Learning to stick weld, Arc rays can burn eyes and skin, Warning – Lincoln Electric LTW2 LEARNING TO STICK WELD User Manual

Page 4

1

LEARNING TO STICK WELD

LEARNING TO STICK WELD

No one can learn to weld simply by reading about it. Skill

comes only with practice. The following pages will help the

inexperienced welder to understand welding and develop

his skill. For more detailed information, order a copy of

“New Lessons in Arc Welding”, available from the James F.

Lincoln Foundation.

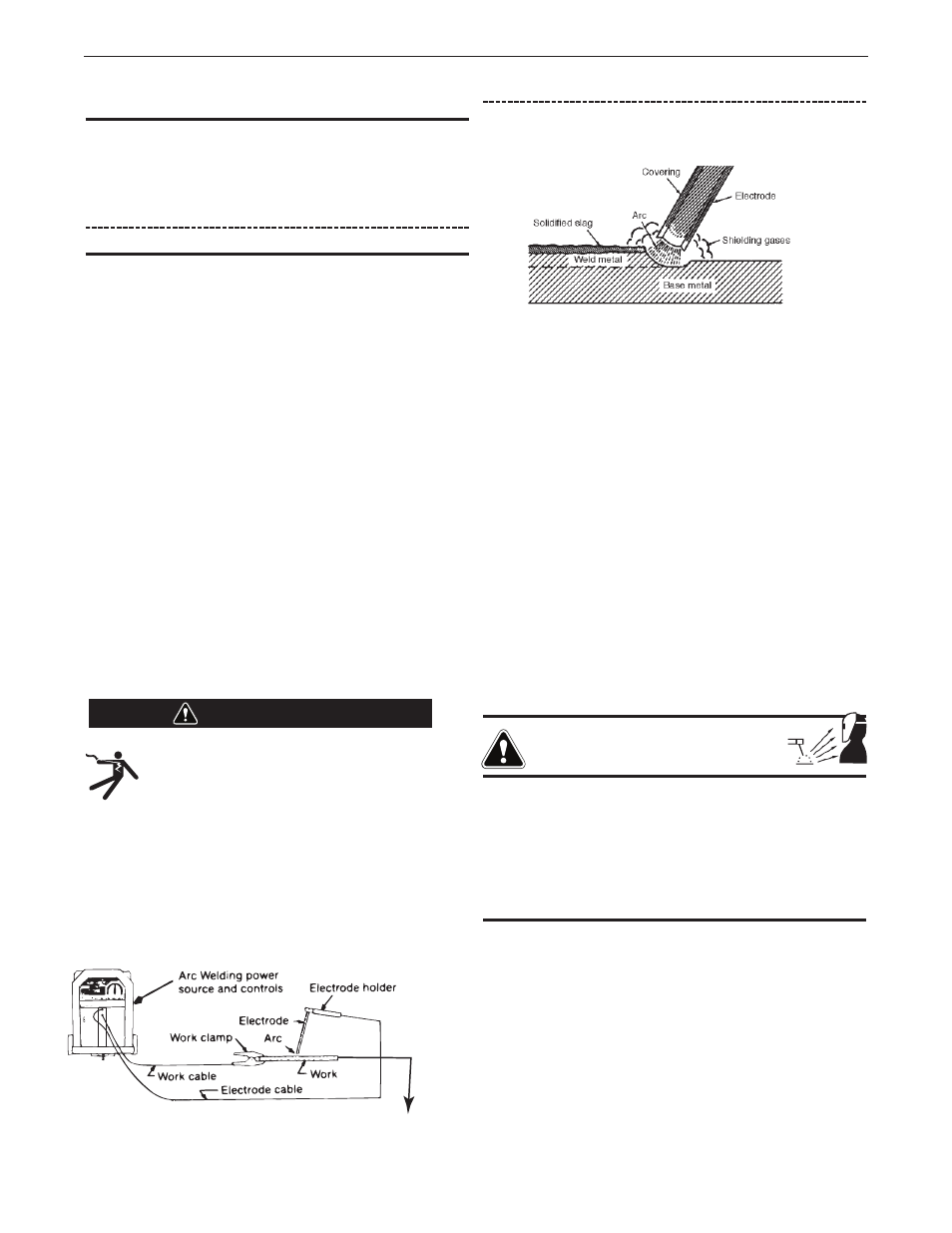

the aRc-weLDing ciRcuit

The operator’s knowledge of arc welding must go beyond the arc

itself. If you want to get the most out of your welding practice, your

knowledge of welding must go beyond the arc. You also need to

understand how to control the arc, and this requires knowledge of the

welding circuit and the equipment that provides the electric current

used in the arc. Figure 1 is a diagram of the welding circuit. The

circuit begins where the electrode cable is attached to the welding

machine and ends where the work cable is attached to the welding

machine. Current flows through the electrode cable to the electrode

holder, through the holder to the electrode and across the arc. On the

work side of the arc, the current flows through base metal to the work

cable and back to the welding machine. The circuit must be complete

for the current to flow. To weld, the work clamp must be tightly

connected to clean base metal. Remove paint, rust, etc. as necessary

to get a good connection. Connect the work clamp as close as

possible to the area you wish to weld. Avoid allowing the welding

circuit to pass through hinges, bearings, electronic components or

similar devices that can be damaged.

This arc-welding circuit has a voltage output of up to 79 volts, which

is enough to shock.

The electric arc is made between the work and the tip end of a small

metal wire - the electrode - which is clamped in a holder. The holder

is held by the welder.

ELECTRIC SHOCK CAN KILL.

CAREFULLY REVIEW THE ARC WELDING

SAFETY PRECAUTIONS AT THE BEGINNING

OF YOUR OPERATOR’S MANUAL.

