Setting application torque – Warner Electric Dairy Cap Chuck User Manual

Page 2

2 Warner Electric • 800-825-9050

P-2021

Setting Application Torque

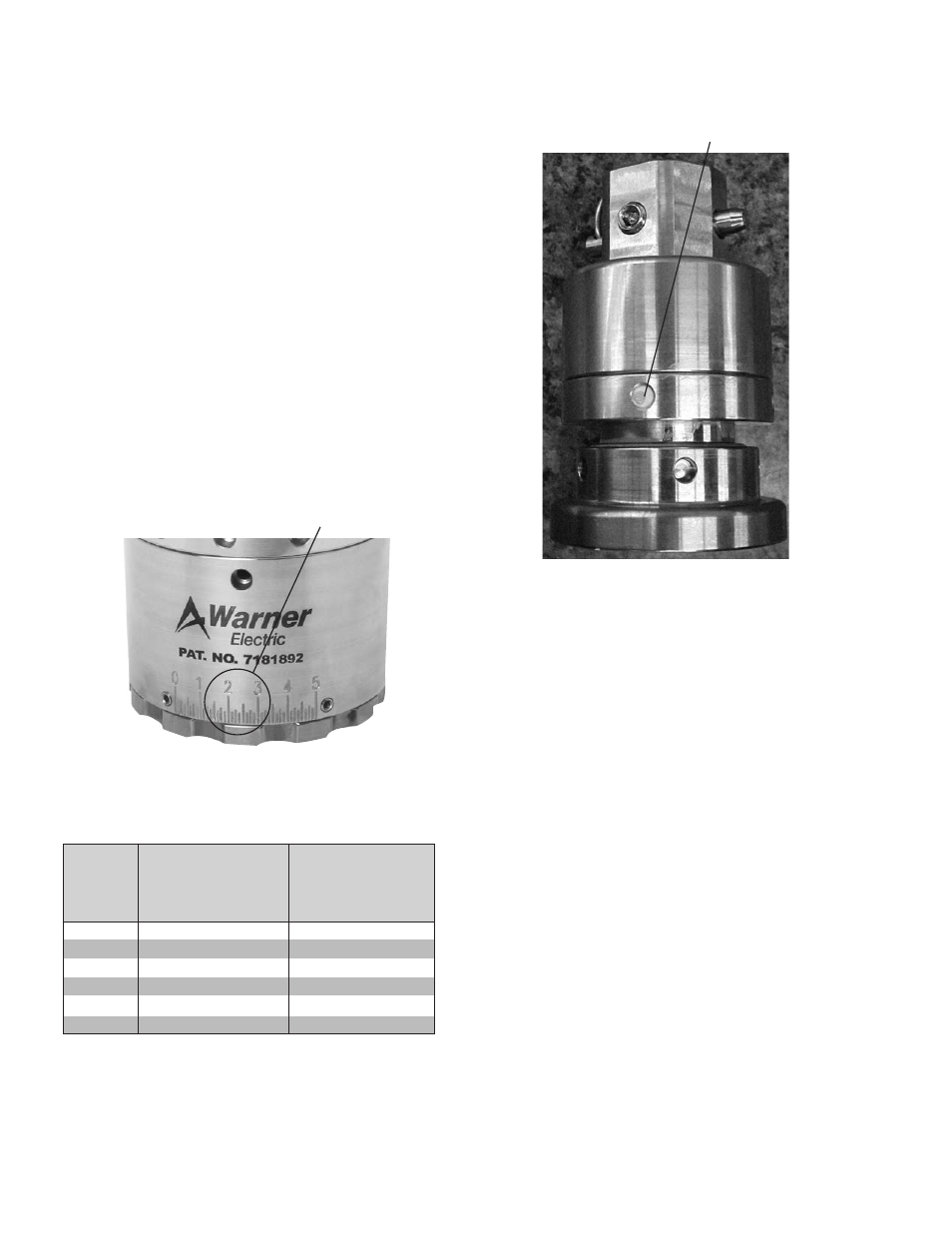

1. Determine initial clutch setting from torque chart

below.

2. Loosen the torque adjustment screws. Rotate the

adjustment ring using the face spanner wrench to

the desired setting and then retighten the torque

adjustment screws. Do not use the set screw in

the slot on the backside of the housing for torque

adjustment. Tighten set screws to 8-10 lb-in.

Over tightening is not necessary and will strip the

screws or possibly damage the housing body.

3. For optimum results, check setting with a torque

wrench and FIX-0115* or FIX-0138.

*For use with DBJ closure

Application

Torque Setting

0.00

3.00

11.00

1.00

4.00

12.00

2.00

8.00

17.00

3.00

13.00

22.00

4.00

16.00

26.00

5.00

18.00

28.00

Application Torque Setting Charts

Clutch

Setting

Application Torque

Standard Torque

Units (lb-in)

Application Torque

High Torque Units

(lb-in)

Figure 1

Recommended Maintenance

For CHF38-035 Chuck

Grease Port

Disassemble, clean, and replace all wearing

parts in the headset every 7000 hours of

machine run time.

- See rebuild instructions for detailed information on

disassembly and assembly of Warner headsets.

- Dependent upon machine speed and washdown

procedure, some environments may require more

frequent rebuilds.

- CHF38-035 chucks cannot be submerged in

water. Proper cleaning procedures for the chucks

include wipe down operations or foaming. If

necessary chucks can be taken apart, cleaned

and rebuilt.

- Chucks can be greased if needed using lubrication

hole in chuck and needle fitting on grease gun.

Do not over grease as this will cause the chucks to

stick.

Note: CHF38-037 and later model chucks may be

submerged in water or COP/CIP cleaners. No

re-greasing is required.

Figure 2