Foredom K.1030 User Manual

Page 3

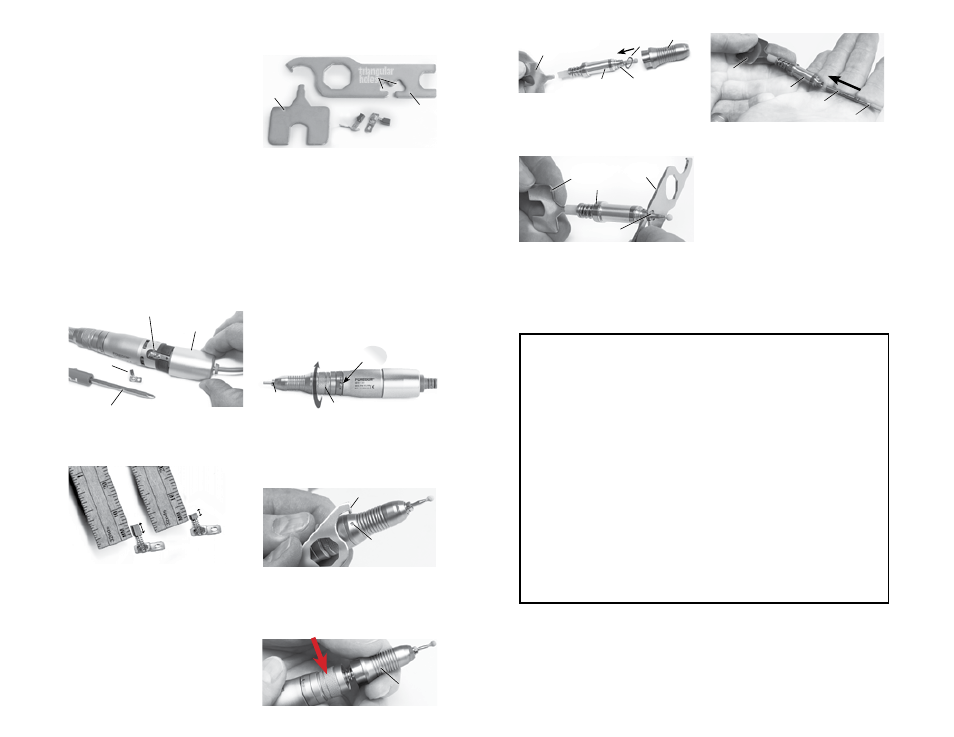

4. Carefully remove the spindle assembly

from the nose cone. Be sure to place the

thin washer back on the collet end of

the spindle assembly before reassem-

bling the handpiece. Don’t misplace it!

5. Insert the chuck joint wrench into the cross

section of the back end of the spindle assem-

bly. Insert the collet head into the collet size

triangle hole on the chuck wrench and turn

the chuck wrench counterclockwise to loosen

the collet while holding the chuck joint wrench

with your other hand.

Repair Services

Authorized repair service is available at the

Foredom factory in Bethel, CT. Send items

for repair to the factory marked “Attention:

Repair Department”. Enclose the item(s), a

packing list and description of the problem

or repairs required plus your daytime phone

number and email address. Estimates of

Maintenance

continued

Micromotor Supplies

K.1030 Micromotor Kit comes with a chuck

wrench and chuck joint wrench for changing

collets (Wrench Set p/n HP4-993), and spare

pair of motor brushes (p/n HP8-163) as

shown at right.

Checking and

Changing Carbon Brushes

A spare set of carbon brushes is supplied

with each handpiece. They come packed in

the handpiece box. Depending on how long

the handpiece is used each day, the brushes

should be checked for wear about every 200

hours of use and replaced when the brush is

less than 1mm (1/16

″) long.

1. With handpiece power cord disconnected

from control box, unscrew protective cap

from rear of motor by turning counterclock-

wise while gripping the handpiece body. (It

has a standard right hand thread.)

2. With small crosspoint screwdriver remove

screws and brush assemblies one at a time.

