Lincoln Electric LTW2 LEARNING TO STICK WELD User Manual

Page 5

2

LEARNING TO STICK WELD

The function of the covered electrode is much more than simply to

carry current to the arc. The electrode is composed of a core of metal

wire around which has been extruded and baked a chemical

covering. The core wire melts in the arc, and tiny droplets of molten

metal shoot across the arc into the molten pool. The electrode

provides additional filler metal for the joint to fill the groove or gap

between the two pieces of the base metal. The covering also melts or

burns in the arc. It has several functions. It makes the arc steadier,

provides a shield of smoke-like gas around the arc to keep oxygen

and nitrogen in the air away from the molten metal, and provides a

flux for the molten pool. The flux picks up impurities and forms the

protective slag. The principal differences between various types of

electrodes are in their coatings. By varying the coating, it is possible

to greatly alter the operating characteristics of electrodes. By under-

standing the differences in the various coatings, you will gain a better

understanding of selecting the best electrode for the job you have at

hand. In selecting an electrode, you should consider the following

aspects:

1. The type of deposit you want, e.g. mild steel,

stainless, low alloy, hardfacing

2. The thickness of the plate you want to weld

3. The position it must be welded in (downhand, out of

position)

4. The surface condition of the metal to be welded

5. Your ability to handle and obtain the desired

electrode

The following four simple manipulations are of prime importance.

Without complete mastery of these four, further welding is more or

less futile. With complete mastery of the four, welding will be easy.

