Pro-Cut Warthog User Manual

Page 32

PG /

Ø32

800.543.6618

TIGHTENING THE GIB

Poor finish quality can be the result of a loose slide plate. As wear occurs between the slide plate and the gear box it

rides on, you must take up the slack. You do this by tightening the moveable wedge we call the “gib”

(50-463). If

the cutting head can be moved from side to side at all, it should be tightened.

To reattach the feed block, move the slide plate as far forward as it can travel, wind the feed block in to meet the plate,

and then install and tighten the two 6mm allen cap screws. This ensures that the feed block will be properly centered.

Wind the head back out and the machine is ready for use.

First loosen all five set screws (with 2mm allen wrench) by freeing the 8mm lock

nuts and loosening the allen set screw s, and remove the 2 feed block screws with

a 6 mm allen wrench.

Remove the

50-496 plate and gib completely, and clean the contact surfaces.

Locate the plate in the middle of the rail with the gib between the plate and the

rail. Be sure the 5 notches of the gib are aligned to catch the allen set screws as

they’re tightened through the plate.

Tighten each allen set screw until you feel it snug against the gib.

Hold light pressure with the allen wrench as you lock the screw down with the

8mm lock nut.

After tightening each nut, slide the plate to make sure there is no binding. When

the gib is adjusted properly, the plate will have some resistance as it slides, with

no lateral movement possible.

TO ADJUST THE GIB

(50-463):

1.

2.

3.

4.

5.

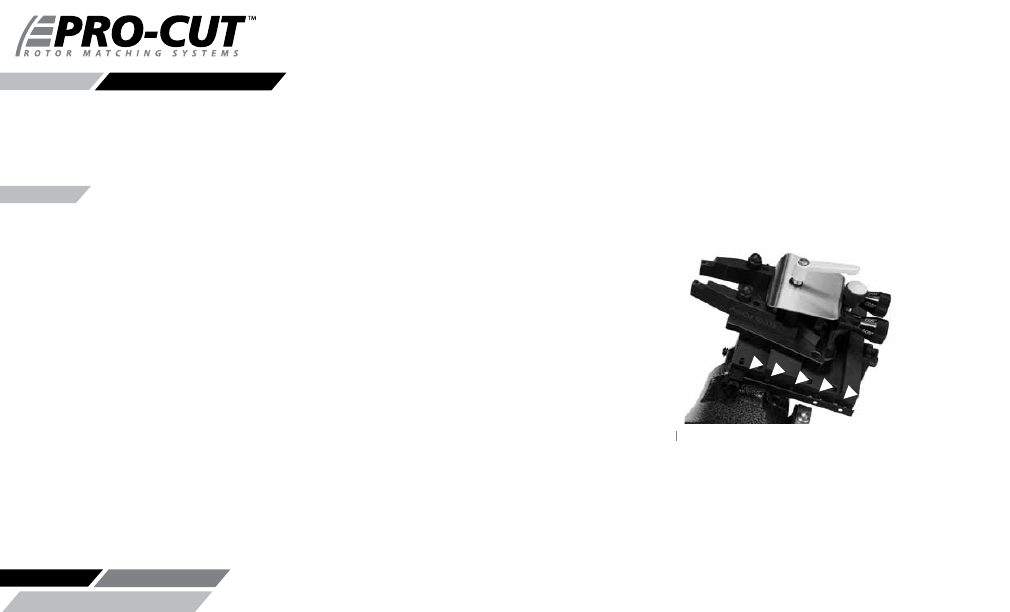

Detail of the gib adjustment screws