A gap is made in the welding circuit (see figure 1) by holding the tip of

the electrode 1/16-1/8” away from the work or base metal being

welded. The electric arc is established in this gap and is held and

moved along the joint to be welded, melting the metal as it is moved

Arc welding is a manual skill requiring a steady hand, good physical

condition, and good eyesight. The operator controls the welding arc

and, therefore, the quality of the weld made .

What Happens in the Arc?

Figure 2 illustrates the action that takes place in the electric arc. It

closely resembles what is actually seen during welding.

The “arc stream’’ is seen in the middle of the picture. This is the

electric arc created by the electric current flowing through the space

between the end of the electrode and the work. The temperature of

this arc is about 6000°F. (3315°C.), which is more than enough to

melt metal. The arc is both very bright and very hot. If you look at the

arc with your naked eye, you risk several hours’ or days’ worth of

pain and poor, blurry vision. A welding helmet with a very dark lens,

specifically designed for arc welding, must be used whenever viewing

the arc.

Have you ever watched water flow from a garden hose onto soft soil

or earth? Eventually, the water will build up enough to displace and

dig into the soil beneath it. It may even form a small crater that then

fills with water. The arc works the same way, melting the base metal

and actually digging into it as it moves across the surface of the base

metal. The molten metal forms a molten pool or crater and tends to

flow away from the arc. As it moves away from the arc, it cools and

solidifies. A slag forms on top of the weld to protect it during cooling.

ARC RAYS CAN BURN

EYES AND SKIN.

when uSing an open aRc pRoceSS, it iS

neceSSaRy to uSe coRRect eye, heaD anD

boDy pRotection.

PROTECT YOURSELF AND OTHERS, READ

“ARC RAYS CAN BURN” AT THE FRONT OF THE

OPERATOR’S MANUAL SUPPLIED WITH THE

WELDER.

WARNING

To electrical

(earth) ground.

FIGURE 1—The welding circuit for Shielded Metal

Arc Welding(SMAW)

FIGURE 2—The welding arc