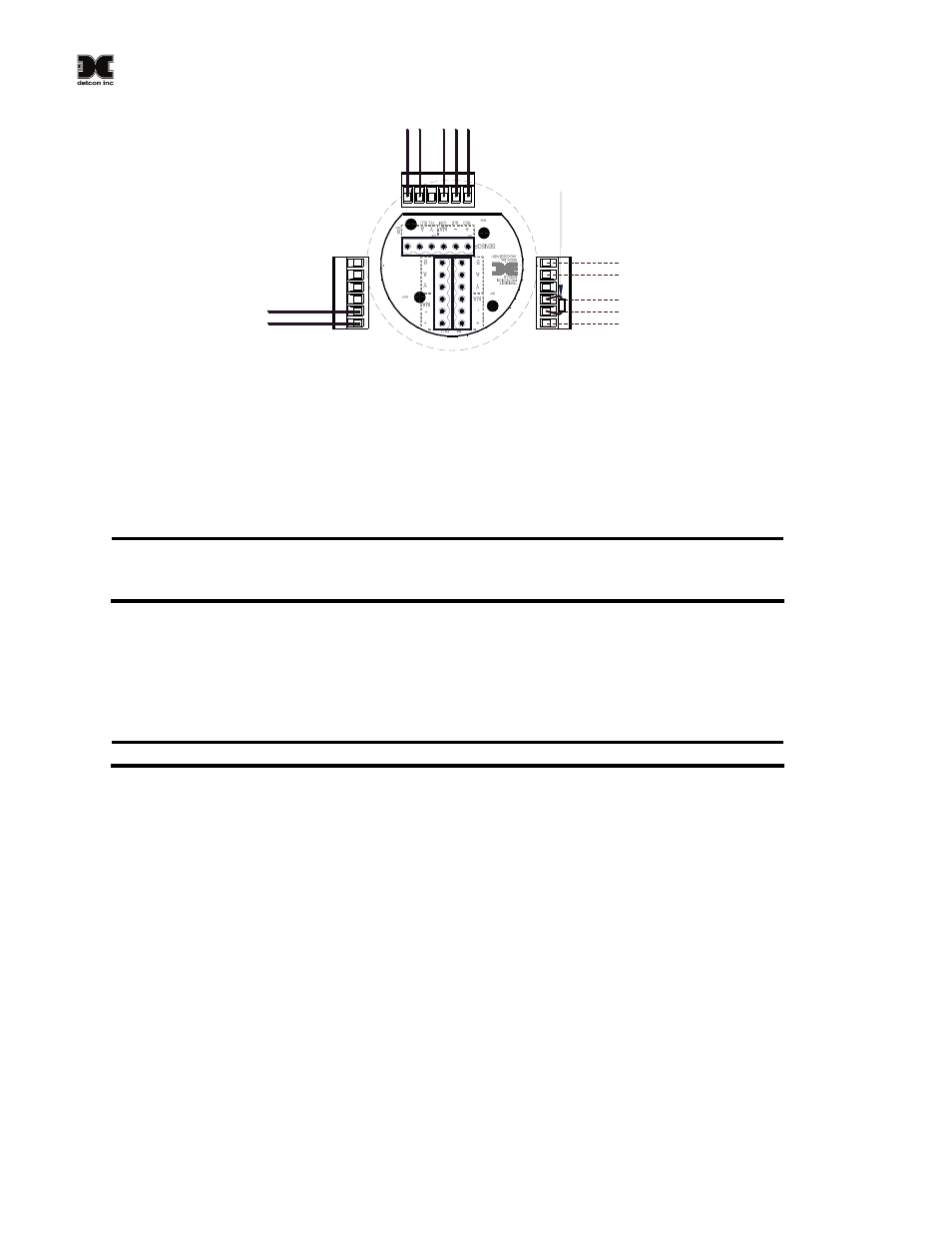

Wiring to

Sensor Assembly

Mini Condulet

Wiring to Pump

Customer

Supplied Wiring (In)

RS-485 connections,

Power, and 4-20mA to

Control Device

(+) Red

(-) Black

(+)

(-)

mA

A(+)

B(-)

R

ed

(+)

B

lack

(-)

G

reen

mA

Bl

ue A

(+

)

W

hite

B(

-)

Install a 100-250 Ohm

resistor if the 4-20mA

output is not used

Figure 8 Sensor Wire Connections

a) Remove the junction box cover. Identify the terminal blocks for customer wire connections.

b) Observing correct polarity, terminate the 3-conductor 4-20mA field wiring (+, -, mA) to the sensor

assembly wiring in accordance with the detail shown in Figure 8. If the 4-20mA output is not used,

install a 100-250Ω resistor between the mA and (-) terminals on the Transient Protection Module.

NOTE: If the 4-20mA output is not being used, a 100-250Ω resistor must be installed between

the mA and (-) terminals on the Transient Protection Module to ensure RS-485 communication

is not disrupted by a 4-20mA Fault.

a) If applicable, terminate the RS-485 serial wiring as shown in Figure 8. Use the second plug (Out) as

termination point on the customer side to facilitate a continuous RS-485 serial loop.

The RS-485 (if applicable) requires 24 gauge, two conductor, shielded, twisted pair cable between the sensor

and host. Belden Cable part number 9841 is recommended.

NOTE: Install a 120-ohm resistor across A & B terminals on the last sensor in the serial loop.

c) Trim all exposed wire leads if they are not permanently landed in the terminal block.

d) Replace the junction box cover.

2.7 Initial Start Up

Upon completion of all mechanical mounting and termination of all field wiring, apply system power in the

range of 11.5-30VDC (24VDC typical) and observe the following normal conditions:

a) PI-700 display reads close to “0”, and no fault messages are flashing.

b) Note that the Pump is operating. The pump should operate continually.

c) A temporary upscale or downscale reading may occur as the sensor stabilizes. This upscale reading will

typically decrease to near “0”ppm within 1-2 minutes of power-up, assuming there is no gas in the area of

the sensor. In some extreme cases, the sensor may require up to 5 minutes before the lamp ignites and

becomes operational.