Lincoln Electric LTW2 LEARNING TO STICK WELD User Manual

Page 9

6

LEARNING TO STICK WELD

Overhead Welding

Various techniques are used for overhead welding. However, in the

interest of simplicity for the inexperienced welder the following

technique will probably take care of most needs for overhead welding:

1. Use 1/8" (3.2mm) at 90-105 amps or 3/32" (2.4mm) at 60 amps

Fleetweld

®

180 electrode.

2. Put the electrode in the holder so it sticks straight out.

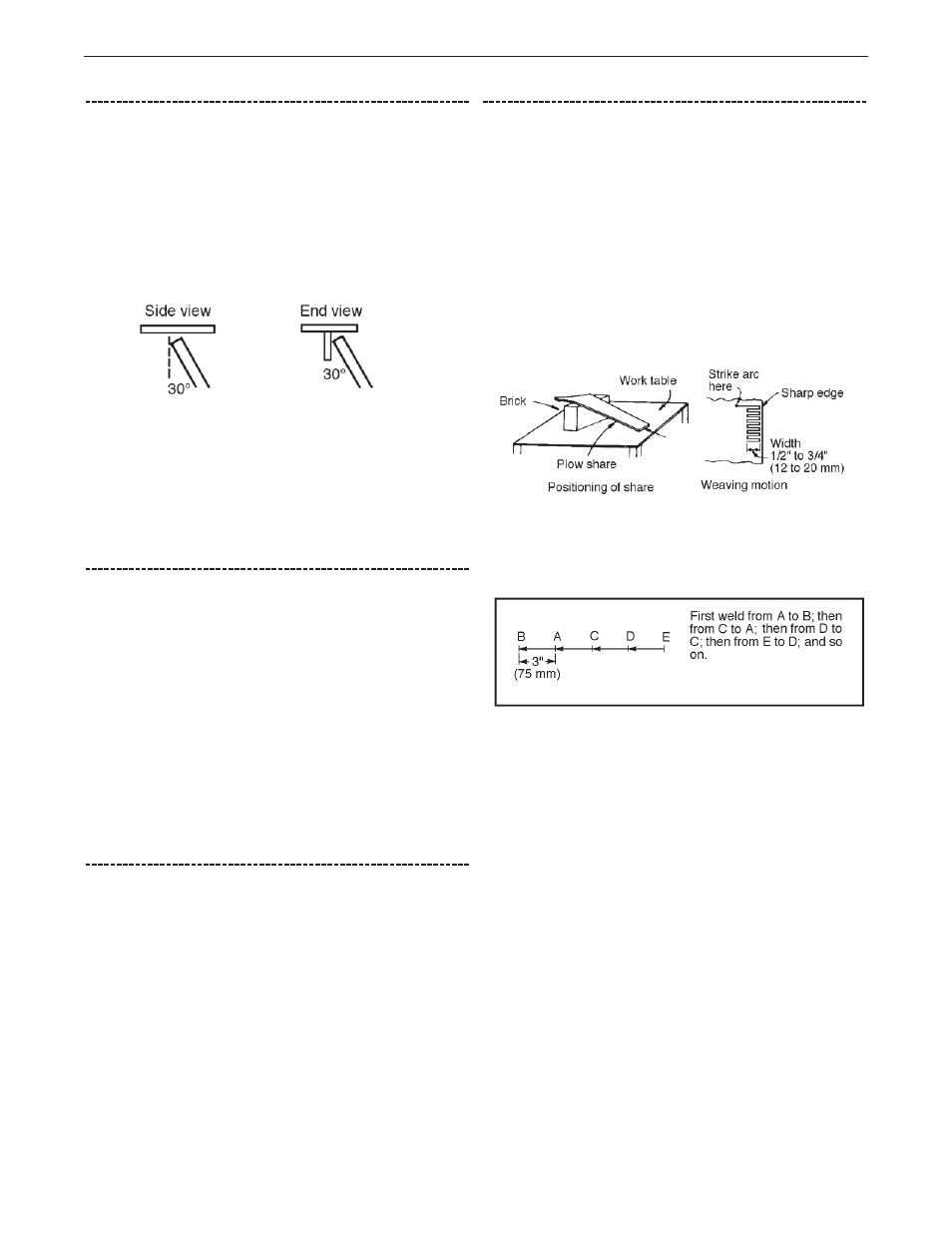

3. Hold the electrode at an angle approximately 30° off vertical,

both seen from the side and seen from the end.

The most important thing is to hold a VERY SHORT arc. (A long

arc will result in falling molten metal; a short arc will make the

metal stay.)

If necessary — and that is dictated by the looks of the molten

puddle — a slight back and forth motion along the seam with the

electrode will help prevent “dripping.”

Welding Sheet Metal

Welding sheet metal presents an additional problem. The thinness of

the metal makes it very easy to burn through. Follow these few

simple rules:

1. Hold a very short arc. (This prevents burn through, since

beginners seem to hold too long an arc.)

2. Use 1/8” (3.2mm) or 3/32" (2.4mm) Fleetweld® 180 electrode.

3. Use low amperage. 75 amps for 1/8" (3.2mm) electrode, 40-60

amps for 3/32" (2.4mm) electrode.

4. Move fast. Don’t keep the heat on any given point too long. Keep

going. Whip the electrode.

5. Use lap welds whenever possible. This doubles the thickness of

the metal.

Hardfacing

There are several kinds of wear. The two most often encountered are

as follows:

1. Metal to Ground Wear

(Plowshares, bulldozer blades, buckets, cultivator shares, and

other metal parts moving in the soil.)

2. Metal to Metal Wear

(Trunnions, shafts, rollers and idlers, crane and

mine car wheels, etc.)

Each of these types of wear demands a different kind of

hardsurfacing electrode.

When the proper electrode is applied, hardsurfacing can more than

double the service life of the part. For instance, hardsurfacing of

plowshares results in 3-5 times more acreage plowed.

How to Hardface the Sharp Edge (Metal to Ground Wear)

1. Grind the share, approximately one inch (25mm) wide along the

edge, so the metal is bright.

2.

Place the share on an incline of approximately 20-30°. The

easiest way to do this is to put one end of the share on a brick.

(See drawing.)

Most users will want to hardface the underside of the share, but

some might find that the wear is on the top side. The important

thing is to hardface the side that wears.

3. Use 1/8" (3.2mm) Wearshield™ ABR electrode at 90-105 amps.

Strike the arc about one inch (25mm) from the sharp edge.

4. The bead should be put on with a weaving motion, and it should

be 1/2” to 3/4" (12.5 to 19mm) wide. Do not let the arc blow

over the edge, as that will dull the edge. (See drawing.)

5. Use the back-stepping method. Begin to weld 3" (75mm) from

the heel of the share and weld to the heel. The second weld will

begin 6" (150mm) from the heel, the third weld 9" (225mm) from

the heel, etc.

Back-stepping greatly reduces the chances for cracking of the share,

and it also greatly reduces possible warpage.

NOTE: The entire process is rather fast. Many beginners go much too slowly

when hardfacing plow shares, running the risk of burning through the thin

metal.

BACK-STEPPING