Joint types and positions – Lincoln Electric LTW2 LEARNING TO STICK WELD User Manual

Page 7

4

LEARNING TO STICK WELD

JOINT TYPES AND

POSITIONS

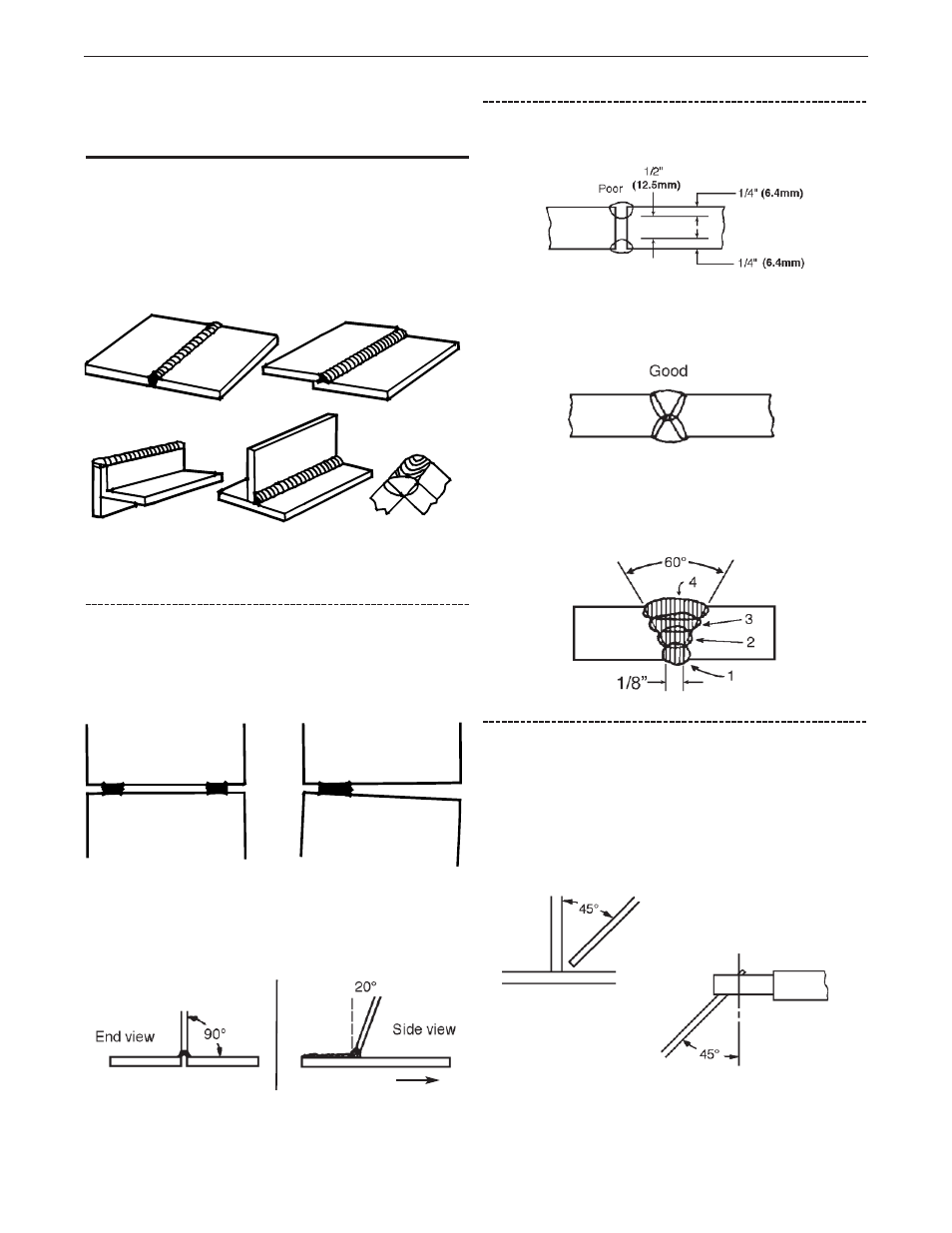

Five types of welding joints are: Butt joint, Fillet joint, Lap joint, Edge

joint and Corner joint. See Figure 3.

FIGURE 3

Of these, the Butt Joint and Fillet Joint are the two most common

welds.

Butt Joints

Place two plates side by side, leaving 1/16” (1.6mm) (for thin metal)

to 1/8” (3.2mm) (for heavy metal) space between them in order to get

deep penetration.

Securely clamp or tack weld the plates at both ends, otherwise the

heat will cause the plates to move apart. See Figure 4.

FIGURE 4

Now weld the two plates together. Weld from left to right (if right

handed). Point the Stick electrode between the two plates, keeping

the Electrode Holder tilted in the direction of travel.

Watch the molten metal to be sure it distributes itself evenly on both

edges and in between the plates. This is referred to as the “pull

technique”. On thin gauge sheet metal, use the “push technique”.

Penetration

Unless a weld penetrates close to 100%, a Butt Joint will be weaker

than the material welded together.

In this example, the total weld is only 1/2” (12.5mm) the thickness of

the material; thus the weld is only approximately half as strong as the

metal.

In this example, the joint has been flame beveled or ground prior to

welding so that 100% penetration could be achieved. The weld, if

properly made, is as strong or stronger than the original metal.

Fillet Joints

When welding a Fillet Joint, it is very important to hold the electrode

at a 45° angle between the two sides, or the metal will not distribute

itself evenly.

To make it easy to get the 45° angle, it is best to put the electrode in

the holder at a 45° angle, as shown:

Butt joint

Lap joint

Edge joint

Fillet joint

Corner joint

Weld Direction