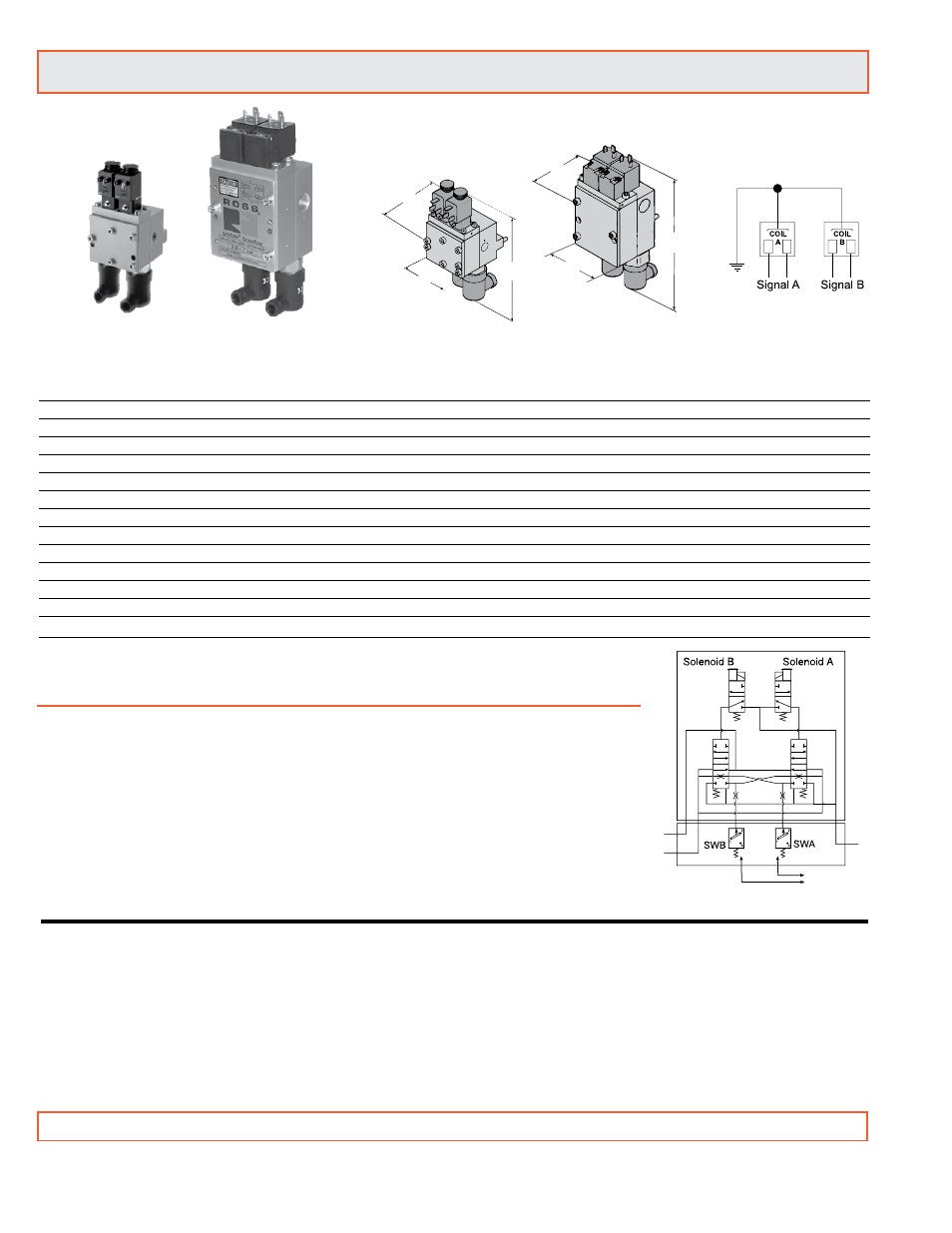

Series 35 crossflow, Double valves with pressure switches, Size 1 & 2 – Ross Controls SERPAR AND CROSSFLOW DOUBLE VALVES SERIES 35 User Manual

Page 12

12

ROSS CONTROLS

®

3

2

1

Valve Assembly

Avg. Response Constants

Valve Model

Avg. C

V

Pressure Press. Switch Port Sizes Dimensions inches (mm)

F

Weight

Size Number*

1-2 2-3

Switches** Provision 1 & 2 3

A

B

C

M In-Out Out-Exh. lb (kg)

1 3573B2632 0.9 1.4

None

Yes

1/4 1/4

2.7 (69) 3.3 (84) 5.0 (127) 28

4.6

3.4

2.1 (95)

