The powergraver, Maintenance procedures, Important – Foredom PowerGraver User Manual

Page 3

6

The PowerGraver

®

Kit

The Foredom

®

PowerGraver is a complete

power tool used to perform a wide variety of

tasks such as engraving, stone setting, bright

cutting, bead raising, and other applications

requiring the use of a graver or a hammering

effect. Foredom power tools are manufactured to

high standards of precision and with proper use

and regular maintenance will give you years of

trouble-free performance.

The Foredom PowerGraver Kit K.2293 consists of

a permanent magnet DC motor, flexible shaft with

neoprene sheath, dedicated handpiece with palm

rest, variable speed dial control, and accessories

listed at left.

•

Always use dust collection, respirator,

or face mask to prevent inhalation of

dust particles from workpiece

or abrasives.

•

Never use or continue to use a graver or

accessory which appears to be damaged.

Inspect each graver for cracks or flaws

before using it.

•

Always insert the shank or arbor of an

accessory or mandrel into the collet of

the handpiece as far as possible in order

to provide proper support and tighten the

collet securely.

•

Never use excessive side pressures

which may tend to bend or break the

shank or arbor of an accessory. Let the

impact of the hammer do the work.

•

Do not stall the motor by jamming or

using excessive pressure on the accessory.

This can result in damage to the motor or

flexible shaft.

•

Never operate the motor with the outer

sheath removed from the flexible shaft.

•

Always disconnect the power cord

before servicing the motor or removing

the flexible shaft or sheath.

•

Never operate your power tool during a

perceptible power decrease. Turn power

tool off and do not use until power is

fully restored.

•

Use proper grounding procedures. This tool

should be grounded while in use to protect

the operator from electric shock. The tool is

equipped with an approved 3-conductor cord

and a 3-prong grounding type plug to fit the

proper grounding receptacle. The green (or

green and yellow) conductor in the cord is

the grounding wire. Never connect the green

(or green and yellow) wire to a live terminal.

If your unit is for use on less than 150 volts,

it has a plug that looks like sketch A in the

diagram below. An adapter (sketches B and

C) can be used for connecting plugs as

shown below to 2-prong receptacles. The

green colored rigid ear, lug, etc., extending

from the adapter must be connected to a

permanent ground such as a properly

grounded outlet box.

Some jurisdictions,

including Canada, prohibit the use of 3 to

2 prong adapters. Where prohibited, they

should not be used. Use only 3-wire

extension cords that have 3-prong grounding

type plugs and 3-pole receptacles that accept

the tool's plug. Always disconnect the power

cord before servicing the machine. Never use

in an area where flammable vapors are present.

Accessories

Collets: HP602 (1/16

″

),

HP603 (3/32

″

), 604 (1/8

″

)

and HP605 (3mm)

