Series 35 serpar, Double valves with d-s monitor, Overview of valve function – Ross Controls SERPAR AND CROSSFLOW DOUBLE VALVES SERIES 35 User Manual

Page 11

www.rosscontrols.com

11

STANDARD SPECIFICATIONS: For valves on this page.

Pilot Solenoids: Two, rated for continuous duty.

Standard voltages: 100-110 volts, 50 Hz; 100-120 volts, 60 Hz;

24 volts DC; 110 volts DC. Uses same voltage and frequency

as pilot solenoids, but power supply must be independent and

continuous.

Power Consumption: Each solenoid, 87 VA inrush, 30 VA holding

on 50 or 60 Hz; 14 watts on DC.

Ambient Temperature: 40° to 120°F (4° to 50°C).

Media Temperature: 40° to 175°F (4° to 80°C).

Flow Media: Filtered air; 5 micron recommended.

Pressure Range: 30 to 125 psig (2 to 8.5 bar).

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.

A

B

1

3

2

C D

Ib Ia

COMPARATOR

and CONTROL

CIRCUITS

SWb

SWa

Sb

Sa

Pb

Pa

A

B

1

3

2

Pb

Pa

Ib Ia

COMPARATOR

and CONTROL

CIRCUITS

SWb

SWa

Sb

Sa

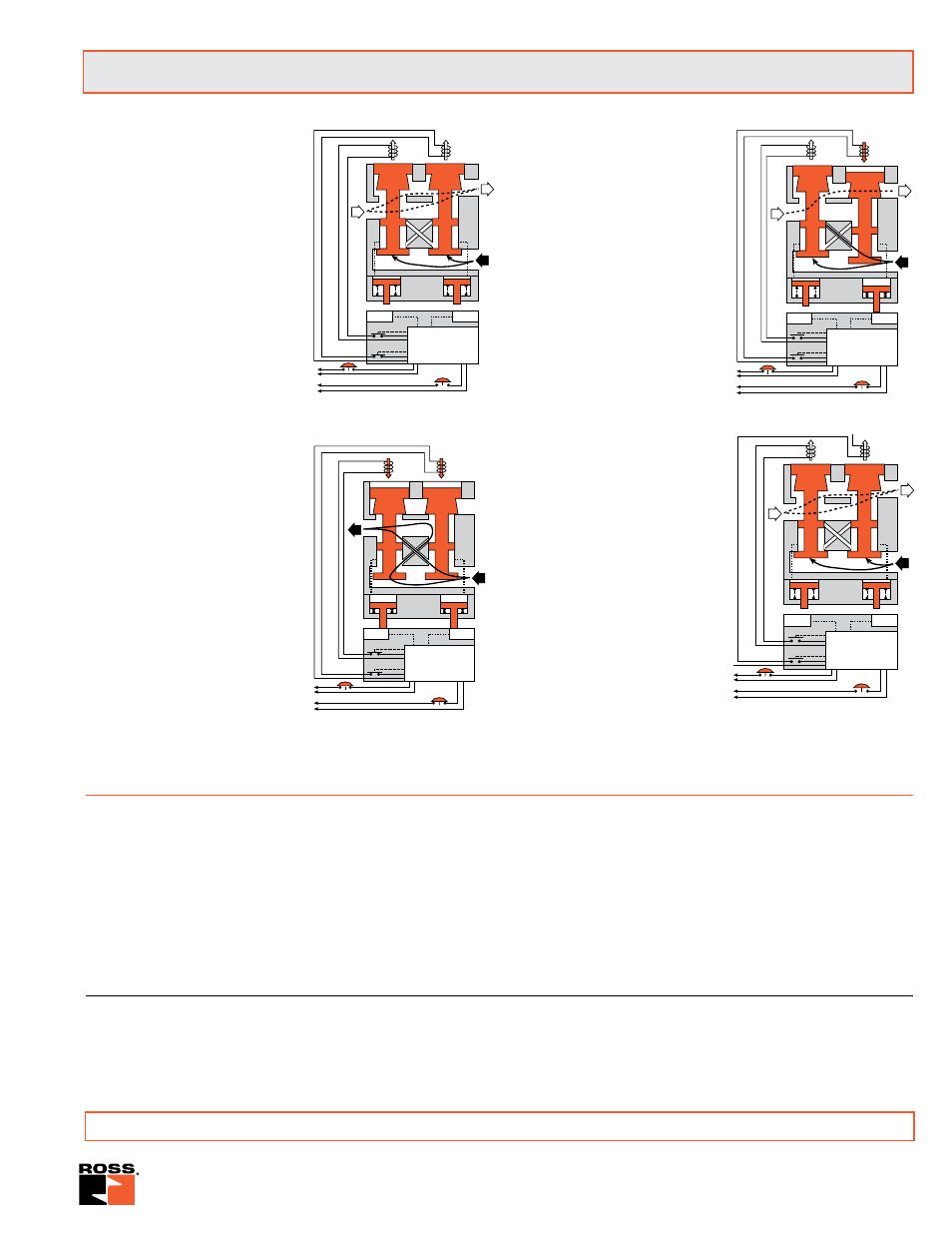

Conditions at start:

Inlet 1 is closed to outlet 2 by both

valve elements A and B. Outlet 2

is open to exhaust 3. Contacts of

switch SW are closed. Monitoring

pressure signals at both ends of

spool S are exhausted.

Normal operation:

Simultaneously energizing both

solenoids actuates both pilots and

causes valve elements A and B to

shift. Inlet 1 is then connected to

outlet 2 via crossflow passages

C and D. Exhaust 3 is closed.

Monitoring pressure signals go

to pressure indicators Ia and

Ib, causing the indicator pins

to be extended and to actuate

proximity switches SWa and

SWb. In normal operation, each

pair - solenoids, valve elements,

indicators, and proximity switches

- responds in unison so that the

comparator circuits “read” the

operation as normal.

Completition of normal cycle:

Simultaneously deenergizing both

solenoids returns the valve to the

“Conditions at Start” described

at left.

Detecting a malfunction:

A malfunction in the system or the

valve itself could cause one valve

element to be open and the other

closed. Air then flows past the

inlet poppet on valve element A,

into crossflow passage D, but is

substantially blocked by the spool

