Ransburg, Troubleshooting guide (cont.), Fluid system electrical – Ransburg Evolver Solvent Robot Applicator 79190-XXXXXXXX User Manual

Page 54

Note: To check for fluid leaks, it is easiest to first remove the gun from the test station and remove

the shroud from the gun. Then the gun can be remounted to the test station. Leak detector may be

used at all appropriate sources. Be certain to wipe off all residual solution using a non-conductive

solvent such

as Naphtha.

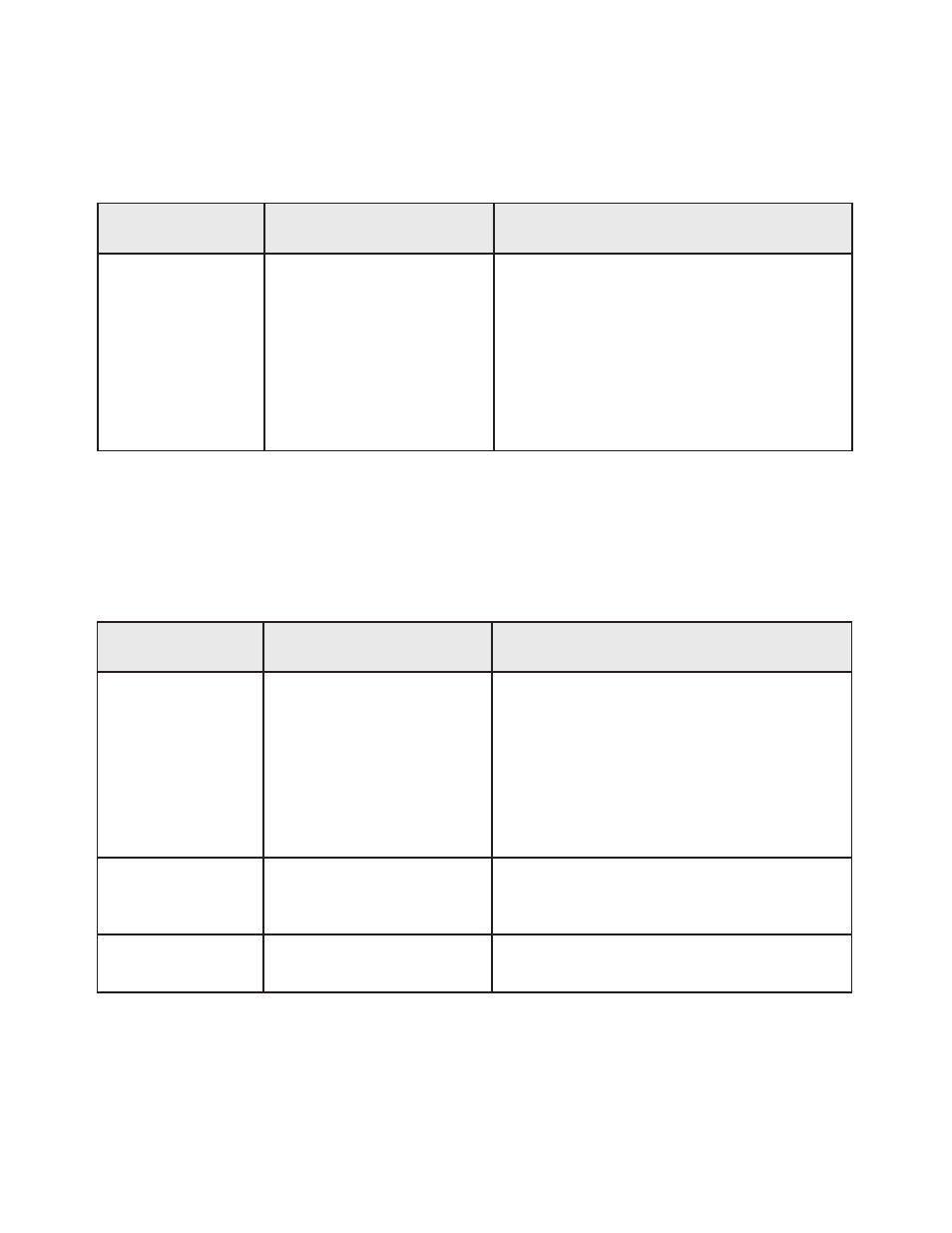

TROUBLESHOOTING GUIDE (Cont.)

General Problem

Possible Causes

Corrective Action

Excessive Current

or Loss of High

Voltage

1. Metallic particle alignment

in coiled tube

2. Fluid leaks inside

3. Fluid coil pin-holed

4. Exterior of gun contami-

nated

1. Start fluid flow before turning voltage on.

2. Repair/replace fittings and/or coiled fluid tube

as required.

3. Replace coil as required.

4. Clean with non-polar solvent.

Fluid System

Electrical

General Problem

Possible Causes

Corrective Action

No Electrostatics

Low kV, High µA

Output

Low kV, Low µA

Output

1. Cascade not functioning

1. Exterior of gun contaminat-

ed with conductive material

1. Cascade failure

1. Check low voltage cable and harness timing

mark positions. Correct as required.

2. Cascade bad. Replace as required.

3. Low voltage cable connections wrong at

MicroPak.

4. Low voltage cable bad. Replace as required.

1. Replace gun cover.

2. Clean exterior with a non-polar solvent.

1. Replace as required.

Evolver Solventborne Robotic Atomizers - Maintenance

50

Ransburg

AA-03-02.12