Troubleshooting guide, Ransburg, Vector solo aa90 applicators - maintenance – Ransburg Vector Solo AA90 79698 User Manual

Page 45

Vector Solo AA90 Applicators - Maintenance

Ransburg

41

AH-08-04.2

(Continued On Next Page)

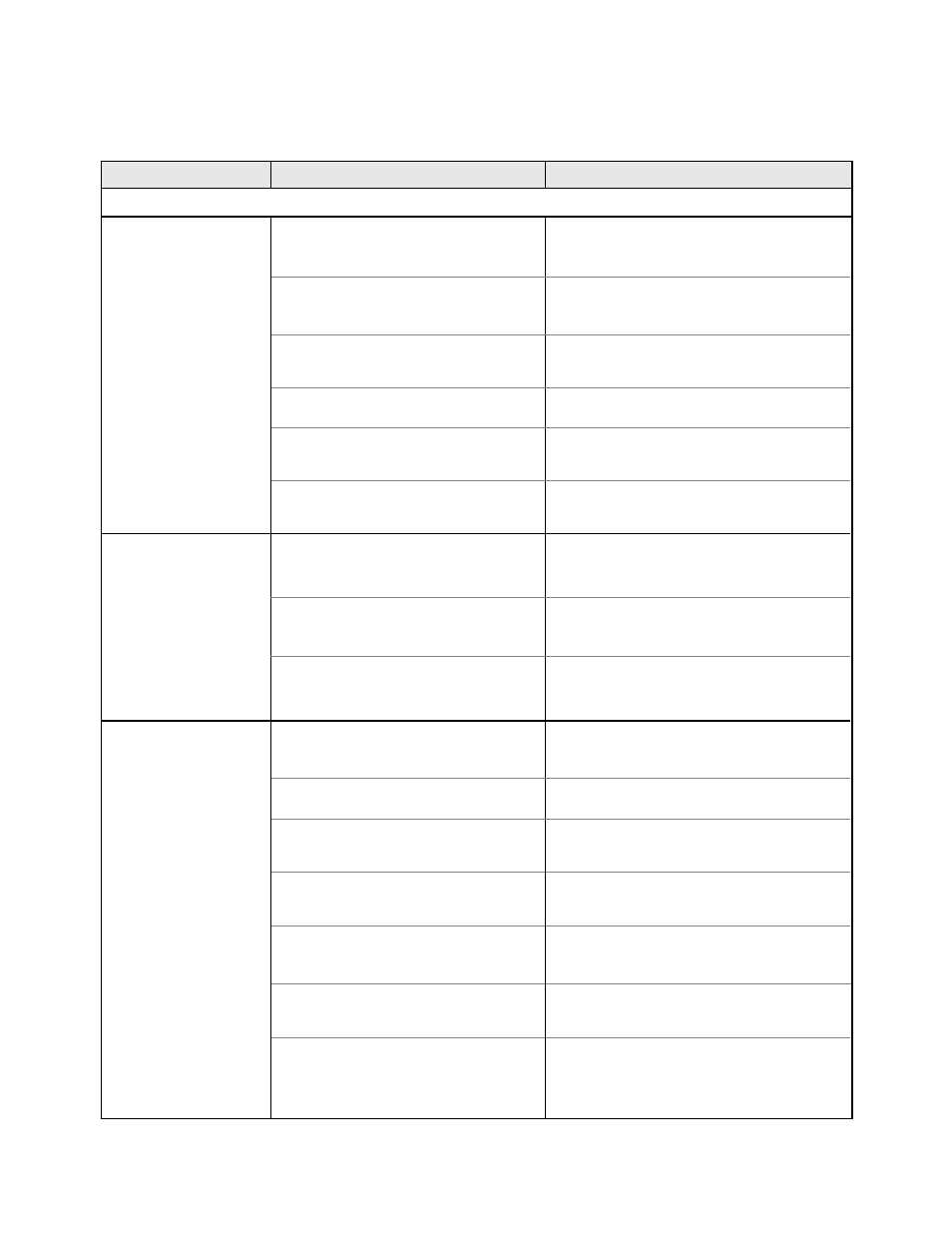

TROUBLESHOOTING GUIDE

General Problem

Possible Cause

Solution

ELECTRICAL

No kV

Low kV

Poor Atomization

and Distribution

On-Off lever in wrong position

Low pressure

No ground connection

Cascade not functioning

Three (3) screws at base of handle

are loose

Failed power module

Ensure the On/Off lever is in the

On position.

Ensure 40 psig (2.75 bar) at the applicator

handle with applicator triggered.

Ensure the air hose is properly grounded

to the earth ground.

Ensure cascade is functioning properly.

Tighten screws to ensure proper

assembly.

Ensure module is properly functioning.

Fluid remnants in the air passage

Wrong solvent used for final cleaning

process

Add sufficient air pressure at handle

Clean air passages with non-polar

solvent.

Use non-polar solvent for the final

cleaning process.

Ensure 2.8 bar (40 psig) at the handle

with applicator triggered.

Partially clogged nozzle

Low fluid pressure

Viscosity too high

Improper nozzle

Badly worn nozzle

High voltage electrode bend

Low shaping air pressure

Clean out.

Increase pump air pressure.

Try nozzle with narrower fan or smaller

orifice.

Try nozzle with narrower fan or smaller

orifice.

Thin the material to a viscosity that is

sprayable.

Straighten electrode or replace nozzle

assembly.

Re-adjust shaping air pressure.