5 maintenance, 1 recommended boilerspection maintenance schedule, 1 inspection and test – LumaSense Technologies BoilerSpection-IM Manual User Manual

Page 25: 2 preventive maintenance, 2 spare parts, Inspection and test, Preventive maintenance

BoilerSpection IM Manual

Maintenance 25

5 Maintenance

The BoilerSpection™ system is designed to operate continuously in harsh environments, but filter

replacement and other maintenance measures need to be implemented as described in this section

to avoid preventable wear or damage to the system.

5.1 Recommended BoilerSpection Maintenance Schedule

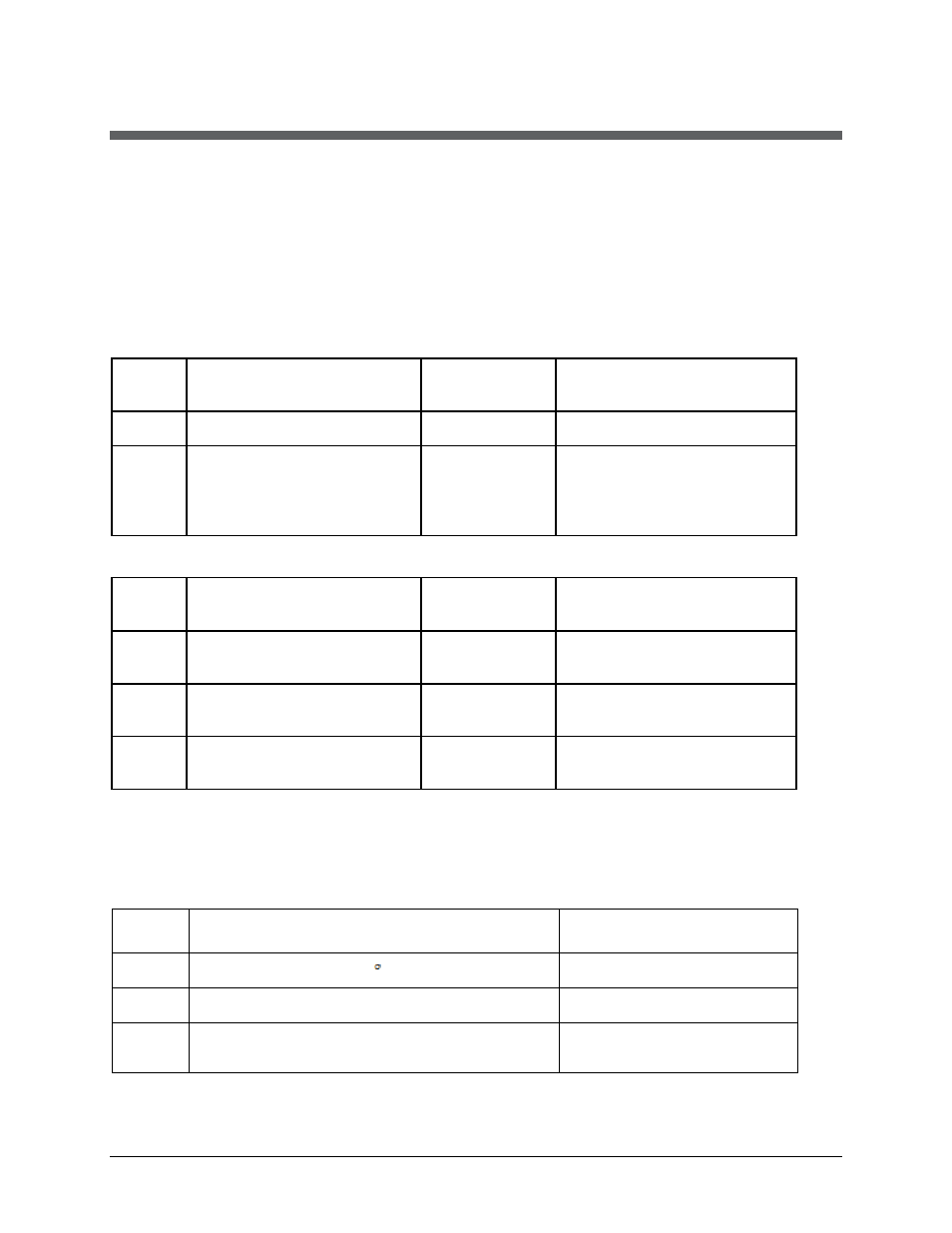

5.1.1 Inspection and Test

Item Description

Tools or Parts

Required

Maintenance Interval

1

Check all cooling systems

After each use

2

Check

air

filters

Depends on usage, but check

monthly if used regularly and

replace annually or sooner as

required

5.1.2 Preventive Maintenance

Item Description

Tools or Parts

Required

Maintenance Interval

1

Clean

lens

tip

Kimtech wipes,

Q-tip

Check when image quality

degrades

2

Replace 3 µm 1st stage air

filter, if necessary

Adjustable

wrench

Yearly or as required

3

Replace 0.3 µm 2nd stage air

filter, if necessary

Adjustable

wrench

Yearly or as required

5.2 Spare Parts

The BoilerSpection™ system is designed to operate continuously in harsh environments; however it

is recommended that spare parts be kept in storage in the event of a component failure.

We recommend that you keep the following spare components on-hand:

Item

Description

LumaSense Part Number

1

Replacement lens tip, 50 FOV

112-0051-01

2

Replacement lens tip, 75° FOV

112-0052-01

3

Additional or Spare Lens, 18" (46 cm) straight,

standard 50° HFOV

812-0046-21