Reese 38208 CLASS V SUPER TITAN User Manual

Installation instructions, Bolt-on 25k super titan, Part numbers

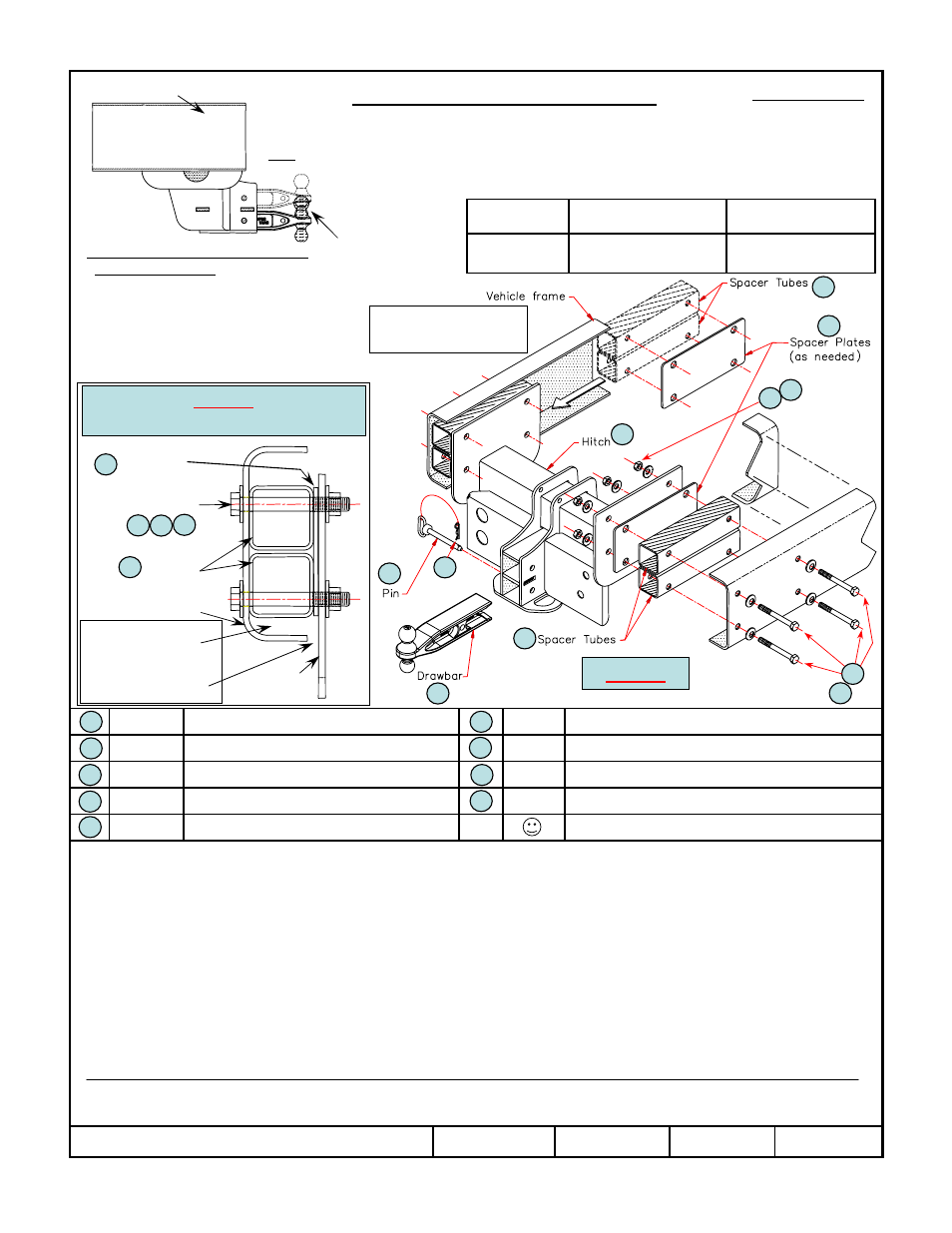

Installation Instructions

Bolt-on 25K Super Titan

Designed for “C” channel style frames approximately 34”-34 ½” wide.

