Handpiece lubrication, Visit – Foredom Series SR User Manual

Page 10

10

To minimize repetition, we sometimes drop prefixes associated with Foredom part numbers.

Officially, Motors begin with M. (M.SR), Handpieces with H. (H.30

®

), and Speed Controls with C. (C.FCT).

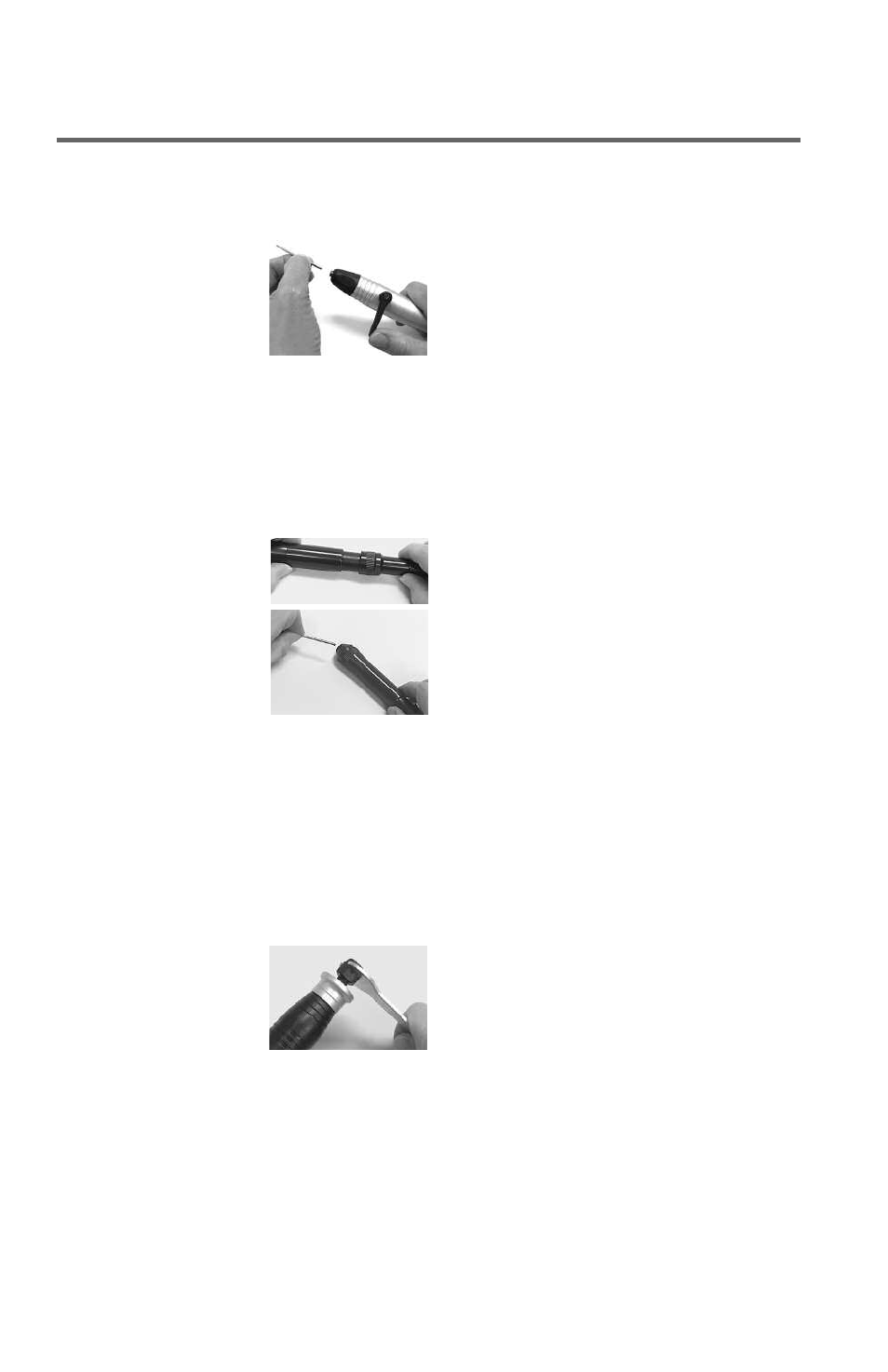

Attaching Accessories to Handpieces

Quick Change Type

— continued

20, 20D, 20SJ Handpiece:

This handpiece has a lever

action collet release mech-

anism. Wait for the motor,

flexible shaft, and accesso-

ry to come to a complete

stop before turning the lever to open the collet

and remove or insert accessory (2.35mm or

3/32

″ only). Turn lever 90˚ to left or right to open

collet and change an accessory. To close the col-

let turn the lever back to the position parallel to

the handpiece.

52, 52D, and 52SJ

Handpieces:

These quick change hand-

pieces have a unique

push/pull collet release

mechanism for rapid

accessory changing

(2.35mm or 3/32

″ only).

Wait for the motor, flexible shaft, and accessory

to come to a full stop before opening the collet.

After accessory has stopped rotating, pull the

top grip forward with one hand while holding the

bottom of the handpiece with the other. Remove

the accessory and insert the shank of the new

one fully into the collet. Push the top and bottom

portions together.

Chisel Type

—

50 and 50C Handpieces

(50C includes set of

six chisels):

Inserting a chisel into this reciprocating handpiece

should be done while the motor is in the “off”

position, or with the handpiece disconnected.

Loosen the locking nut with the 12mm spanner

wrench provided by unscrewing it counterclock-

wise. Insert the tang fully into the plunger shaft.

Tighten the locking nut clockwise until tool is

held securely. Do not over tighten.

Handpiece Lubrication

(See page 8 for handpiece photos.)

8, 18, 20, 25, (25H), 28, (28H),

30

®

, (30H) 35, 43T, 44T, (44HT) and 52:

These handpieces have been permanently

lubricated. Their greased-shielded ball bearings

should absolutely not be lubricated. (Handpieces

listed in brackets are for use with Series TXH

and LXH models only.)

10 and 10D: Lubrication should not be

required for the first 2–3 months of continuous

use. Then, approximately every two weeks of

use, lubrication of the front and back ends of

the handpiece is required. Follow the detailed

instructions that come with your handpiece.

8D, 10D, 15D, 18D, 20D, and 52D

Handpieces with Duplex Spring Connections:

Approximately every 20 hours of operation

apply 1 or 2 drops of Foredom oil (Part No.

MS10005) into the hole in the duplex spring

collar next to the sheath connector. This will

provide sufficient lubrication for both the

duplex spring connection and the

handpiece spindle.

15 and 15D: Clean off any dirt to prevent for-

eign matter from falling inside the handpiece.

Put two drops of Foredom oil into the oil hole

in the side of the housing. Run the handpiece

slowly to distribute the oil. Lubricate every

100 hours of use.

50 and 50C: After every 200 hours of use you

should clean and lubricate this handpiece. The

old grease must be cleaned off of the interior

cam chamber and replaced with new lubricant

(Part No. MS10008). Follow the detailed

instructions that come with your

chisel handpiece.

Visit

www.foredom.net

How-To Videos on Foredom flex shaft

set-up, maintenance and operation!