Overview of serpar and crossflow function, Serpar, And crossflow – Ross Controls SERPAR AND CROSSFLOW DOUBLE VALVES SERIES 35 User Manual

Page 4: Double valves, Overview of serpar, Functions

4

ROSS CONTROLS

®

SERPAR

®

and Crossflow

TM

Double Valves

The design of the SERPAR

®

and Crossflow

TM

double valve is distinguished by

crossflow passages and spool valving on the main valve stems. This arrangement

provides the valve’s unique flow characteristics.

Monitors: Self-contained monitors, designed to inhibit valve operation in case of

a fault within the valve, are built into the valve assembly. There are three types of

ROSS monitors available: pneumatic, electro-pneumatic, and electronic.

Valve Sizes: ROSS double valves are available in four sizes. For convenience, valves

are designated by the nominal sizes 4, 8, 12, and 30. These sizes approximate

an average of the flow coefficients (C

V

) of the various flow paths through the valve.

Further information about C

V

ratings is given on page 14.

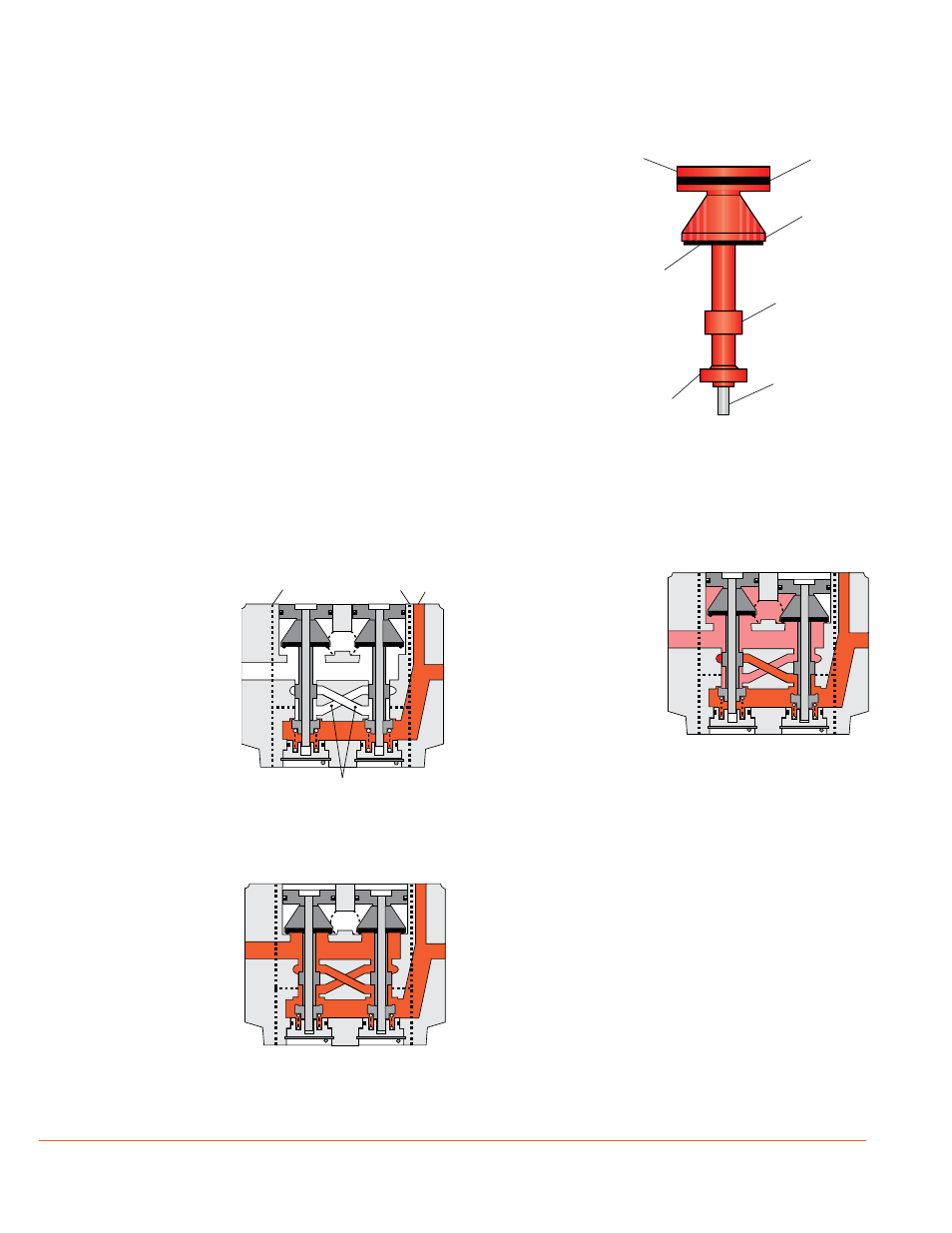

Valve Element Construction: The dual valve elements are of lightweight

construction. Their low inertia allows them to respond quickly to actuating and

deactuating forces. Impact loads are also kept small to help assure long valve life.

Each valve element is guided at the top by the piston and at the bottom by the

stainless steel stem, and there is no sliding bearing surface between.

Buna N Lip Seal

Delrin Piston

Buna N

Poppet Seal

Delrin Poppet

Support

Delrin Spool

Polyurethane

Inlet Poppet

Stainless Steel

Stem

Air flow paths:

Parallel flow paths develop

equal forces on the valve

elements in both the actuated

and deactuated modes. This

enables both valve elements

to respond equally to pilot

pressures and promotes

synchronous movement of

the valve elements. The air

flow paths for the valve in

different operating modes are

shown below.

Valve elements

de-actuated:

With both inlet poppets

closed, inlet air pressure

holds each poppet firmly

against its seat. Exhaust

poppets are open to an

oversized exhaust por t,

and monitoring air pressure

signals are zero. Monitoring

air passages (shown as

dashed lines) go upward or

downward depending on the

location of the monitoring

device being used.

Valve elements actuated:

With the valve elements

in the actuated position,

inlet air is free to flow past

the two inlet poppets and

through the two crossflow

passages to the outlet port.

The exhaust poppets close

off the exhaust port, and

monitoring pressure signals

become equal to inlet pressure.

When the valve is returned to the deactuated position (see figure

at top of this page), the design of the spool elements (on the valve

stem) allows any pressure remaining in the monitoring or crossflow

passages to be exhausted through the open exhaust port.

Detecting a malfunction:

A malfunction in the system or in the valve itself could cause one

valve element to be open and the other closed. In this event inlet

air from the open inlet poppet is substantially blocked from the

outlet port by the spool on the closed valve element. The large

size of the open exhaust passage serves to keep the pressure

at the outlet port below two percent of the inlet pressure.

The monitoring pressure signal from the open valve element is

equal to inlet pressure, while the monitoring signal from the closed

valve element is very small. The monitor senses the difference

between these two pressures and uses this information to shut

down the valve and inhibit further valve action. After the cause

of the malfunction has been corrected and the electrical signal

has been removed from the pilot solenoid, the monitor can be

reset and normal operation can be resumed.

OUT

IN

EXH

Crossflow Passages

Monitoring Air Passages

Pilot Air

Passage

OUT

IN

EXH

OUT

IN

EXH

Overview of SERPAR

®

and Crossflow

TM

Functions