Ransburg, Current output test, Polar and non-polar solvents – Ransburg Evolver Solvent Robot Applicator 79190-XXXXXXXX User Manual

Page 31

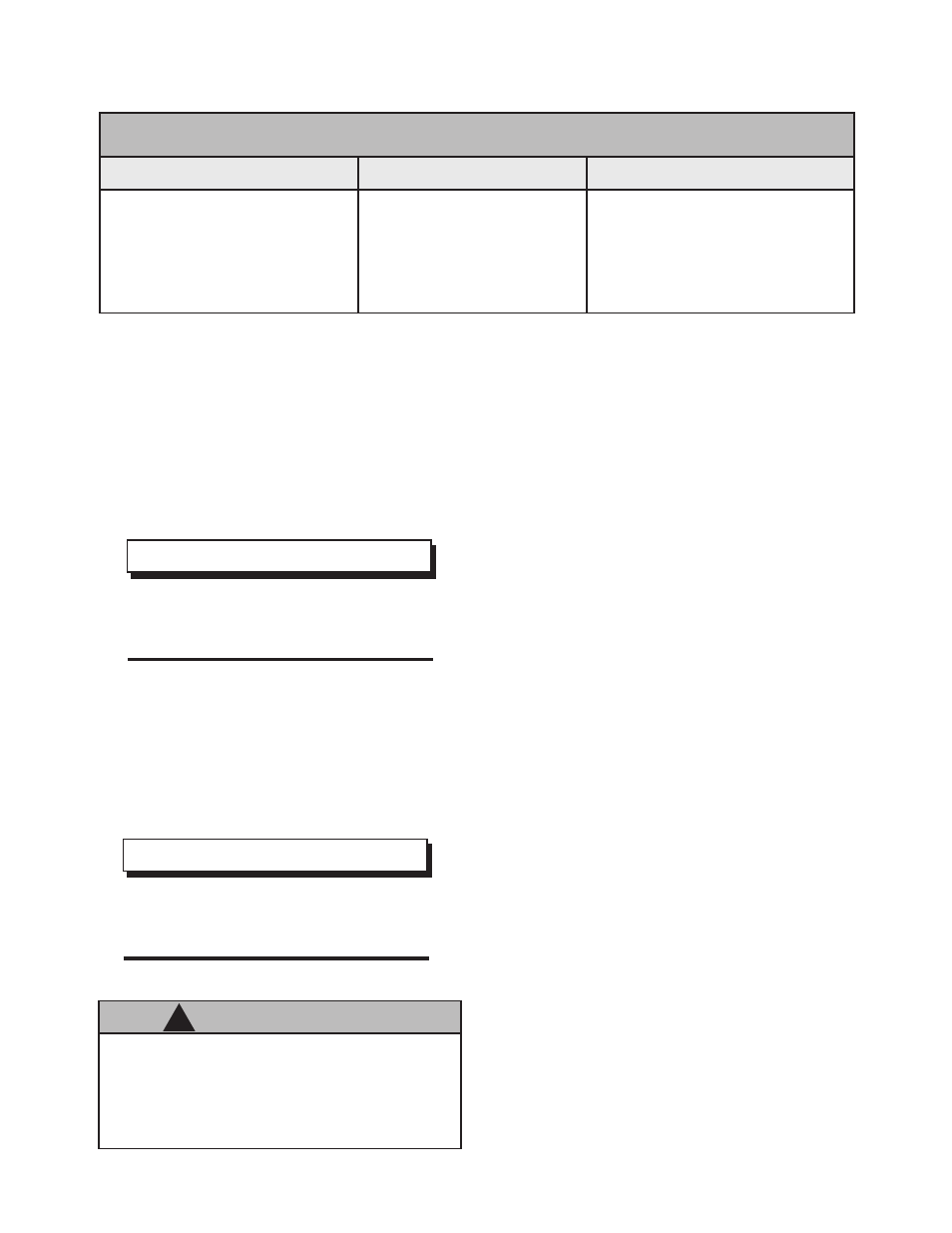

Figure 7: Polar and Non-Polar Solvents

8. Remove fluid nozzle [32] by unscrewing count-

er-clockwise. Inspect o-ring [30] and all passages

for build up or damage. Clean or replace as neces-

sary. Lubricate and reinsert o-ring into gun barrel

and reinstall fluid nozzle. Torque fluid nozzle to

25 lbs•in (2.82 Nm).

>

There should be a small gap between

the fluid nozzle and the gun barrel after

tightening.

NOTE

9. After cleaning, insert the electrode assembly

[31] back into the spray head assembly. Apply

adhesive #222, low strength (purple) thread-lock-

er, to the threads of the electrode assembly before

reassembly.

10. Screw fluid tip [34] back into place. Hand

tighten first, then with a small wrench, tighten an

additional 30 degrees.

11. Replace air cap locator [33], air cap [35], and

air cap retainer [36].

12. Apply a thin film of petroleum jelly to valve and

needle springs [2] and [3]. Install the springs back

into the end cap and the spray head assembly.

13. Screw end cap [1] back on.

Current Output Test

1. Clean and blow out all fluid passages with

non-conductive solvent.

2. Remove from robot and perform bench test

using a spare tubing bundle.

3. Turn the control unit power

ON.

4. Activate high voltage and slowly approach the

gun electrode with ground hook or wire.

5. Monitor the current output on the MicroPak.

Current should rise as ground approaches. At

approximately 85 microamperes, the MicroPak

will shut off. The

OVERCURRENT indicator

should come on.

The spray head can be removed from assembly

as shown in Figure 8 for cleaning and service.

>

The fluid tip [34] should always be

installed and tightened before installing

the needle and valve springs.

NOTE

>

After tightening the fluid tip, always check

to see if the proper gap (1/16") between the

needle nuts and air valve stem occur, before

installng the needle and valve springs back

into the head.

C A U T I O N

!

Amyl Acetate

Methyl Amyl Acetate

Toluene

Xylene

High Flash Naptha

Mineral Spirits

Non-Conductive (Non-Polar)

POLAR AND NON-POLAR SOLVENTS

Moderately Conductive

Extremely Conductive (Polar)

Methyl

Isobutyl Ketone

Ethyl Acetate

Methyl Ethyl Ketone

Butyl Carbitol

Methanol

Carbitol

Diacetone

Butyl Alcohol

Acetone

Butyl Cellosolve

Evolver Solventborne Robotic Atomizers - Maintenance

27

Ransburg

AA-03-02.12