1 3573B2640 0.9 1.4

None

No

1/4 3/8

2.7 (69) 3.3 (84) 5.0 (127) 24

4.4

3.1

2.1 (95)

1 3573B2642 0.9 1.4

Two

Yes

1/4 1/4

2.7 (69) 3.3 (84) 7.5 (191) 28

4.6

3.4

2.5 (1.14)

1 3573B2644 1.2 1.7

Two

Yes

3/8 3/8

2.7 (69) 3.3 (84) 7.6 (195) 25

3.1

2.8

2.9 (1.32)

1 3573B2645 1.2 1.7

None

Yes

3/8 3/8

2.7 (69) 3.3 (84) 5.1 (130) 25

3.1

2.8

2.5 (1.14)

2 3573B4620 3.7 6.6

None

No

1/2 1/2

3.4 (86) 3.2 (81) 6.3 (160) 30

1.2

1.0

4.3 (1.95)

2 3573B4632 3.7 6.6

None

Yes

1/2 1/2

3.4 (86) 3.2 (81) 6.5 (165) 30

1.2

1.0

4.3 (1.95)

2 3573B4640 3.7 9.0

None

No

1/2 3/4

3.4 (86) 3.2 (81) 6.5 (165) 25

1.1

0.9

4.3 (1.95)

2 3573B4642 3.7 6.6

Two

Yes

1/2 1/2

3.4 (86) 3.2 (81) 9.0 (229) 30

1.2

1.0

4.8 (2.18)

2 3573B4643 4.2 9.0

None

No

3/4 3/4

3.4 (86) 3.2 (81) 6.5 (165) 25

1.1

0.9

4.7 (2.13)

2 3573B4644 4.2 9.0

Two

Yes

3/4 3/4

3.4 (86) 3.2 (81) 9.0 (165) 25

1.1

0.9

5.2 (2.36)

2 3573B4645 4.2 9.0

None

Yes

3/4 3/4

3.4 (86) 3.2 (81) 6.5 (165) 25

1.1

0.9

4.7 (2.13)

2 3573B4652 3.7 9.0

None

Yes

1/2 3/4

3.4 (86) 3.2 (81) 9.0 (165) 25

1.1

0.9

4.3 (1.95)

* Model number includes base. For BSPP threads, order with a “D” prefix. For JIS threads, order with a “J” prefix.

Valve and base can be ordered separately; consult ROSS.

** Only valves with pressure switches should be used to control clutch/brake mechanisms on press machinery.

The pressure switches must be used in conjunction with a monitoring device to assist with OSHA compliance (Ref. 1910.217).

B

C

A

Crossflow

TM

Size 1

Crossflow

TM

Size 2

B

A

C

*Pressure Switches & Monitoring:

Valves without pressure switches must not

be used to control clutch/brake mechanisms

on press machinery. Valves with pressure

switches must be used in conjunction with an

external monitoring device to assist with OSHA

compliance (Ref. 1910.217).

The valves on this page do not have a built-in

monitor, and must only be used in conjunction

with an external monitoring system. Such

monitoring system must be capable of inhibiting

the operation of the valve in the event of a

failure within the valve.

* Non-monitored

Size 1 & 2

To customer’s external monitor

Series 35 Crossflow

TM

Double Valves with

Pressure Switches*

Valve Response Time (msec) = M + F • V

See page 18 for response time values.

STANDARD SPECIFICATIONS: For valves on this page.

Pilot Solenoids: Two, rated for continuous duty.

Standard Voltages: 100-110 volts, 50 Hz; 100-120 volts, 60 Hz;

24 volts DC; 110 volts DC. For other voltages, consult ROSS.

Power Consumption:

Size 1: Each solenoid, 12 VA maximum inrush, 9.8 VA maximum

holding on 50 or 60 Hz; 7.5 watts nominal on DC.

Size 2: Each solenoid, 8.5 VA maximum inrush, 8.5 VA maximum

holding on 50 or 60 Hz; 6 watts maximum on DC.

Electrical Connections: Uses two cord-grip connectors at solenoids

(order separately).

Size 1: DIN 43650 Form B connector P/N 266K77.

Size 2: Din 43650 Form A connector P/N 937K87.

Ambient Temperature: 40° to 120°F (4° to 50°C).

Media Temperature: 40° to 175°F (4° to 80°C).

Flow Media: Filtered air; 5 micron recommended.

Inlet Pressure: 40 to 100 psig (2.8 to 7 bar).

CAUTION: If the system must be reset, electrical signals to both

solenoids must be removed to prevent the machine from immediately

recycling and producing a potentially hazardous condition.

IMPORTANT NOTE: Please read carefully and thoroughly all of the CAUTIONS on the inside back cover.