4 sensor trim, Sensor trim -11 – Yokogawa EJX930A User Manual

Page 21

<3. Parameter Setting>

3-11

IM 01C25R05-01EN

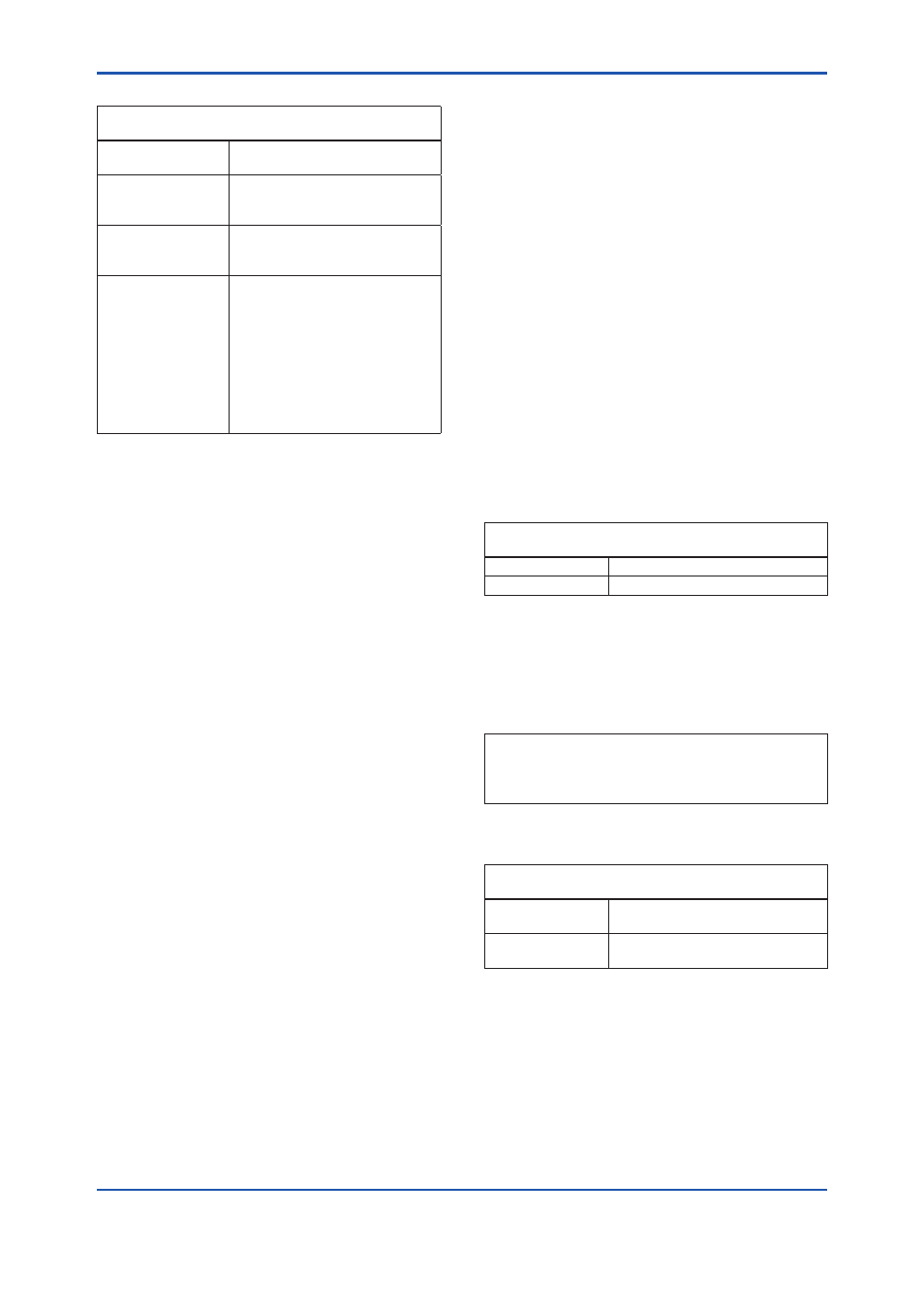

• Procedure to call up the display

[Root Menu] →Detailed setup → Display condition

→Disp User Value

→ Disp User Value

1-16

External input value (16 items)

→ Disp User Info

1_1-16_1

External input information1*

e.g. the kind of external input

value (16 items)

→ Disp User Info

1_2-16_2

External input information2*

e.g. the unit of external input

value (16 items)

→ Disp User Value

Point 1-16

The position of decimal point is

selected from the list.

