Tracer TP-9367 Marksman II AM12002 User Manual

Page 12

12

Mechanical Malfunctions

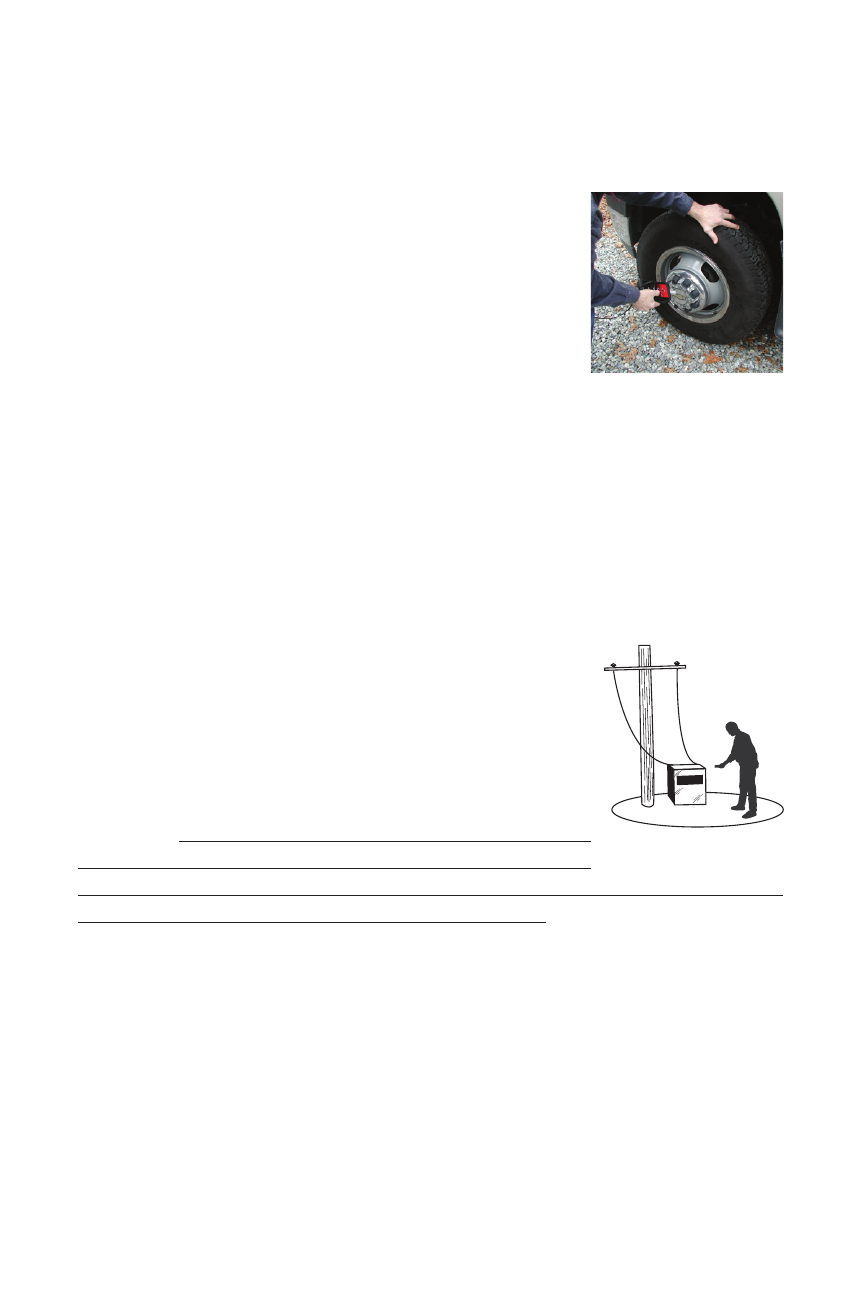

The photo to the right shows a typical way to

inspect a potential wheel bearing problem. In

this case, the air probe is used since the wheel

is being turned while listening for the sound of

the bearings. The tip of the probe is kept 2-3

inches from the inspection area. Response

can sometimes be optimized by removing the

wheel and using the contact probe to touch

the stationary center hub. This applies to motor

housings as well when checking motor bearings. The contact probe

is also used in the same manner for investigating fuel injectors and

coil-over-shock suspension systems. Touch the tip of the metal

probe to the surface area being tested. Correct operation sounds

one way, while malfunction sounds another way. You will easily

hear the difference.

Electrical Corona Discharge

At right is a typical application using the

Marksman II to detect possible electrical

malfunctions by listening to the electrical

corona discharge associated with power

switches and breaker boxes.

As with all

potentially dangerous situations, use

caution.

Use the hollow air probe or use the

receiver alone when inspecting electrical

conditions and always keep a safe distance between the air

probe tip and the metal panel surfaces. The Marksman II is

highly sensitive to picking up voltage breakdowns. The resultant

ultrasonic sound has been described as sounding like “frying bacon.”

Pressurized and Vacuum Leaks

Applications for pressurized type inspections are endless,

including compressed air or gas of any kind, air brake systems,

pipes/pipelines, steam systems, water lines, manifolds, and

likewise all vacuum systems.

Note: Ultrasonic detection relies on

detecting the sounds associated with the turbulence of the fluid or