IAI America LSA-L15SS User Manual

Page 40

2. Installation

34

The surface to mount the main unit should be a machined surface or a plane that possesses an

equivalent accuracy and the flatness should be within 0.05mm/m.

The side surfaces and bottom surface of the base of the body have good parallelism to the guide.

Utilize these surfaces when accuracy in the actuator drive is required.

٧

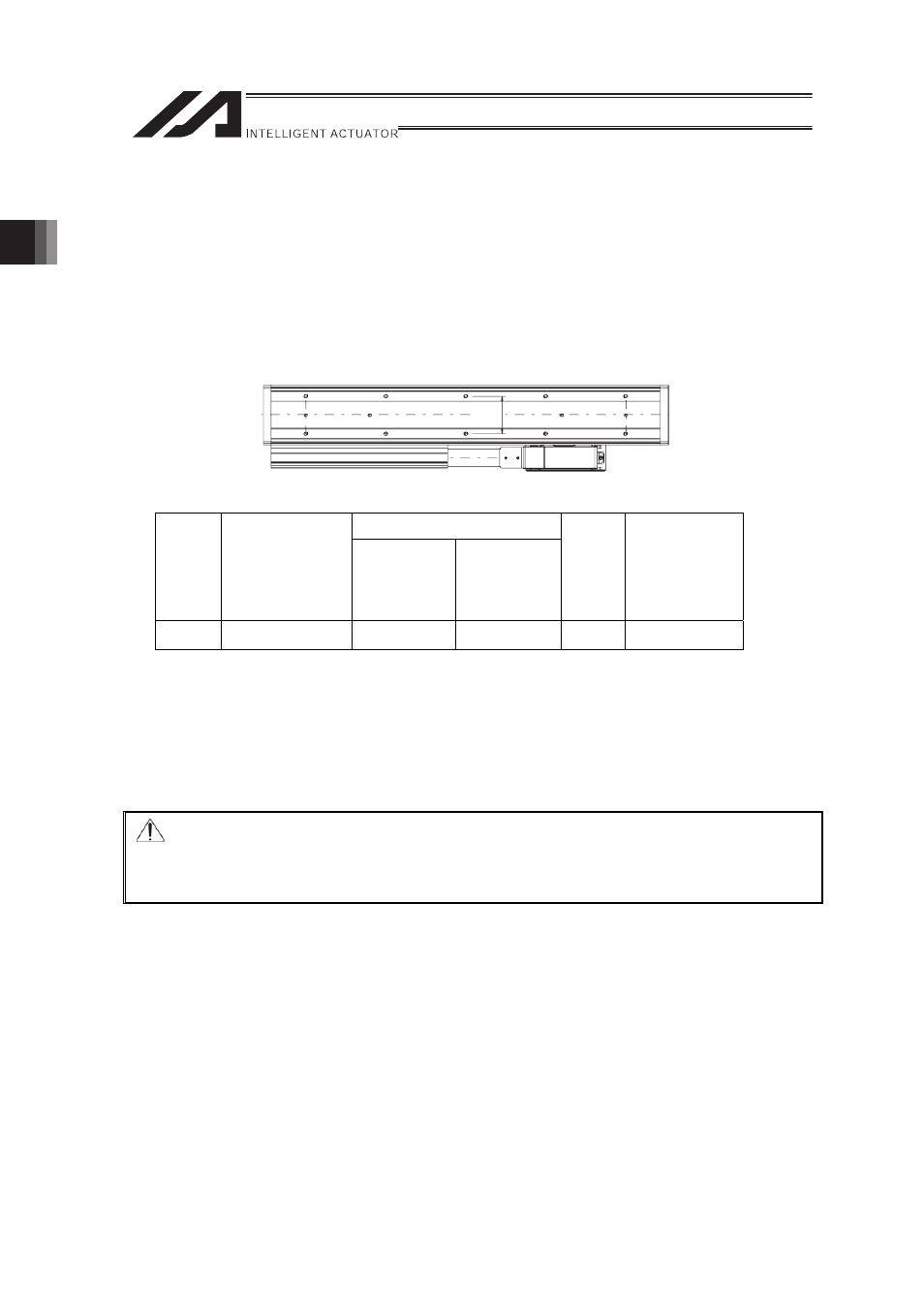

Small Type H8SS, H8SM, H8HS, H8HM

This actuator base has tapped mounting holes that can be used to affix the actuator from its back

(take note that the tap size is different depending on the model: Refer to the figure below and “8.

External Dimensions”.)

There are also reamed holes for accepting positioning pins.

50

Tightening Torque

Tapped

Hole

Size

Tapped Holes

Depth

In the case

that steel is

used for the

bolt seating

surface:

In the case

that aluminum

is used for the

bolt seating

surface:

Pitch

[mm]

Reamed Hole

[mm]

M5

5mm or more

10mm or less

7.27N·m

(0.74kgf·m)

3.42N·m

(0.35kgf·m)

50

I

4H7, depth 5

About Tightening Screws

• Use a hex socket head cap bolt for the attachment to the base.

• It is recommended to use high-tensile bolts with ISO-10.9 or more.

• Make sure to have the effective length of bolt engagement described below or more for the

tightening of a bolt and a female screw.

When female screw is on steel ĺ Thread length same as nominal diameter

When female screw is on aluminum ĺ Thread length 1.8 times longer them nominal diameter

Caution: Pay special attention when selecting the bolt length. In case that an inappropriate

length of a bolt is applied, it may cause damage on the tapped holes or insufficiency

in attachment strength, which may result in a drop in the operation accuracy or an

unexpected accident.