• Integer

• 1 Down to 1 place of decimals

• 2 Down to 2 places of

decimals

• 3 Down to 3 places of

decimals

• 4 Down to 4 places of

decimals

*:

The characters which can be displayed are:

• Alphanumeric (upper case and lower case)

• Space

• - (minus)

• . (piriod)

• / (slash)

The displayed character length is

• 6 characters without “.” or “/”

• 7 characters if one “.” or “/” is included.

3.4.4 Sensor Trim

EJX multivariable transmitter is factory

characterized. Factory characterization is the

process of comparing a known pressure input with

the output of each transmitter sensor module over

the entire pressure and temperature operating

range. During the characterization process, this

comparison information is stored in the transmitter

EEPROM. In operation, the transmitter uses this

factory-stored curve to produce a process variable

output (PV), in engineering units, dependent on the

pressure input.

The sensor trim procedure allows you to adjust

for local conditions, changing how the transmitter

calculates process variables. There are two ways

to trim the sensor: a zero trim and a full sensor trim.

A zero trim is a one-point adjustment typically used

to compensate for mounting position effects or

zero shifts caused by static pressure. A full sensor

trim is a two-point process, in which two accurate

end-point pressures are applied (equal to or greater

than the range values), and all output is linearized

between them.

Full Sensor Trim—Auto Trim and Manual Trim

Full sensor trim is carried out by performing

Auto,

Lower Pt followed by Auto, Upper Pt.

Also, you can manually perform the trimming

procedure with

Manual, Lower Pt and Manual,

Upper Pt.

The full sensor trim is a two-point adjustment,

and the lower point adjustment should always be

performed before the upper point adjustment in

order to maintain the pitch between the zero and

100% points within the calibration range.

In the manual method, the reference pressure

should also be applied to the transmitter at both

the lower and upper points. Without the reference

pressure,

Manual, Lower Pt and Manual, Upper

Pt may not represent the correct value for each

adjustment point.

(1) Auto Sensor Trim

Applying reference pressure of 0% and 100% of the

measurement range to the transmitter, adjust the

lower and upper points automatically.

• Procedure to call up the display

[Root Menu] → Diag/Service → Calibration → Pres

sensor trim → Pres trim →

→ Auto, Lower Pt

Auto trim for 0% point

→ Auto, Upper Pt

Auto trim for 100% point

(2) Manual Sensor Trim

Using the example below, follow the steps to

perform the full sensor trim by manually. The Pres

LTD (Manual, Lower Pt) and Pres UTD (Manual,

Upper Pt) represent the previously adjusted values

Example: For the range of 1000 to 3000 mmH

2

O

Pres LTD (Manual, Lower Pt) = −4.0 mmH

2

O

Pres UTD (Manual, Upper Pt) = −3.0 mmH

2

O

<1> Call up the

Manual, Lower Pt.

• Procedure to call up the display

[Root Menu] → Diag/Service → Calibration → Pres

sensor trim → Pres trim →

→ Manual, Lower

Pt

Manual trim for 0% point

→ Manual, Upper

Pt

Manual trim for 100% point

<2> Suppose that a standard pressure of 1000

mmH

2

O is applied and the value of the “Pres

for trim” is 994.0. Correct for this output error

of 6 mmH

2

O by adding 6 mmH

2

O to

Pres LTD

(Manual, Lower Pt).

−4.0+6.0=+2.0