Maintenance inspection, 1 inspection items and inspection schedule, 2 visual inspection – IAI America RCS2-GR8 User Manual

Page 38: 3 cleaning, 5� maintenance inspection

5. Maintenance Inspection

32

5� Maintenance Inspection

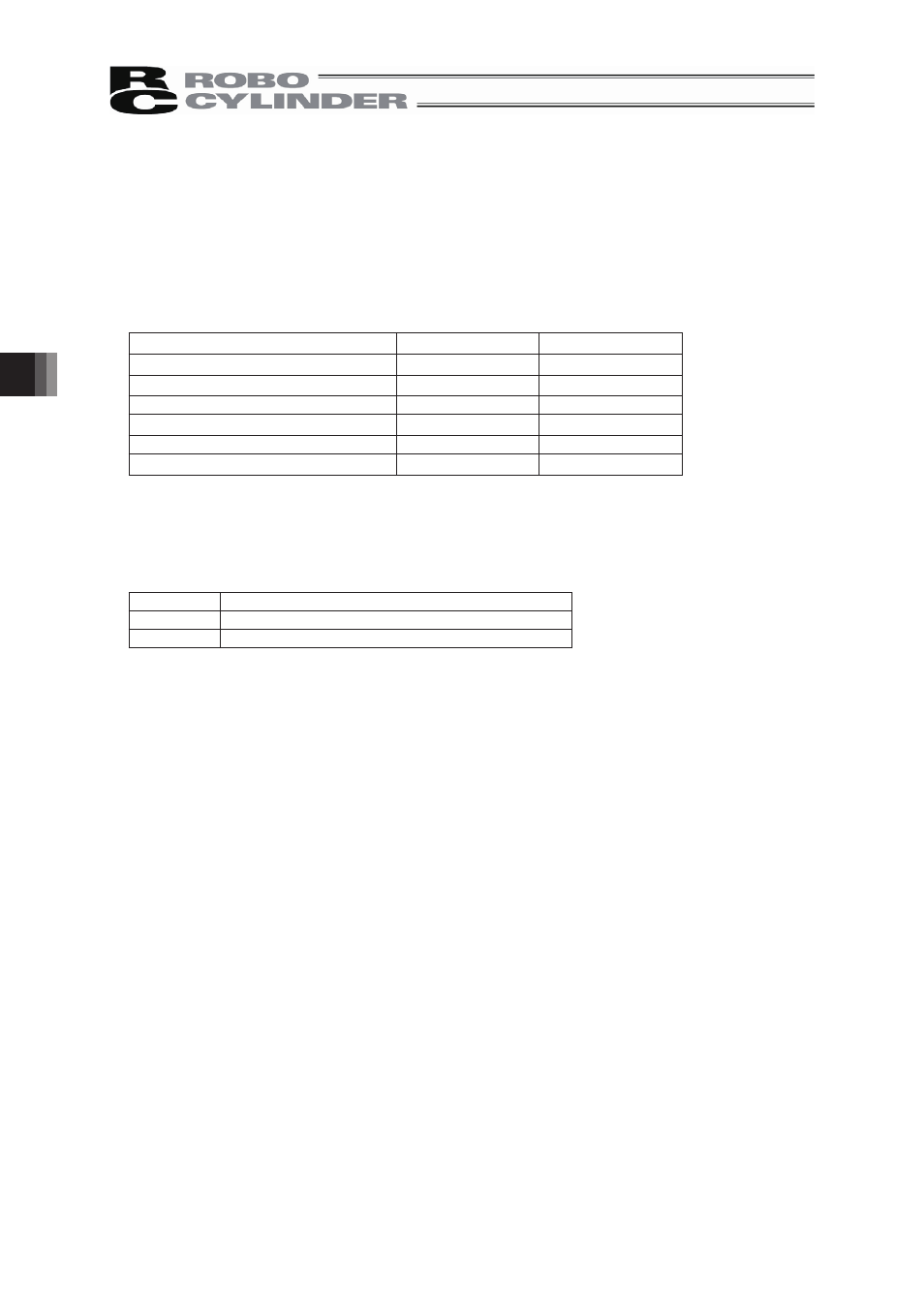

5.1 Inspection Items and Inspection Schedule

Have maintenance inspections following the intervals below.

The calculation is conducted under the condition that there are 8 working hours per day. Have

inspections more frequently if the operation frequency is high for night and day continuous operation,

etc.

�

Visual inspection

Grease supply

At startup inspection

��

�

1 month after start of operation

��

�

6 months after start of operation

��

��

1 year after start of operation

��

�

Every 6 months thereafter

��

��

Every year thereafter

��

�

5.2 Visual Inspection

For the visual inspection, check the appearance following items.

Actuator

Loosening of actuator mounting bolts, etc.

Cables

Scratches, proper connection of connectors

Overall

Noise, vibration

5.3 Cleaning

• Please clean the external body on a regular basis.

• When cleaning, wipe with a soft cloth to remove dust and dirt.

• There is a risk of dust getting in from a clearance. Do not blow compressed air strongly to the body.

• Do not apply petroleum solvent since it may damage the resin or painted surfaces.

• When extremely dirty, wipe it off firmly with cloth that a neutral detergent or alcohol is applied on.