Series 35 crossflow, Double valves with pressure switches, Overview of valve function – Ross Controls SERPAR AND CROSSFLOW DOUBLE VALVES SERIES 35 User Manual

Page 16: Ab 1 3 2

16

ROSS CONTROLS

®

Series 35 Crossflow

TM

Double Valves with

Pressure Switches*

A

B

1

3

2

Pb

Pa

SWB

1

4

2

SWA

1

4

2

*NOTE: These models have two pressure switches that sense pressure in the sensing ports resulting from the movement of

corresponding valve elements. The pressure switches only indicate if the valve elements do not move in unison.

The switches will not lock out the valve without the addition of an external monitoring system and should not be confused with a

monitor. If lock-out capability is advisable for your application, be sure to connect the pressure switches to an external monitor.

If an internal monitor is preferred, use a model with LG, EP, or DS monitor.

These models are also available with:

1) no pressure switches installed, but with provision for installing pressure switches later, or

2) with no switches installed and no provision for installing them later.

The models with no provision for pressure switches are not capable of being monitored and should not be used in applications

where lock-out capability is a requirement, i.e. press clutch/brakes.

SWITCH OPERATION: Each pressure switch has four electrical contacts. Contacts 1 and 2 are connected when no air pressure

signal is applied to the switch. Contacts 1 and 4 are connected when an air pressure signal is applied to the switch. Contact 3

is for a ground connection.

For further information in the use or connection of the pressure switches call your local ROSS distributor or, in the U.S.A., call ROSS Technical

Services at 1-888-TEK-ROSS.

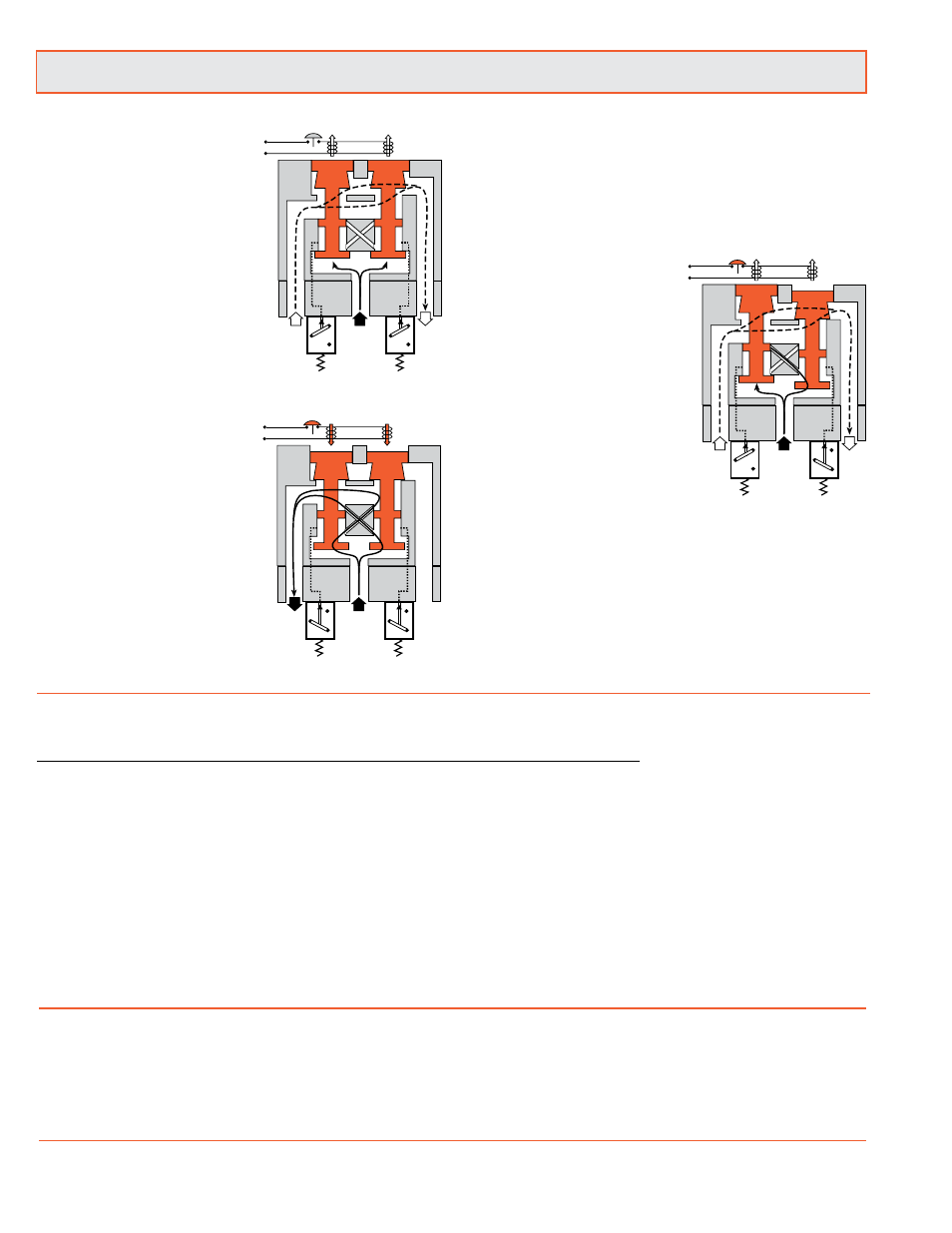

Conditions at start:

Inlet 1 is closed to outlet 2 by both

valve elements A and B. Outlet

2 is open to exhaust 3. Pressure

signals at both switches SWA and

SWB are exhausted. Contacts 1

and 2 of switches SWA and SWB

are connected.

Normal operation:

Simultaneously energizing both

solenoids actuates both pilots and

causes valve elements A and B

to shift. Inlet 1 is then connected

to outlet 2 via crossflow passages

C and D. Exhaust 3 is closed.

Sensing pressure signals go to

each pressure switch and become

equal to inlet pressure. Both

switches trip and now contacts 1

and 4 of switches SWA and SWB

are connected instead of contacts

1 and 2.

Completition of normal cycle:

Simultaneously de-energizing

both solenoids returns the valve

and switches to the “Conditions

at Start” described above.

Detecting a malfunction:

A malfunction in the system or

the valve itself could cause one

valve element to be open and the

other closed. Air then flows past

the inlet poppet on valve element

A, into crossflow passage D, but

is substantially blocked by the

spool portion of element B. The

large size of the open exhaust

passage past element B keeps

the pressure at the outlet port

below 2 % of inlet pressure. Full

sensing air pressure from side

A goes to switch SWA, and a

reduced pressure goes to switch

SWB. This full pressure signal

causes switch SWA to trip. Switch

SWB, with a reduced pressure

signal, does not trip. An external

monitoring system can detect

the malfunction by monitoring

the condition of the switches

SWA and SWB. The external

monitoring system may then react

accordingly by shutting down the

power to the valve solenoids and

any other components deemed

necessary to stop the machine.

See note below.

A

B

1

3

2

Pb

Pa

2

SWA

1

4

2

SWB

1

4

C D

A

B

1

3

2

Pb

Pa

2

C D

SWB

1

4

SWA

1

4

2

Conditions at start:

Normal operation:

Detecting a malfunction:

Double Valves with Pressure Switches for External Monitoring feature:

Designed to enable users to comply with current safety regulations

•

Can be integrated with external monitoring systems to provide for lockout and inhibiting further machine operation until the

•

controls system is reset

Default to de-energized position upon fault condition

•

Built-in non-clogging silencers on Sizes 4, 8, 12 and 30.

•

Overview of Valve Function