Important, Shaft and sheath adjustment, Replacement of motor brushes – Foredom Series SR User Manual

Page 14: Installation of new shaft, Visit

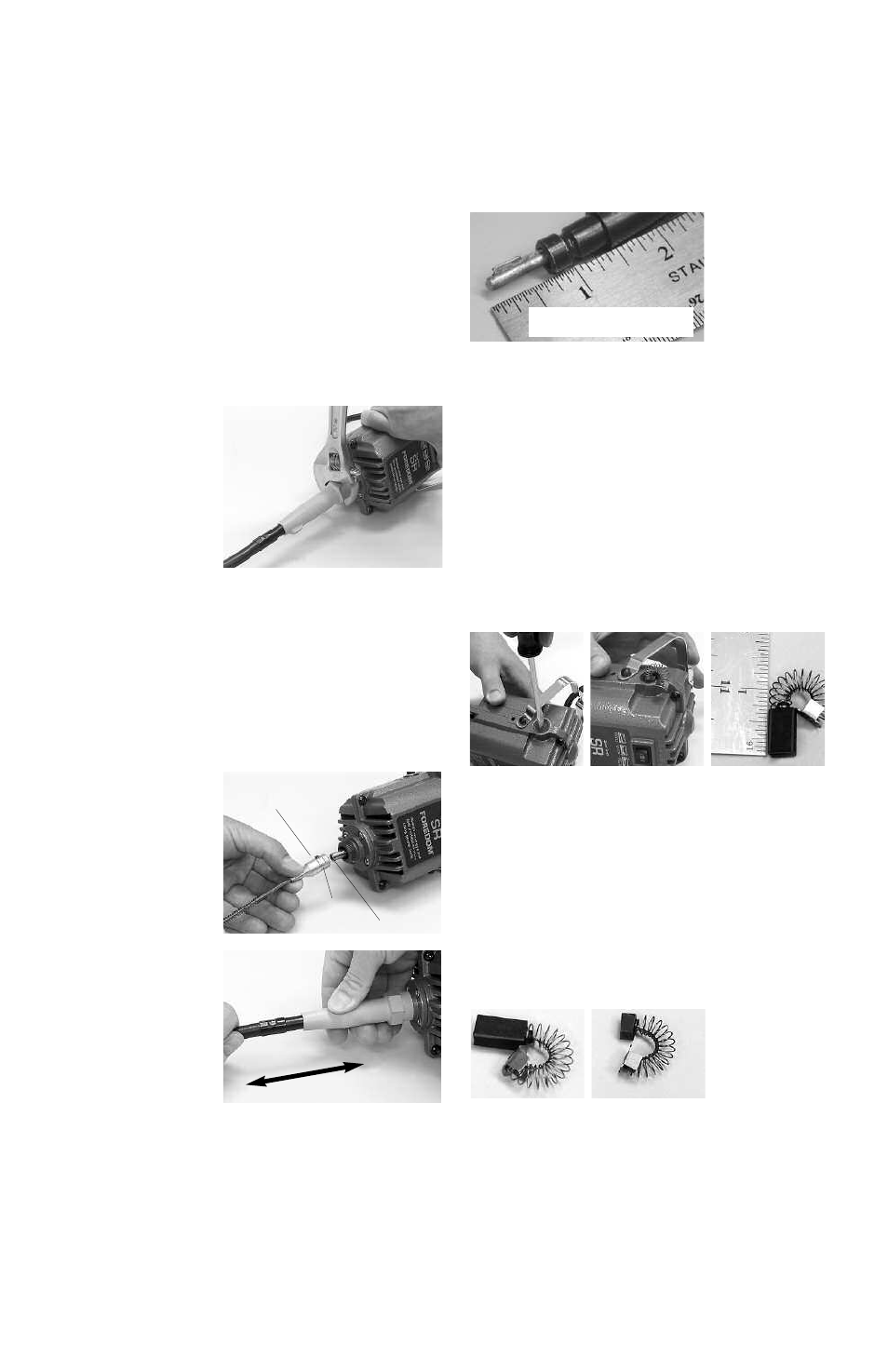

Shaft and Sheath Adjustment

Place the entire unit on a flat surface with

shaft and sheath extended straight.

Adjust the exposed tip of the flexible shaft

at the handpiece end so that it extends 3/4

″

(19mm) beyond the sheath.

This is done by moving the sheath in or out

of the motor connector. When the correct

adjustment is made, tighten the screw in

the motor connector.

Replacement of Motor Brushes

Motor brushes should be checked for wear

periodically. When new they are approximately

3/4

″ (19mm) long. Replace them when they

have worn to 1/4

″ (6mm). To remove brushes,

disconnect motor power cord and unscrew the

brush caps. Remove the worn motor brushes,

replace with new motor brushes, and screw

motor brush caps back on. Be sure to replace

both motor brushes even if one of them is less

worn than the other.

New Motor

Brush

Motor that

needs

Brush

replacement

14

Always make sure your power

tool is unplugged when conducting

maintenance procedures!

Replacement of

Worn Shafts and Sheaths

Shafts and sheaths last longer when they are not

used at sharp angles or loops, since wear occurs

at the points of greatest friction. There is no way

to avoid ultimate wear, and under normal condi-

tions a flexible shaft machine may require several

replacement shafts and sheaths during its lifetime.

To expose the inner shaft follow steps 1, 2, and 3

on the previous page.

Next, remove motor

connector with 1

″

open end or

adjustable wrench.

Motor connector

has a left hand

thread and must

be turned clockwise (right) for removal.

Loosen set screw on the flexible shaft motor

coupling and slide shaft off the motor shaft.

Installation of New Shaft

1. After removing old shaft, loosen set screw on

the new flexible shaft motor coupling and slide

coupling onto motor shaft.

2. Tighten set

screw securely

onto the flat of the

motor shaft.

3. Grease shaft prior

to putting on the

sheath. (See lubrica-

tion instructions on

page 13.)

4. Slide motor

connector back up

over the shaft and

tighten to the left

(counterclockwise).

5. Slide sheath over flexible shaft with plain

fitting directed toward the motor and into the

motor connector. (Each end of the sheath has a

metal fitting. One is plain, the other has a groove

around it to fit the handpiece.)

6. Adjust the shaft (page 5 and top right) and

tighten sheath set screw in motor connector.

motor

coupling

motor

shaft

set screw

Visit

www.foredom.net

How-To Videos on Foredom flex shaft

set-up, maintenance and operation!

IMPORTANT!