portion of element B. The large

size of the open exhaust passage

past element B keeps the pressure

at the outlet port below two percent

of inlet pressure. Full monitoring

air pressure from side A goes

to pressure indicator Ia so that

its pin is extended and actuates

proximity switch SWa. When

the time interval between the

signal to a solenoid and the signal

from its corresponding proximity

switch exceeds approximately

175 milliseconds, the D-S monitor

breaks contacts Sa and Sb as soon

as solenoid power is removed. This

allows valve element A to return to

the closed position.

D-S monitor locked-out:

With the valve locked out by

contacts Sa and Sb, solenoids

Pa and Pb cannot be energized.

The monitor must be reset before

another valve cycle can begin.

Reset can be achieved by a

separately connected ancillary

switch, but not if the pilot solenoids

are energized. The monitor can be

reset by removing and reapplying

power to the monitor even when the

pilot solenoids are energized. For

this reason it is necessary to have

the pilot solenoids deenergized

during and following reset to

prevent inadvertent and possibly

dangerous cycling of the press.

A

B

1

3

2

Pb

Pa

Ib Ia

COMPARATOR

and CONTROL

CIRCUITS

SWb

SWa

Sb

Sa

A

B

1

3

2

C D

Ib Ia

COMPARATOR

and CONTROL

CIRCUITS

SWb

SWa

Sb

Sa

Pb

Pa

Series 35 SERPAR

®

Double Valves with

D-S

Monitor

Conditions at start:

Normal operation:

Detecting a malfunction:

D-S monitor locked-out:

Overview of Valve Function

For accessories please see page 17.

D-S Monitor Double Valves include a self-contained, dynamic, electronic monitor that checks for proper valve operation

during each cycle. Allowable discordance between each internal element is fixed at 175ms and is non-adjustable. A separate

monitor power supply is wired into the terminal strip and must be constant, i.e. non-interruptible. Valve monitor faults, when

detected, are not revealed until the valve cycle is complete, e.g. the valve is de-energized, allowing for completion of the

current press stroke. Monitor reset must include a

dry contact

wired into terminals G and H to properly reset the valve.

Applying power to the reset terminals will result in monitor damage.