Valve response time and cv ratings, General information – Ross Controls SERPAR AND CROSSFLOW DOUBLE VALVES SERIES 35 User Manual

Page 18

18

ROSS CONTROLS

®

VALVE RESPONSE TIMES

Most pneumatic applications call for a valve to be used to control

the repeated filling and exhausting device (cylinder, clutch, etc.)

having a certain volume. The time required to fill or exhaust this

volume is called the “valve response time.”

The time to fill a volume is usually different from the time to

exhaust the volume. However, both times can be found using

the following formula:

Valve Response Time (msec) = M + F • V

This formula will give the number of milliseconds (msec) required

to fill the volume V to 90 percent of supply pressure or to

exhaust the volume to 10 percent of supply pressure. M and

F are average response constants, and their values for each

valve are given on the valve specification pages (6-12). V is the

number of cubic inches in the volume to be filled or exhausted.

Response times will be valid for any supply pressure from 3.5

to 8.5 bar (50 to 125 psig).

What is the constant M? When a valve is energized, it takes a

number of milliseconds for the valve to shift and allow a steady

flow of air to be established at the outlet port. In a like manner,

when the valve is deenergized, it takes a number of milliseconds

for the valve to cut off the flow of air and establish the flow of

exhaust air. These valve “movement” times are designated by

M in the above formula.

What is the constant F? After the valve has shifted and air

flow (either to fill or exhaust) is established, the air flows rapidly

at first, then flows at a reducing rate. The average flow rate is

represented in the above formula by the letter F. It is the average

number of milliseconds required to fill or exhaust one cubic inch

of the volume V. The product F • V, then, is the average number

of milliseconds required to fill or exhaust the entire volume V

after the valve has shifted.

SAMPLE PROBLEM.

How long will it take to fill a 100-cubic-inch clutch to 90 percent

of supply pressure using a nominal size 8 double valve with

3/4 ports?

Solution. Specifications for size 8 valves are given on pages 8,

10, and 12. From the chart on page 8 (pages 10 and 12 will give

the same values) we find that the average response constants

for a size 8 valve with 3/4 ports are M = 15 and F = 0.65. The

F value of 0.23 is for the exhausting paths and is not needed

for this problem. Putting the M and F values into the response

time formula gives:

Average response time = 15 + (0.65)(100)

= 15 + 65

= 80 msec

Therefore, the 100-cubic-inch volume would be filled to 90

percent of supply pressure in just 80 milliseconds.

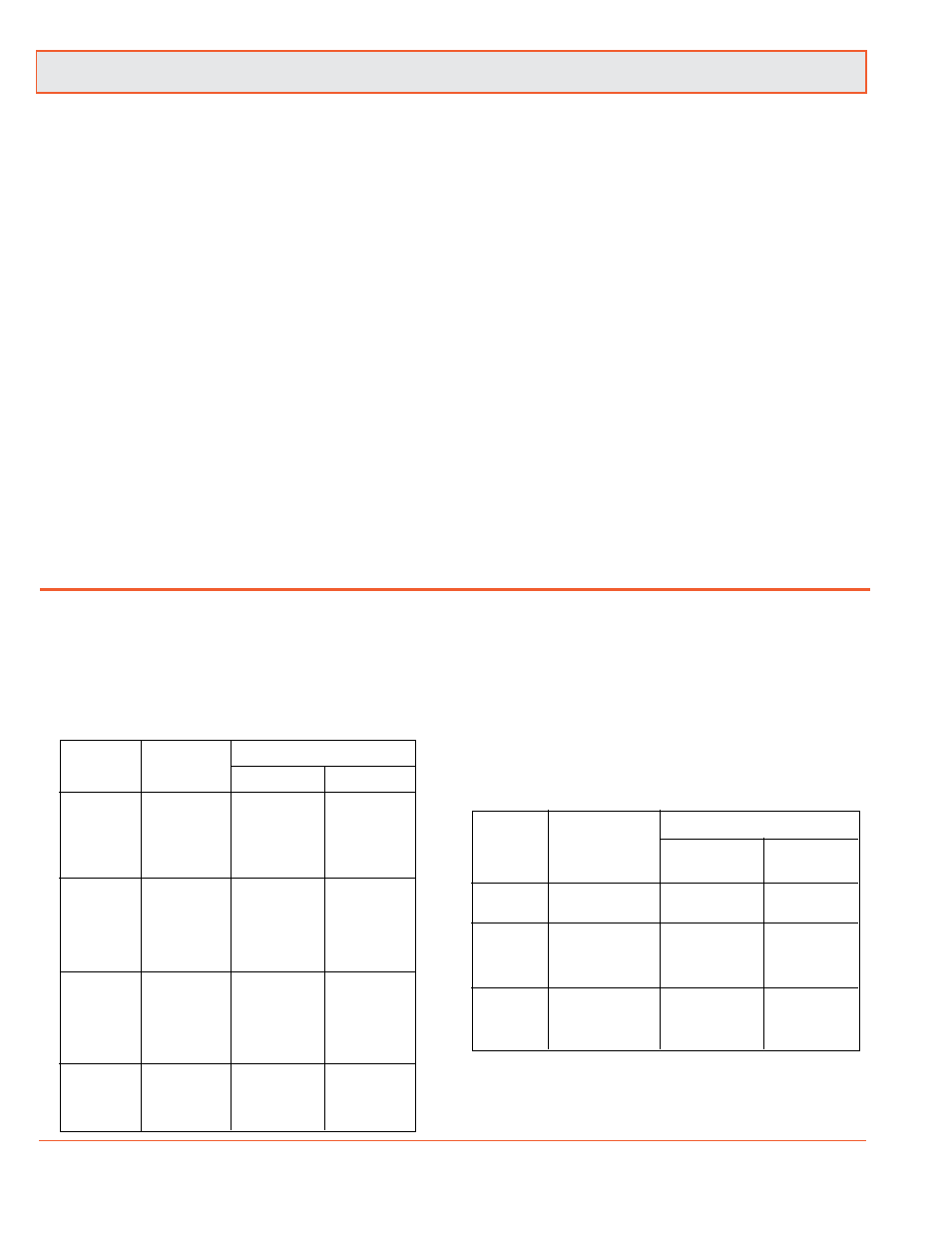

AVERAGE C

V

RATINGS

Because widely differing test standards are used in the

measurement of C

V

values, the following figures should not

be used in comparing ROSS valves with other makes. These

C

V

ratings are intended only for use with performance charts

published by ROSS.

THREAD OPTIONS

To serve customers around the world, ROSS supplies double

valves with threaded pressure ports and electrical openings

that conform to various local standards. These variations are

identified by a letter preceding the valve model number or flange

kit number. The specifications for these prefix letters are shown

in the chart at the right.

None

D

J

NPT

DIN 259

(parallel)

DIN 259

(parallel)

1/2 NPSC

R 1/2

R 1/2

3/4 NPSC

R 3/4

R 3/4

Electrical Opening

Prefix

Letter

Pneumatic

Port

Threads

L-G or E-P

Monitor

D-S

Monitor

General Information

4

8

12

30

3/8

1/2

3/4

1/2

3/4

1

3/4

1

11/4

11/4

11/2

3.0

3.0

3.0

3.5

4.0

4.0

8.0

8.5

9.0

20

21

7

9

11

10

14

14

15

19

21

42

43

Average C

V

Ratings

Nominal

Size

Port

Size

1 to 2

2 to 3