Note; this hitch is heavy and will require more than one person, a lifting device or both.

Part Numbers:

38208

Hitch Shown In Proper Position

Equipment Required:

Wrenches: 1-1/8” wrench & sockets.

Rev. A

1-29-09

38208N

Sheet 1 of 3

z

2009 Cequent Performance Products

Note: check hitch frequently, making sure all fasteners are properly tightened. Check condition of drawbar and pin before every time you tow. A hitch or ball which

has been damaged should be removed and replaced. Observe safety precautions when working beneath a vehicle and wear eye protection. Do not cut access or

attachment holes with a torch. This hitch was designed to be installed with the included hardware/components supplied. Observe all vehicle manufacturers guidelines.

Fastener Kit: 38208F

Do Not Exceed Lower of Towing Vehicle Manufacturer’s Rating or

Form: F205 Rev A 5-6-05

Tighten all 3/4”-16 Grade 8 fasteners with torque wrench to 325 Lb. -Ft. (440 N*M)

Pin Clip

Qty. (1)

3/4”-16 X 6” Gr. 8 hex hd. Bolt

Qty. (8)

Drawbar Pin with lanyard

Qty. (1)

Spacer Plates, (use as needed)

Qty. (2)

Drawbar

Qty. (1)

Spacer Tube

Qty. (4)

Another fine Cequent Performance Products Hitch

3/4” Conical toothed Washer

Qty. (16)

3/4” Gr. 5 hex Nut

Qty. (8)

Hitch

Qty. (1)

1.

Determine if width and height of vehicle frame is adequate for this hitch. Measure inside surfaces of “C” channel vehicle frame width and

height and compare that to overall outside hitch with spacer tubes width and height. Keep in mind that supplied hitch spacer plates can be

removed to achieve minimum width.

2.

Determine location of hitch within frame before drilling holes. Keep in mind installed drawbar to check vehicle, trailer and ground

clearances. After determining that hitch location is adequate then layout holes on outside of vehicle frame, see

Figure A.

above. Carefully

match hole spacing of layout holes on frame to dimensions between holes on hitch brackets. Center punch location of holes on vehicle frame

so that they are drilled accurately.

3.

Drill all center-punched locations using 1/4” drill bit. Then proceed with 1/2” bit and then finally 25/32”. Remove any burrs from around

drilled holes. As shown in

Figure B.

above insert bolts with washers from outside of frame into place. Install spacer tubes over bolts as

shown. If spacer plates are needed then install these over bolts against tubes. Pull all bolts back slightly so that you can raise hitch into

position and then push bolts back through holes in hitch brackets as shown in

Figure B.

4.

Install washers and nuts onto bolts and then holding hitch up level torque all fasteners to specifications below.

Vehicle frame

4000 Lb. (1814.4 Kg)

25,000 Lb. (11340 Kg)

Weight Carrying

Ball Mount

Max Tongue

Weight

Max Gross

Trailer Weight

Hitch type

1

2

6

Figure A.

Rear view of Frame showing proper installation

4

3

1

2

Figure B.

7

Other Tools: Tape Measure, Layout tools,

Center Punch, Hammer, small & large Drill Motor,

Torque Wrench capable of 325 ft-lb., (440 N*M)

All fasteners typical,

both sides of vehicle.

Drill bits: 1/4”, 1/2”, 25/32”

3

4

5

8

9

Vehicle frame

Supplied

Spacer Tubes

Supplied Spacer Plate

(if needed)

Hitch

Bracket

Supplied Bolt, Washers,

Nut, typical

2

3

4

5

6

Spacer Tube not

designed to rest on

bottom frame flange.

Hitch bracket not

designed to clamp frame.

2

5

6

5 Typical

7

8

9

Drawbar either top or

bottom opening.

Turn over for 2” Ball