Condec UPC5110 User Manual

Page 22

Maintenance and Service

19

4.2.8

ORION-2D Manifold - Panel Installation

Tools required:

7/16" open end wrench

Phillips screwdriver

hex wrench (.061")

snoop, liquid leak gas detector (PN 64781)

11/32" open end wrench (thin)

1. If not already done, remove the panel knobs from the

COARSE

(pressure),

VERNIER

, and

VENT

valves

using the .061" hex wrench.

2. Install the manifold with the transducer port side facing the panel bottom. Install the two mounting

screws (PN 60837) from the panel front and tighten until snug.

NOTE: Some manufactured units may have the vacuum generator mounted to the ORION-2D manifold body. If so, install

the muffler, coupling and long nipple assembly into the vacuum generator.

3. Install the

VERNIER

knob (17) onto the

VERNIER

valve shaft (14). Align the set screws (25) with the

indentations on the vernier valve shaft and tighten until snug using the .061" hex wrench.

4. To install and adjust the

COARSE

(pressure) and

VENT

valve knobs, follow the procedure in

Section 4.2.9.

5. Install the transducer into the manifold port, tighten with the 11/32" thin wrench and reconnect its wire

connector.

NOTE:

If transducer is hard-wired, connect the four wires to the terminal block TB1 on the CPU board per Table 4-2.

6. Install the flexible tubing going to the transducer port. Also the flexible tubing coming from the vacuum

generator, compressed air port, and the mode select assembly.

7. Install the tubing section from the

VENT

outlet fitting on the ORION-2D, using a 7/16" wrench.

8. Fill the cylinder to approximately 1000 PSIG and check all fittings for leaks. If there are no leaks, fill

nitrogen supply cylinder to maximum pressure. See Section 2.1 on page 4 for cylinder refilling

procedure.

9. Install panel/chassis assembly in its enclosure as described in Table 4.2.1 on page 14.

4.2.9

ORION-2D Manifold - Valve Adjustment Procedure

Tools required:

hex wrench (.050")

hex wrench (.061")

snoop, leak gas detector (PN 64781)

NOTE:

See Table 4-6 on page 33 and Figure 4-1 on page 34 for parts information. * denotes reference to Figure 2-2 on

page 5.

1. Energize the unit and let it warm up, 10 to 15 minutes minimum. Rotate the SUPPLY SELECT valve to

the N

2

position, the

RANGE SELECT

switch to the 100 PSI range,

DISPLAY SELECT

switch and the

MODE SELECT

valve to pressure position.

2. To adjust the

COARSE

valve, go to next step. To adjust the

VENT

valve, go to step 18.

3. If not already done, remove the ORION-2D

COARSE

valve knob (3) using the .061" hex wrench

4. Using a .050" hex wrench, loosen the set screw (34) on the locknut (2) and turn the locknut clockwise to

its stop.

5. Check to see that the knob insert (4) is securely fastened to the valve shaft (11). If it is loose, tighten the

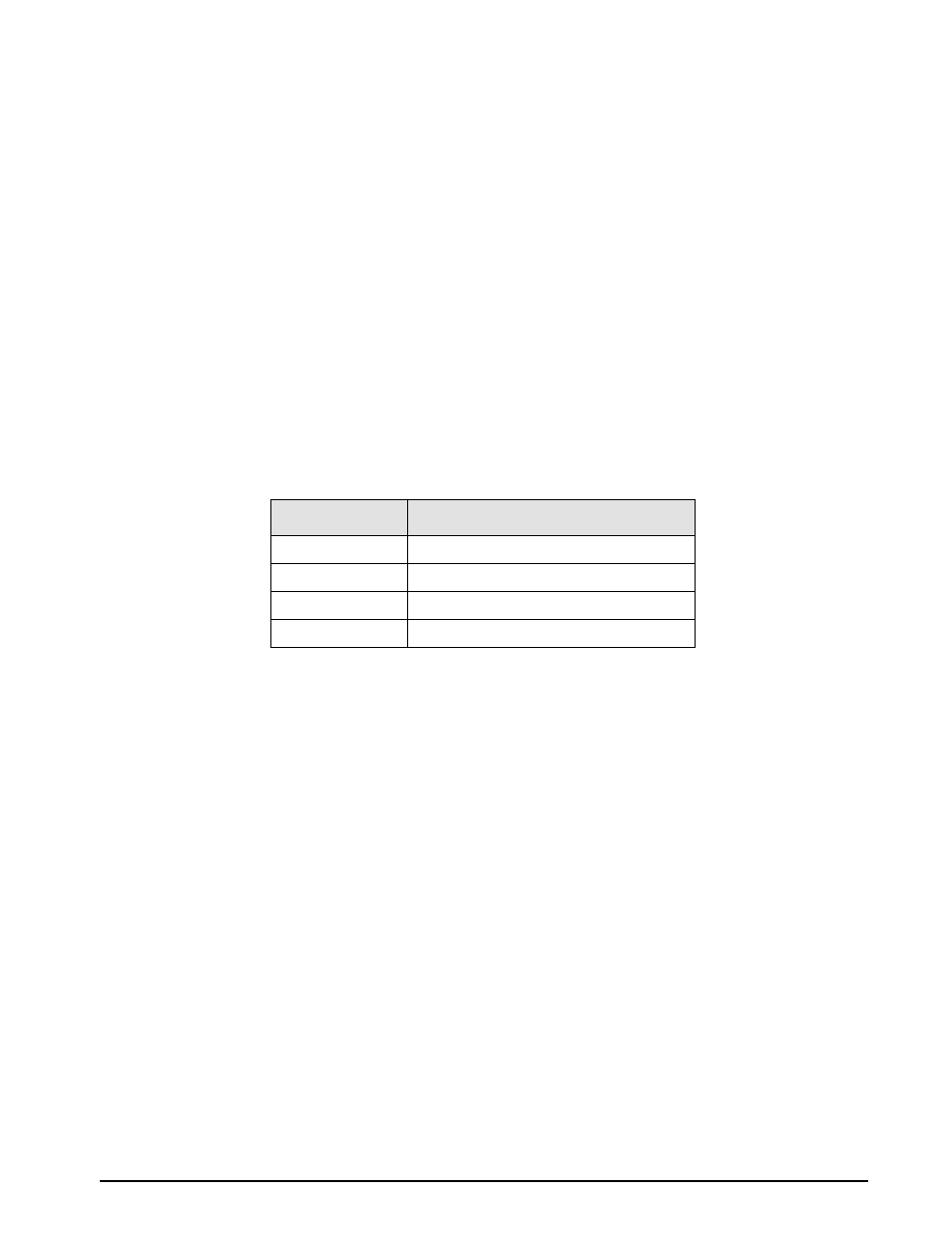

Transducer Wires

Terminal Block Wires

+ Excitation

TB1-4 (Green wire)

- Signal

TB1-6 (Red wire)

+ Signal

TB1-5 (White wire)

- Excitation

TB1-7 (Black wire)

Table 4-2. Transducer Wire to Terminal Block Wire Connections