Series 35 serpar, Double valves with l-g monitor, Overview of valve function – Ross Controls SERPAR AND CROSSFLOW DOUBLE VALVES SERIES 35 User Manual

Page 7

www.rosscontrols.com

7

A

B

1

3

2

S

Pb

Pa

A

B

1

3

2

C D

S

Pb

Pa

A

B

1

3

2

C D

S

Pb

Pa

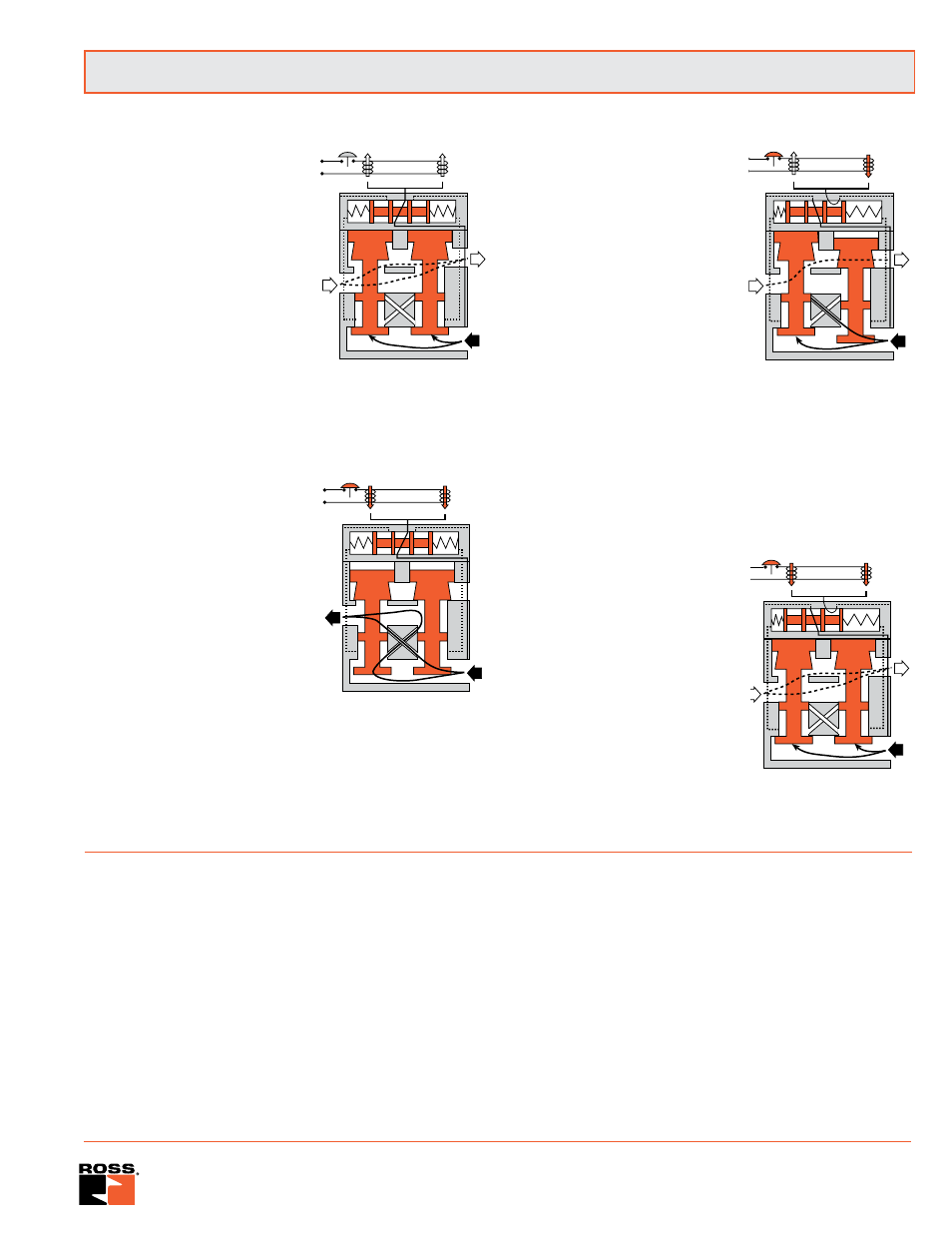

Conditions at start:

Normal operation:

Detecting a malfunction:

Conditions at start:

Inlet 1 is closed to outlet 2 by both

valve elements A and B. Outlet 2

is open to exhaust 3. Pilot air is

ported from inlet 1 and through

the center section of spool S to the

normally closed pilots Pa and Pb.

Monitoring pressure signals at both

ends of spool S are exhausted.

Normal operation:

Simultaneously energizing both

solenoids actuates both pilots and

causes valve elements A and B to

shift. Inlet 1 is then connected to

outlet 2 via crossflow passages

C and D. Exhaust 3 is closed.

Monitoring pressure signals go to

each end of spool S and become

equal to inlet pressure.

Completition of normal cycle:

Simultaneously deenergizing both

solenoids returns the valve to the

“Conditions at Start” described at

left.

Detecting a malfunction:

A malfunction in the system or

the valve itself could cause one

valve element to be open and the

other closed. Air then flows past

the inlet poppet on valve element

A, into crossflow passage D, but is

substantially blocked by the spool

portion of element B. The large size

of the open exhaust passage past

element B keeps the pressure at

the outlet port below two percent of

inlet pressure. Full monitoring air

pressure from side A goes to the

right end of spool S, and a reduced

pressure goes to the left end. This

pressure imbalance causes the spool

to shift to the left. This shuts off and

exhausts pilot air to both solenoid

pilots, and allows valve element A to

return to the closed position.

L-G monitor locked-out:

When the L-G spool shifts it is held

by a lockout pin (not shown). Pilot

air is then exhausted to atmosphere

via port YB, and pilot supply air is

diverted to atmosphere via port YA.

The lockout mechanism must be reset

before the valve can return to normal

operation. During and following reset,

the pilot solenoids must be kept

deenergized to prevent inadvertent

and possibly dangerous cycling

of the press. The reset function is

either manual or remote-pneumatic

depending on valve model.

A

B

1

3

2

S

Pb

Pa

YA

YB

L-G monitor locked-out:

Series 35 SERPAR

®

Double Valves with

L-G

Monitor

Overview of Valve Function

For accessories please see page 17.

Double Valves with Internal Monitoring & Lockout feature:

Internal monitoring – requires no additional monitoring circuitry

•

Automatic lock-out/inhibit upon detection of a malfunction

•

Default to de-energized position upon fault detection

•

Dedicated reset function

•

No undesired automatic reset upon removal of electrical or pneumatic energy sources

•

Built-in non-clogging silencers on Sizes 4, 8, 12 and 30.

•