Important, Assembly instructions, Operation – Foredom PowerGraver User Manual

Page 4: Connecting motor and control, Connecting the handpiece, Installing accessories, Changing collets, Adjusting impact of hammer, Stroke/speed adjustment

Assembly Instructions

Always make sure your power tool is

unplugged during assembly.

The PowerGraver ships with the shaft and

sheath assembled, however,

please check to

be sure that the tip of the shaft extends

3⁄4

″ beyond the end of the sheath. If it

needs to be

adjusted, place the

entire unit on a flat

surface with shaft

and sheath

extended straight.

Adjust the

exposed tip of the flexible shaft so that it

extends 3/4

″ beyond the sheath, as shown.

This is done by loosening the set screw in the

motor connector and moving the sheath in or

out of the motor connector. When the correct

adjustment is made, tighten the set screw in

the connector. See photo on bottom of page 6.

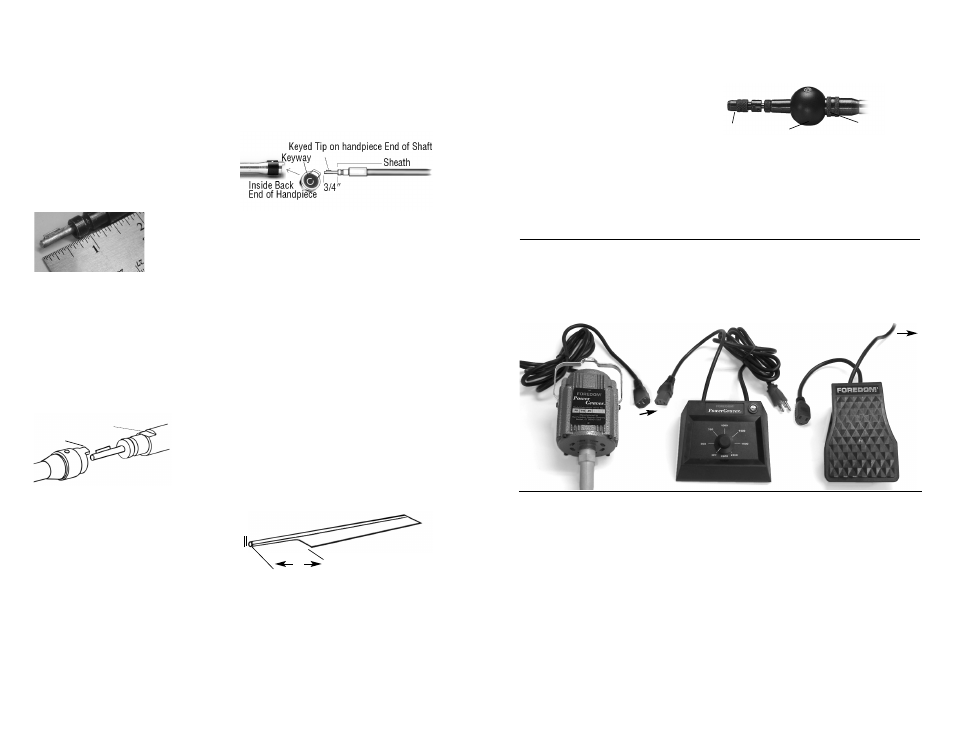

Connecting the Handpiece:

Unlike other Foredom Handpieces, the H.9D

handpiece has a tab on the end where it con-

nects to the shaft and sheath (see drawing).

The tab slides over the flattened edge on the

sheath. The H.9D will not fit other Foredom

sheaths. However, other handpieces can

be attached to the PowerGraver shaft for

slow speed jobs.

The Foredom PowerGraver Kit K.2293 also

includes collet changing wrenches, handpiece

oil, flexible shaft grease, 32-minute instructional

DVD and booklet.

flattened edge of sheath

tab

Operation

Read all safety instructions on pages 2 and 3

before using your Foredom PowerGraver.

Wear proper eye and face protection to pro-

tect yourself from injuries caused by flying

debris or chips from the work being done.

Your Foredom motor may be operated in a ver-

tical or horizontal position. If the motor is hung

up above a workbench, be sure to

fasten it securely.

Do Not Bend the Flexible Shaft at a Tight

Angle. Shafts and sheaths last longer when

they are used without sharp bends. If used at

angles or loops, wear will occur at the points of

greatest friction.

4

IMPORTANT!

1. In addition to aligning the outer tab, the

keyed tip at the end of the flexible shaft must be

lined up with the keyway inside the end of the

handpiece. Do this by looking into the rear of

the handpiece before pushing it on. If it is not in

line, turn the key tip or the handpiece to the

correct position while being sure to also align

the outer tab with the flat outer edge of the

shaft. Both connections must be properly

aligned and they move or turn independently

of eachother. The handpiece is easy to remove

from the flexible shaft. To remove, simply pull

the handpiece off the shaft and sheath with a

firm grip.

2. Install the Palm Rest. Slide the larger

opening over the front of the handpiece and

place it as close to the impact adjustment ring

as possible. Rotate the palm rest to the most

comfortable position and tighten set screw with

a small flat-head screwdriver. Use of the palm

rest is a matter of personal preference. You may

find that the palm rest is more appropriate for

some applications than others.

Installing Accessories

The PowerGraver can take standard gravers and

other accessories with 1/16

″ (1.6mm), 3/32″

(2.35mm), 1/8

″ (3.18mm) and 3mm diameter

shanks. Choose the correct accessory for your

particular application. We recommend that you

grind and trim standard graver shanks to the

dimension illustrated above.

Locate and identify all components before

discarding the packing list and materials that

came with your PowerGraver.

An optional on/off foot switch is available.

To install an accessory, insert one wrench into

the wrench flats of handpiece. Insert other

wrench into wrench flats of chuck nut. Loosen

chuck nut. Insert accessory as far as possible

into the collet. Tighten chuck nut. Test for a

secure hold by pulling on accessory. Remove

wrenches. To release an accessory, follow the

same steps.

Changing Collets

The H.9D handpiece has collets to fit four

different shank sizes: 1/16

″, 3/32″, 1/8″ and

3mm. To use the correct collet size for the

shank of the accessory you are using, it is

sometimes necessary to change a collet. The

1

″

1

⁄

8

″

Grind corners of shank

to dimension shown for

snug fit into collet.

collet holds the accessory securely in the

handpiece. Unscrew the chuck nut and slip out

collet. Slip in new collet and screw the chuck

nut back into place.

Adjusting Impact of Hammer

The impact of the stroke is adjusted by rotating

the knurled ring on the handpiece clockwise

towards the chuck nut for a lighter impact –

and counterclockwise towards the back for a

heavier impact.

Chuck Nut

Impact

Adjustment Ring

Palm Rest

Do Not Force the Tool. Let the speed of

the tool do the work. Avoid using too

much pressure.

Stroke/Speed Adjustment

The strokes per minute are determined by

motor speed, which can be varied from 500 to

2,800 strokes. Set the speed desired with the

knob on the Variable Speed Dial Control. Both

speed and impact can be adjusted while the

motor is running. The On/Off Foot Switch will

turn the motor on or off at the speed set on the

speed control.

On/Off

Foot

Switch

Optional

Variable

Speed

Dial

Control

Motor

Plug into wall outlet

Plug

into wall

outlet or

Optional

Foot

Switch

3. Plug the Optional On/Off Foot Switch into

an electrical outlet.

5

Connecting Motor and Control

1. Connect male plug of motor to female

cord of Dial Control.

2. Connect male cord of Dial Control into wall

outlet or into female cord of Optional On/Off

Foot Switch.