Gravers: A-G91 #52 Round

A-G92 #3 Onglette

A-G93 #2 Bevel

A-G94 #40 Flat

10215 Carbide Stylus

10177P Anvil Point

3

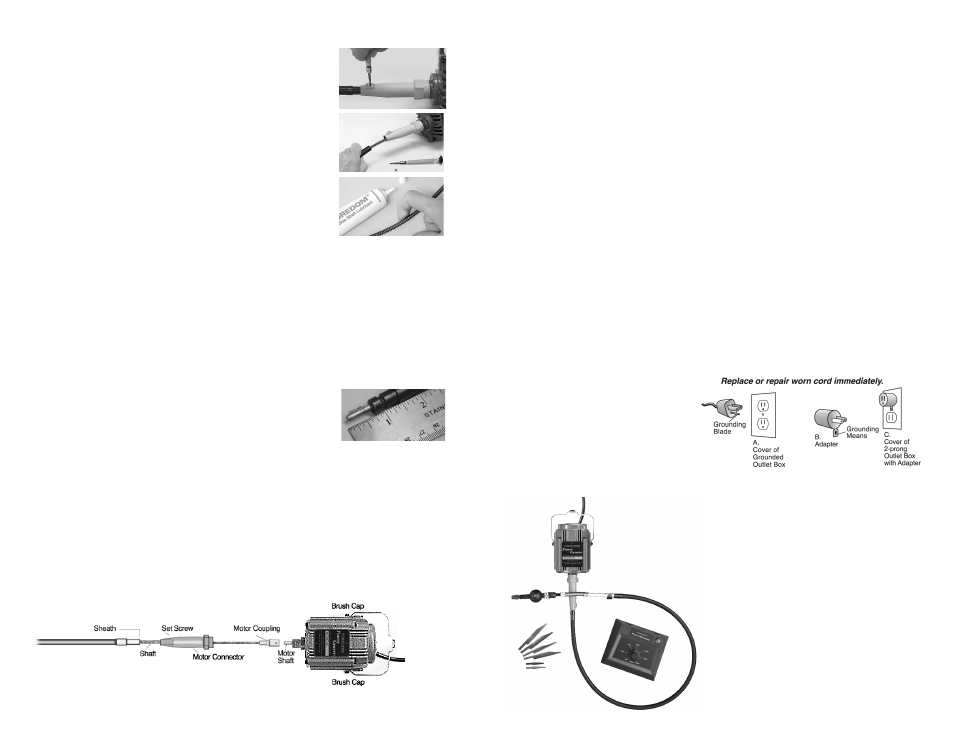

Exposing the Inner Shaft

1.Remove handpiece

(see page 4).

2. Loosen set

screw on motor

connector.

3. Slide outer

sheath out of motor

connector and wipe

shaft clean.

4. Apply a very light

coating of lubrication

to shaft starting at the

top and working

downward to about

one inch from the handpiece end. Apply grease

with your finger tip or small brush. Don’t overdo,

apply a light film of grease. Once the machine is

running, the shaft itself will spread the grease. If

too much grease is applied, the excess will work

its way into the handpiece and will make the

handpiece run hot. For this reason, apply a bit

less near the handpiece end of the shaft.

Never operate the motor with the outer

sheath removed from the flexible shaft.

5. Replace and adjust

sheath so that shaft

key tip extends 3/4

″

(19mm) from sheath.

Retighten the set

screw in motor connector.

6. Clean outside of sheath by wiping with

a cloth.

7. Hang and run the motor for about 10 minutes

before attaching the handpiece to allow enough

time for the grease to warm up, spread and

drain off. Wipe off any excess grease at tip end

of sheath.

8. Re-attach handpiece.

Maintenance Procedures

Always make sure your power tool

is unplugged during maintenance!

It is very important to routinely clean your

Foredom

®

Power Tool and lubricate the shaft

(NOT the motor), especially in areas that

generate a lot of dust.

Dirt and improper lubrication are the most

common causes of poor operation and

excessive wear.

Always disconnect power tool before

cleaning or servicing.

Note: The M.PGX has permanently

lubricated ball bearings and does not

require additional lubrication.

Routine Cleaning of Motors

Foredom Motors need air circulation through the

motor housing to remove waste heat and cool the

windings. Inlet and outlet slots provide the means

for air flow. However, saw dust and conductive

debris (like metal filings or gold dust) can enter in

through these slots. If not cleaned regularly, dust

can collect, making a bridge between parts,

causing an electrical short.

In high dust environments, Foredom

recommends cleaning the motor every

40 hours of use.

To remove dirt and dust buildup, motor brushes

should be removed, cleaned and replaced, and air

should be blown through the motor.

Routine Cleaning and

Lubrication of Flexible Inner Shaft

The shaft should be checked, wiped clean, and

re-lubricated with grease every 50 hours of use.

With every 200 hours of use, the shaft should be

thoroughly cleaned with solvent and lubricated.

Use Foredom flex shaft grease (p/n MS10006) or

high quality white lubricating grease.

IMPORTANT!