Tools – Securitron LMD-1 User Manual

Page 2

PN#

500-18400

Page

2

Rev. C, 2/09

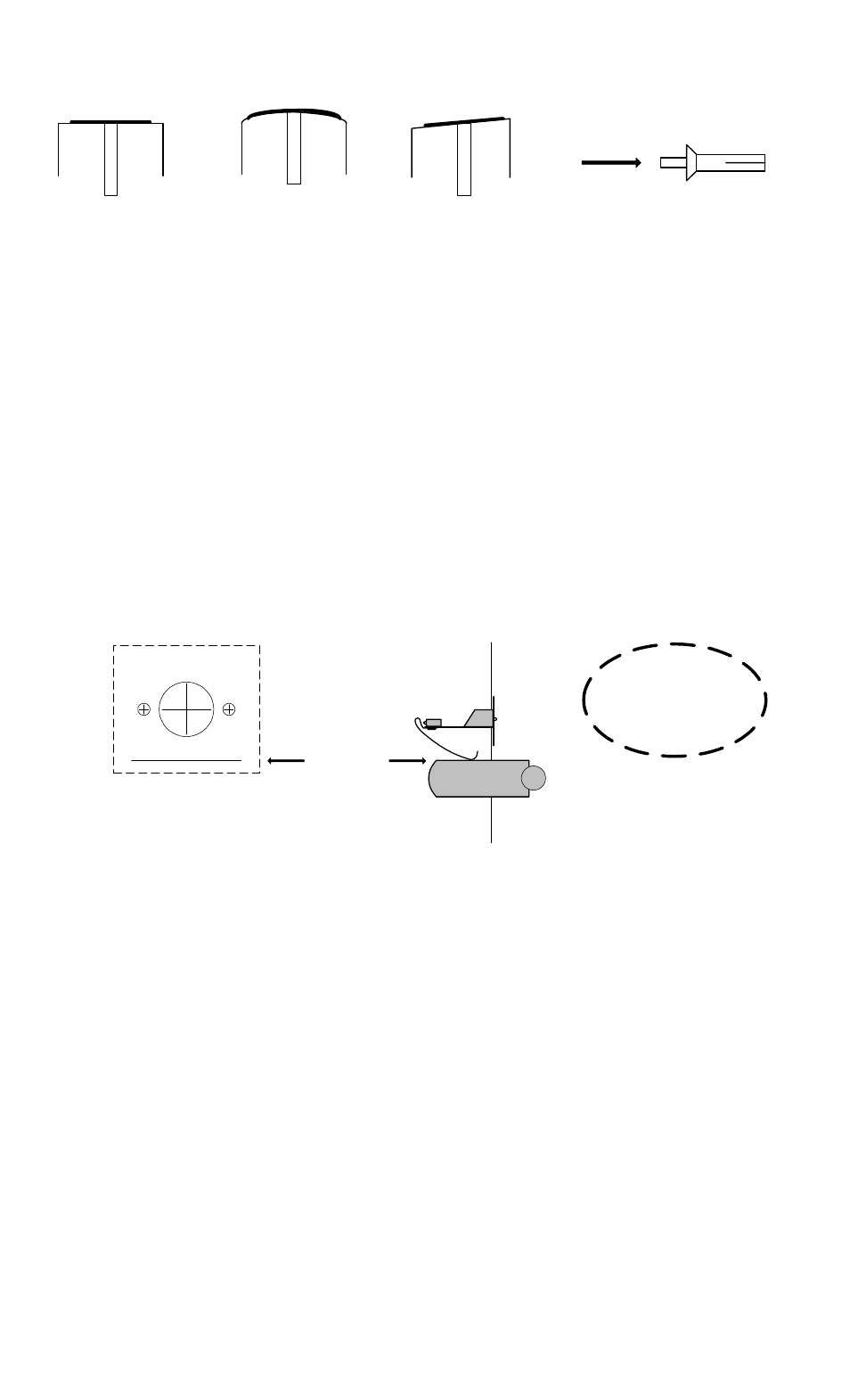

FIG. 2: MOUNTING IN FLAT, CURVED OR ANGLED FRAMES AND USE OF DRIVE RIVETS

FOR FLAT FRAME FACE (LEFT), UNIT INSTALLS NORMALLY.

FOR CURVED FRAME FACE (CENTER), THE MOUNTING PLATE

WILL BEND TO FOLLOW THE CURVE. FOR ANGLED FRAME

FACE (RIGHT) BEND THE PROJECTING BRACKET SLIGHTLY AS

SHOWN SO THAT IT FITS INTO THE CENTER OF THE FRAME

STILE

USE OF DRIVE RIVETS

INSERT LARGE END OF RIVET

THROUGH LMD MOUNTING

PLATE INTO HOLE IN FRAME.

TAP WITH HAMMER FROM THE

DIRECTION SHOWN BY THE

ARROW TO SEAT THE RIVET.

3. OPERATION

Finally note that tampering or mechanical failure of the unit is possible. For best system

reliability therefore, the unit should be periodically tested to confirm that the output changes

state as the Deadlock seats and is opened.

4. WIRING

The Deadlock Monitor has three wires (SPDT, form C) that are assigned by color as follows:

White = Common

Red = N.C.

Blue = N.O.

Because we’re using the terms normally open and normally closed, it’s necessary to define what

we mean by “normal”. The normal condition of the Deadlock Monitor is when it is

reporting secure (the door is locked). So, for example, you’ll read a closed circuit between

White and Red if you meter the unit in the secure condition but you’ll read open if you meter it

in the alarm condition (door is open). Maximum contact ratings are 2 Amps at 24V.

LINE IS EVEN WITH TOP OF BOLT

9/16" DIA

1/8" DIA

1/8" DIA

TEMPLATE

CENTER HOLES ON FRAME

CUT OUT TEMPLATE ON

DOTTED LINE

ALIGNMENT

TOOLS:

1/2" DRIVE DRILL

1/8" (3MM) BIT

9/16" (15MM) BIT

HAMMER