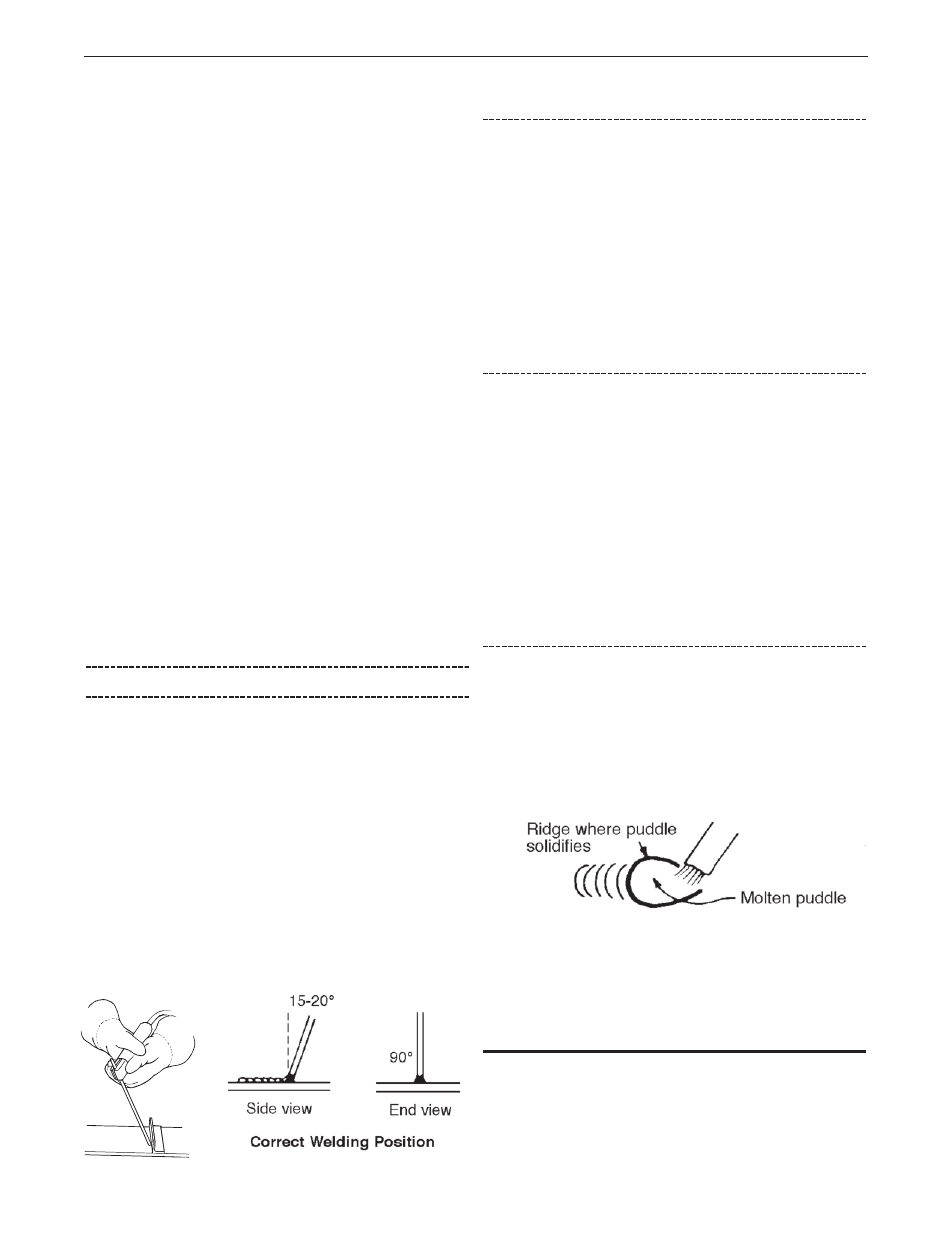

1. The Correct Welding Position

At first, you may find it easier to use the two-handed

technique shown below. This requires the use of a welding

helmet.

a. Hold the electrode holder in your right hand.

b. Touch your left hand to the underside of your right.

c. Put the left elbow against your left side.

(For welding left-handed it is the opposite.)

If you are using a hand shield, hold the electrode holder in

your right hand and the hand shield in your left. (For welding

left-handed it is the opposite.)

Whenever possible, weld from left to right (if right-handed).

This enables you to see clearly what you are doing.

Hold the electrode at a slight angle as shown.

2. The Correct Way to Strike an Arc

Be sure the work clamp makes good electrical contact to

the work.

Lower your autodarkening or fixed shade welding helmet.

Scratch the electrode slowly over the metal and you will see

sparks flying. While scratching, lift the electrode 1/8"

(3.2mm) to establish the arc.

NOTE: If you stop moving the electrode while scratching,

the electrode will stick.

NOTE: Most beginners try to strike the arc by making a fast jabbing motion

down onto the plate. Result: They either stick or their motion is so fast

that they break the arc immediately.

3. The Correct Arc Length

The arc length is the distance from the tip of the electrode

core wire to the base metal.

Once the arc has been established, maintaining the correct

arc length becomes extremely important. The arc should be

short, approximately 1/16 to 1/8" (1.6 to 3.2mm) long. As the

electrode burns off, it must be fed to the work to maintain

correct arc length.

The easiest way to tell whether the arc has the correct

length is by listening to its sound. A nice, short arc has a

distinctive, “crackling” sound, very much like eggs frying in

a pan. The incorrect, long arc has a hollow, blowing or

hissing sound.

4. The Correct Welding Speed

The important thing to watch while welding is the puddle of

molten metal right behind the arc. Do NOT watch the arc

itself. It is the appearance of the puddle and the ridge where

the molten puddle solidifies that indicate correct welding

speed. The ridge should be approximately 3/8" (9.5mm)

behind the electrode.

The tendancy is to weld too fast, resulting in a thin, uneven,

“wormy” looking bead. Watching the molten metal.

IMPORTANT: For general welding it is not necessary to weave the arc; neither

forwards and backwards nor sideways. Weld along at a steady pace. You

will find it easier.

NOTE: When welding on thin plate, you will find that you will have to increase

the welding speed, whereas when welding on heavy plate, it is necessary

to go more slowly in order to get good penetration.