4 units, 5 damping time constant setup, 6 differential pressure signal low cut mode setup – Yokogawa EJX930A User Manual

Page 18: 7 impulse line connection orientation setup, Units -8, Damping time constant setup -8, Differential pressure signal low cut mode setup -8, Impulse line connection orientation setup -8

<3. Parameter Setting>

3-8

IM 01C25R05-01EN

3.3.4 Units

Refer to the subsection 3.3.3 to call up the display.

Select the unit from displayed list as shown below.

(1) Unit list of differential pressure

mmH2O, mmH2O@68degF, mmHg, Torr, MPa,

kPa , Pa, mbar , bar , gf/cm2, kgf/cm2, inH2O,

inH2O@68degF, inHg, ftH2O, ftH2O@68degF, psi,

atm, hPa

Note that the Yokogawa default setting for the

standard temperature is 4°C (39.2°F). For the units

of mmH

2

O, inH

2

O, and ftH

2

O, the pressure varies

according to the standard temperature definition.

Select the appropriate unit with @68degF when a

standard temperature of 20°C (68°F) is required.

(2) Unit list of static pressure

mmH2O, mmH2O@68degF, mmHg, Torr, MPa,

kPa , Pa, mbar , bar , gf/cm2, kgf/cm2, inH2O,

inH2O@68degF, inHg, ftH2O, ftH2O@68degF, psi,

atm, hPa

(3) Unit list of temperature

degC , degF, Kelvin

3.3.5 Damping Time Constant Setup

Any number from 0.00 to 100.00 can be set for

the amplifier damping time constant of process

variables.

Refer to subsection 3.3.3 to call up the display.

Damping time constant is set as shown in the

following table at the factory when the instrument

is shipped, but in case of the option code /CE is

specified, the damping time constant is set as

specified in the order.

Process variables

Factory default value

Differential pressure

2s

Static pressure

1s

External temperature

1s

NOTE

The damping time constant for the amplifier

assembly can be set here. The damping time

constant for the entire transmitter is the sum of

the values for the amplifier assembly and the

capsule assembly.

About the value for the capsule assembly, refer

to the User’s Manual for EJX910/EJX930

(IM 01C25R01-01E) or General Specifications

(GS 01C25R01-01EN, GS 01C25R04-01EN).

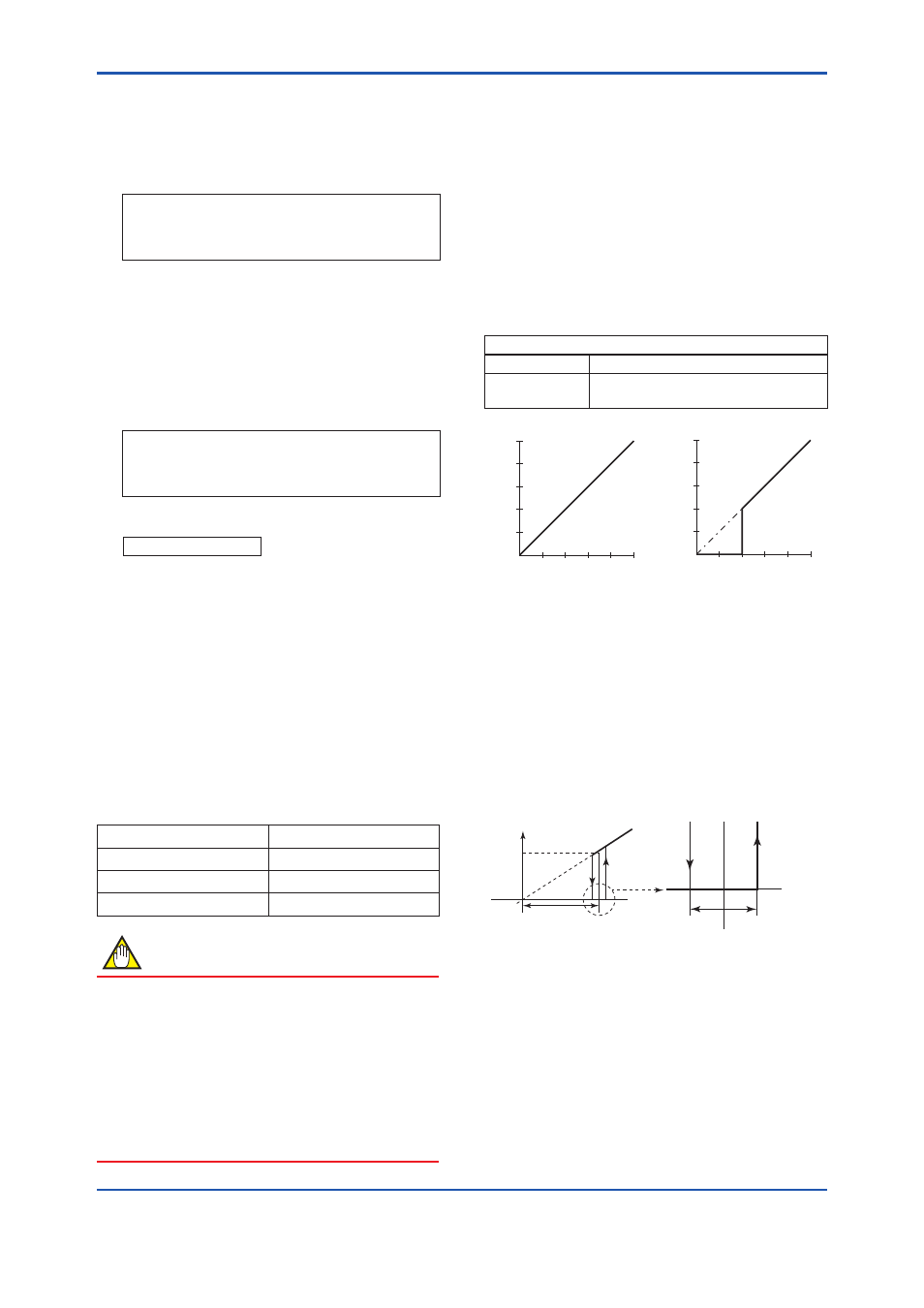

3.3.6 Differential Pressure Signal Low Cut

Mode Setup

Low cut mode can be used to stabilize the

differential pressure output signal near the zero

point. The Low cut is applied to the differential

pressure used to flow calculation. The low cut point

can be set from 0 to 20% of output. (Hysteresis for

the cut point: ±10% of the cut point )

Follow the procedure below to change the Low cut

mode and Low cut point.

• Procedure to call up the display

[Root Menu] → Basic setup → Others →

→ Low cut

Set from 0 to 20% of output

→ Low cut

mode

Select “On” or “Off”

(%)

50

(%)

50

0

50

(%)

50

(%)

DP

Output

DP

Output

For low cut in Off mode

Input

20

20

0

For low cut in On mode

Input

F0303.ai

Figure 3.2

Low Cut Mode

The low cut point has hysteresis so that the output

around the point is behaved as below figure.

Low cut mode: On

Low cut: 20.00%

F0304.ai

Setting range: 0 to 20%

2%

2%

0%

DP Output

Low cut point

Input

Hysteresis

fixed at 10%

of the cut point

20%

3.3.7 Impulse Line Connection Orientation

Setup

This function reverses the impulse line orientation.

This function is used when the high pressure side

impulse line and the low pressure side impulse line

are connected reverse by mistake.

Follow the procedure below to assign the high

pressure impulse line to the L side of the transmitter.