Warner Electric PCC-825, PCC-1000, PCC-1225, PCC-1525 User Manual

Page 6

6

Warner Electric • 800-825-9050

P-206 • 819-0519

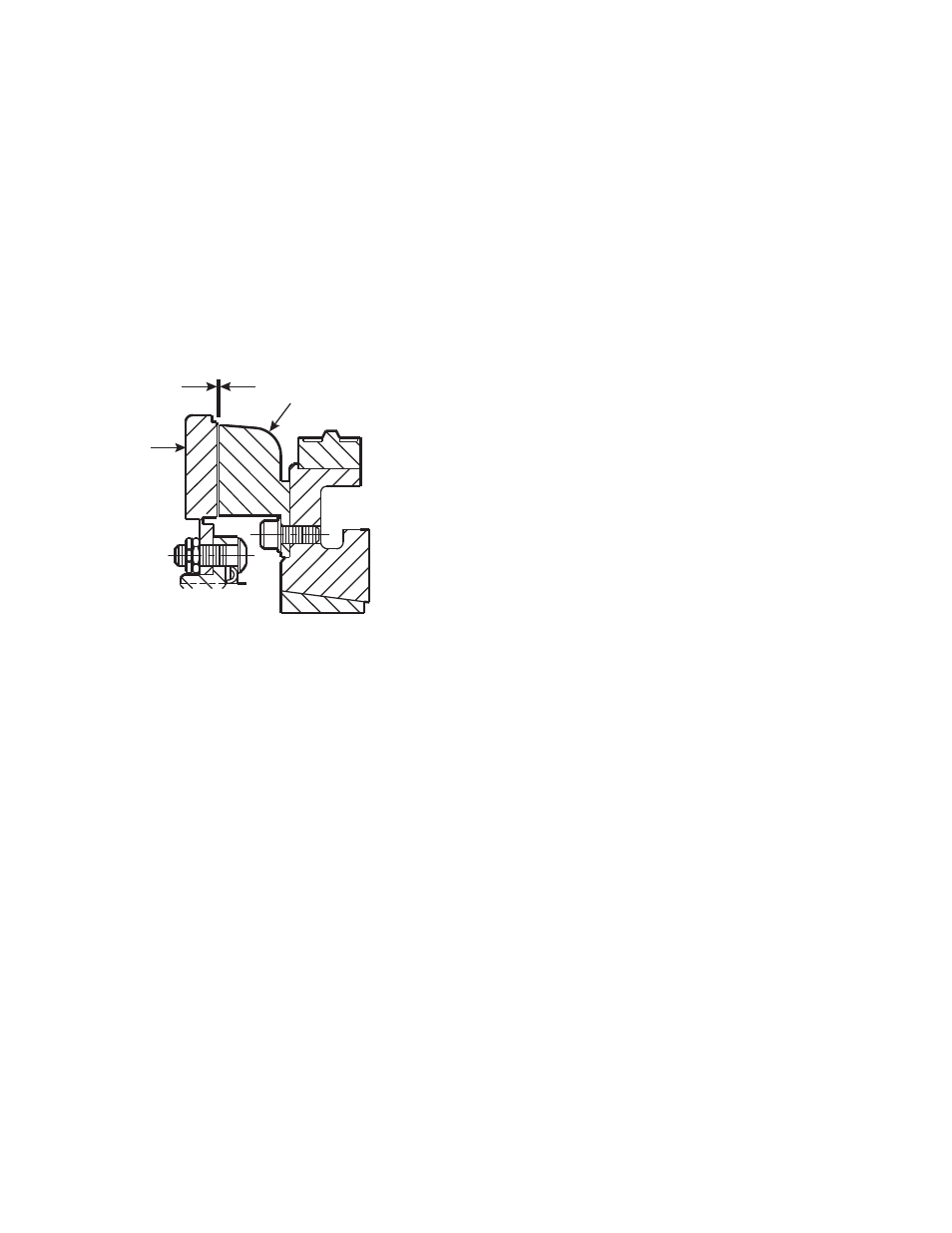

D. Mounting the Armature Assembly

1. Slide the armature assembly and

customer supplied pulley, sprocket or hub

onto the shaft.

If the magnet and magnet hub assembly

has been secured to the shaft first, then

adjust the magnet's position to allow

approximately 1/32-inch between the two

faces.

Once this 1/32" gap has been set, it will be

automatically maintained throughout the life

of the unit. (See Figure 10)

2. Secure the armature assembly and

customer supplied pulley, sprocket and hub

in this position by a) retainer rings, b) set

collars, c) shoulder on the shaft, or d) any

combination of these. The best method will

depend on the characteristics of each

application.

E. Mounting the Brushholder

1. The brushholder is mounted on a bracket

which must be furnished by the customer.

The bracket must be firmly secured to pre-

vent vibration which could cause improper

contact between the brushes and collector

ring.

2. The distance from the centerline of the

shaft to the top of the brushholder should

be 5-3/4". Maintaining this distance will

assure proper spring tension on the brush-

es and maximum wear follow-up. A

detailed dimensional drawing is included

with each brushholder.

1/32-inch

Armature

Magnet

Figure 10