Inspection and maintenance, 1 routine inspection and maintenance, 2 inspection in the event of an error – Yokogawa Low Concentration (ppm) Zirconia Oxygen Analyzer OX400 User Manual

Page 54

<

7. Inspection and Maintenance>

7-1

IM 11M10B01-01E

7. Inspection and Maintenance

Routine inspection and maintenance is important to ensure operation of the OX400 in a good

condition. Perform regular inspection and maintenance in accordance with the following instructions.

7.1 Routine Inspection and Maintenance

1) Checking readings

Measure calibration gas about once every two to three months and check the readings. If an

error is found with the calibration gas concentration, perform zero-span calibration in the range

you use.

2) Checking gas flow rate

Regularly check the sensor gas flow rate in order to make sure that the flow rate is 200 ± 25

ml/min (a floater should be between upper and lower bar of the 200 ml/min bar on flowmeter.)

3) Other

Regularly check for signs of malfunction such as strange noises of the pump and fan, or

unusually high temperature of the case.

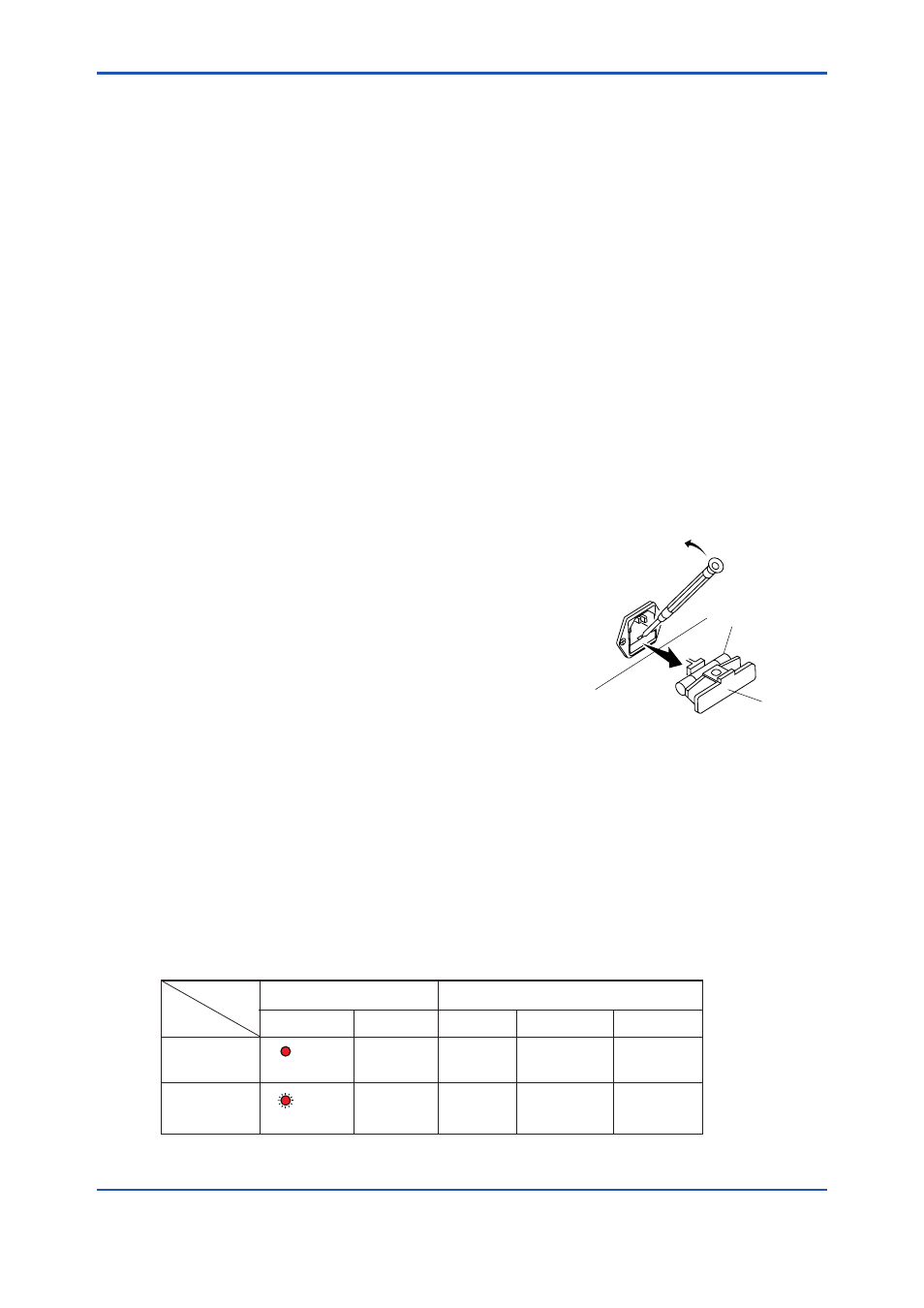

4) Replacing the fuse

Be sure to turn off the power of the OX400 and remove the

power plug from the socket before replacing the fuse. The

fuse is installed in the lower part of the power cord plug on

the rear panel of the OX400 (see right figure). Remove the

power cord from the plug, pull the fuse holder out of the

lower part of the plug, replace the fuse with a new one, and

push the fuse holder back in place. Be sure to replace the

old fuse with a correctly rated one.

If a replaced fuse burns out soon, the circuit is likely to be

defective. Please contact our service department.

7.2 Inspection in the Event of an Error

If an error occurs, the ERR/ALM lamp on the front panel turns on. An error/alarm code is displayed on

the sub-display. If multiple errors occur, codes are displayed in the order of occurrence.

An error means a malfunction, so the heater is turned off and the measurement is stopped. When

an error occurs, repair is required. On the other hand, an alarm means a warning, so measurement

is continued. An alarm occurring during calibration may invalidate the calibration depending on the

content of the alarm.

The following shows the display and output in the event of an error/alarm.

ERR/ALM

ERR/ALM

Error occurs

LED lamp

Alarm occurs

On

Flashing

Sub-display

Err code

ALM code

[ErrX]

[ALMX]

FAIL contact

DO contact

CLOSE

Closed only

in the event

of “ALM7”

OPEN

OPEN

mA output

Scale-out

by burnout

Measurement

output

Front Panel

Rear Panel

Event

Notice

(Note) When burnout function is disabled, the mA output in the event of an error (fail) is “4 mA.”

Furthermore, the mA output during warm-up is also “4 mA.”

FAIL (error) contact and DO (alarm) contact are “OPEN” when the power is OFF.

Fuse Holder

Fuse