Pump - driveshaft - hyd tank figure 18, Figure 20 figure 21, Figure 19 – Alamo Interstater TS-100A User Manual

Page 24

Interstater (NH TS-100A , 115A , 125A & 135A Asy. Manual) 06/04

© 2004 Alamo Group Inc.

Section 3 - 8

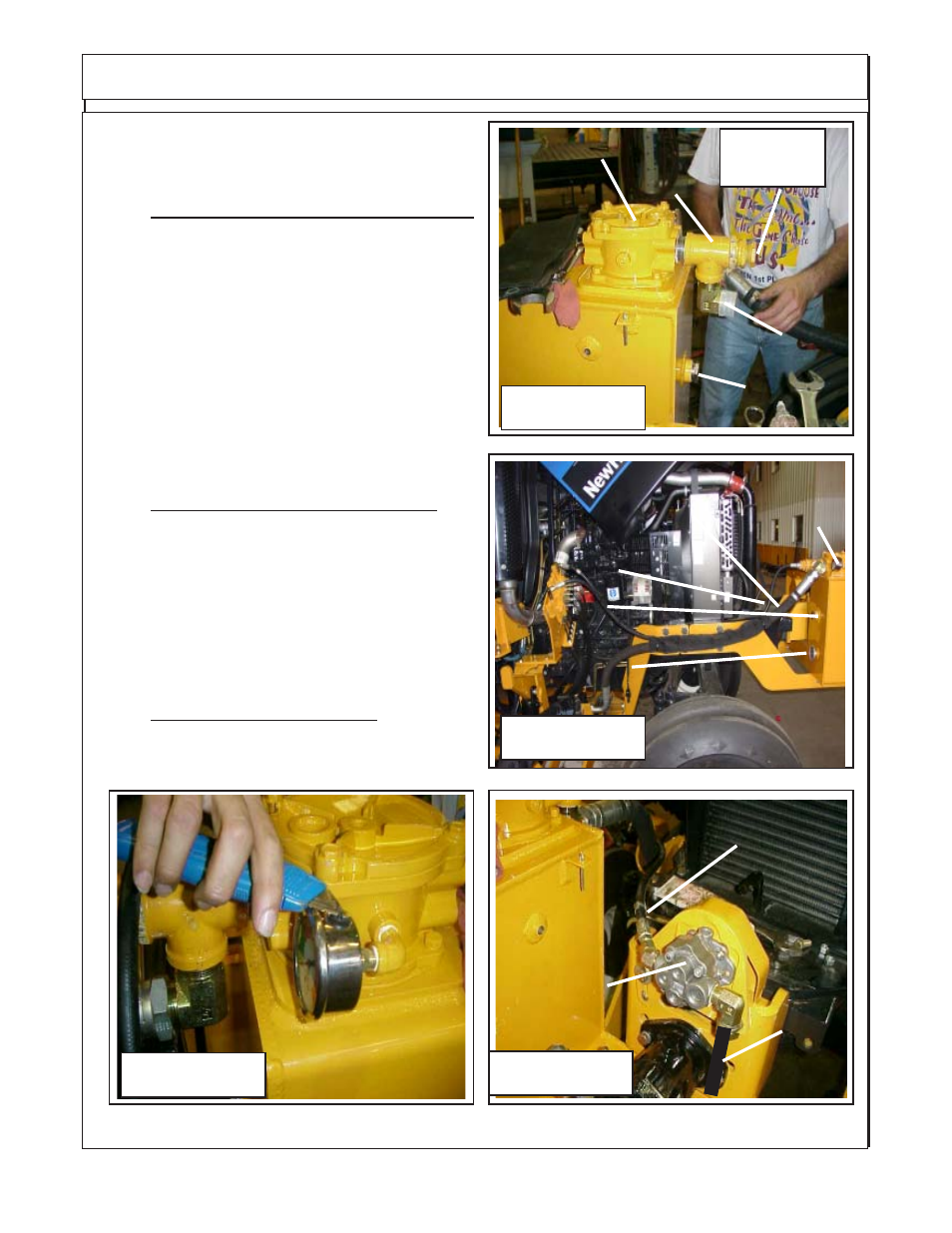

Pump - Driveshaft - Hyd tank

Figure 18

Tank Return

Filter

Install Driveshaft, Pump & Tank:

(continued)

23.

Install Hose Fittings into Return Filter in Tank.

There is a return filter in the top of the RH side of tank.

In the end of the filter housing install a Tee Fitting with

an Elbow in it, the tee fitting should point outward as

seen in figure 19. In the end of the Tee there will be

reducer to allow the installing of a smaller hose. This

reducer is where the return hose from the control

valve will connect (See Figure 18, 19 & 25). The

elbow fitting in the tee should be turned downward at

approx a 45 degree angle (see Figure 19 & 25) .

Installing these fittings in this way will allow the oil

cooler to be slid out for maintenance without hydrau-

lic hoses interfering with cooler.

24.

Install Return Filter Pressure Gauge. The

return filter pressure gauge screws into the side of

the return filter housing. This gauge is a low pres-

sure gauge that is marked in green and red areas.

(See Figure 19). The Oil Pressure return gauge has

a rubbery tip on top of it, the tip till have to have the tip

of it cutoff. Using a utility knife (or suitable knife) cut

the tip off now (See Figure 20). This will need to be

done before unit is run.

25.

Install the Oil Level Sight Glass. The Oil Level

sight Glass screws into the Hydraulic tank. This is to

covered with oil when tank is a at operating level.

(See Figure 18 & 19)

Elbow

Fitting

Oil Level

Sight Glass

Pipe

Tee

Reducer

Fittting

Figure 20

Figure 21

To Control Valve, Pressure

Line ("P" Port on Valve)

Tank

Suction

Line

Cyl. Control

valve Supply

Pump

Return Hose

from 4 Spool

Control valve

Port Marked "T"

Return Hose

from Wing

Motors

Return

Pressure

Gauge

Oil Level

Sight Glass

Oil Temperature

Gauge

Figure 19