Check length of carbon brush from spring to

end of brush.

Brushes should be replaced if they are less

than 1mm long. Replace both motor

brushes with new ones even if only one

of them looks worn.

Limited Warranty

Foredom warrants all parts of this product (except the Lithium Ion Battery p/n HP8-B1800 which

has a one year warranty) to be free of defects in material or workmanship for a period of two years

after purchase. Blackstone Industries, LLC d/b/a The Foredom Electric Company warrants, to the original

purchaser only, that its products will be free from defects in material or workmanship for the applicable

period of time indicated above following the purchase date. During the warranty period, the defective

product will be repaired or replaced without charge or, at our sole option, the purchase price will be re-

funded. This warranty does not cover damage caused in transit or by accident, misuse or ordinary wear

ALL IMPLIED WARRANTIES INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES OF FITNESS FOR

A PARTICULAR PURPOSE AND MERCHANTABILITY, ARE LIMITED IN DURATION TO THE APPLICABLE

WARRANTY PERIOD. IN NO EVENT WILL WE BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES. Some states do not allow limitations on how long an implied warranty lasts or the exclusion

or limitation of incidental or consequential damages, so the above limitations or exclusion may not

apply to you.

At our sole option, repair, replacement or refund will be made if the product is returned postage

prepaid to:

Foredom Electric Company, 16 Stony Hill Road, Bethel, CT 06801

All warranty repairs must be done at the factory at the address above. We will not pay any shipping

or transportation charges. This warranty only covers the original purchaser of the product. Proof of

purchase may be requested. Some states do not allow limitations on how long an implied warranty

lasts, so the above imitation may not apply to you. This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Installing/Changing Collets

Important Note: Always keep a test

bur or accessory in both collets when

changing collets.

1. The Handpiece has either a 2.35mm

(3/32

″) or 1/8″collet installed. 2.35mm

(3/32

″), 1/8″ and 3mm collets are available

separately. They can be installed with the

collet changing wrenches, described below.

Caution: Finger tightening is not enough.

A wrench MUST be used to tighten the

collet fully several turns beyond the

point of initial resistance. If collet is too

loose or absent, the spindle will not turn

and it will damage the motor.

A bur or test bur MUST be in the

collet when changing collets!

2. With a test bur in the collet, turn the

Locking Ring toward the secure “S” (closed)

position. Do NOT remove the locking

ring or spring!

3. Place the Chuck Wrench hook into the

notch on the H.MH-130 handpiece nose

cone and unscrew it counterclockwise (see

photo above).

Do NOT remove

the locking ring or spring.

hook

notch

nose cone

chuck

joint

wrench

chuck

wrench

triangular

holes

motor brushes HP8-163

Set of 2 wrenches HP4-993 and spare

motor brushes come packed in handpiece box.

spindle assembly

nose cone

washer

chuck

joint

wrench

collet

with bur

chuck

wrench

spindle

assembly

chuck joint

wrench

spindle

assembly

collet

chuck joint

wrench

collet with bur

bur

protective

cap

spare

motor brush

motor brush

installed

crosspoint

screwdriver

New motor brush

Worn

motor brush

REPLACE!

6. Remove collet and insert new size collet,

with a test bur inserted. Use the triangular

hole in chuck wrench to re-tighten collet by

turning clockwise. Be sure to securely

tighten collet! Rotate the collet to align

the cross-shaped end of the spindle assem-

bly with the cross-shaped motor drive inside

the handpiece. Carefully review steps 4, 3,

2, and 1 to reassemble the handpiece with

the changed collet. Re-attach and tighten

nose cone.

Please retain your proof of purchase

for warranty repairs.

repair cost will be made upon request. It

is our policy not to proceed with a repair

without your approval if the cost (labor plus

parts) is more than fifty percent of the cost

for a new replacement. You will be notified

and advised of the cost to repair and to

purchase a new replacement.

knurled locking ring

collet

Close

R

I

S