Ransburg, Vector solo aa90 applicators - maintenance, Air hose -applicator end – Ransburg Vector Solo AA90 79698 User Manual

Page 44: Resistance test

Vector Solo AA90 Applicators - Maintenance

Ransburg

40

AH-08-04.2

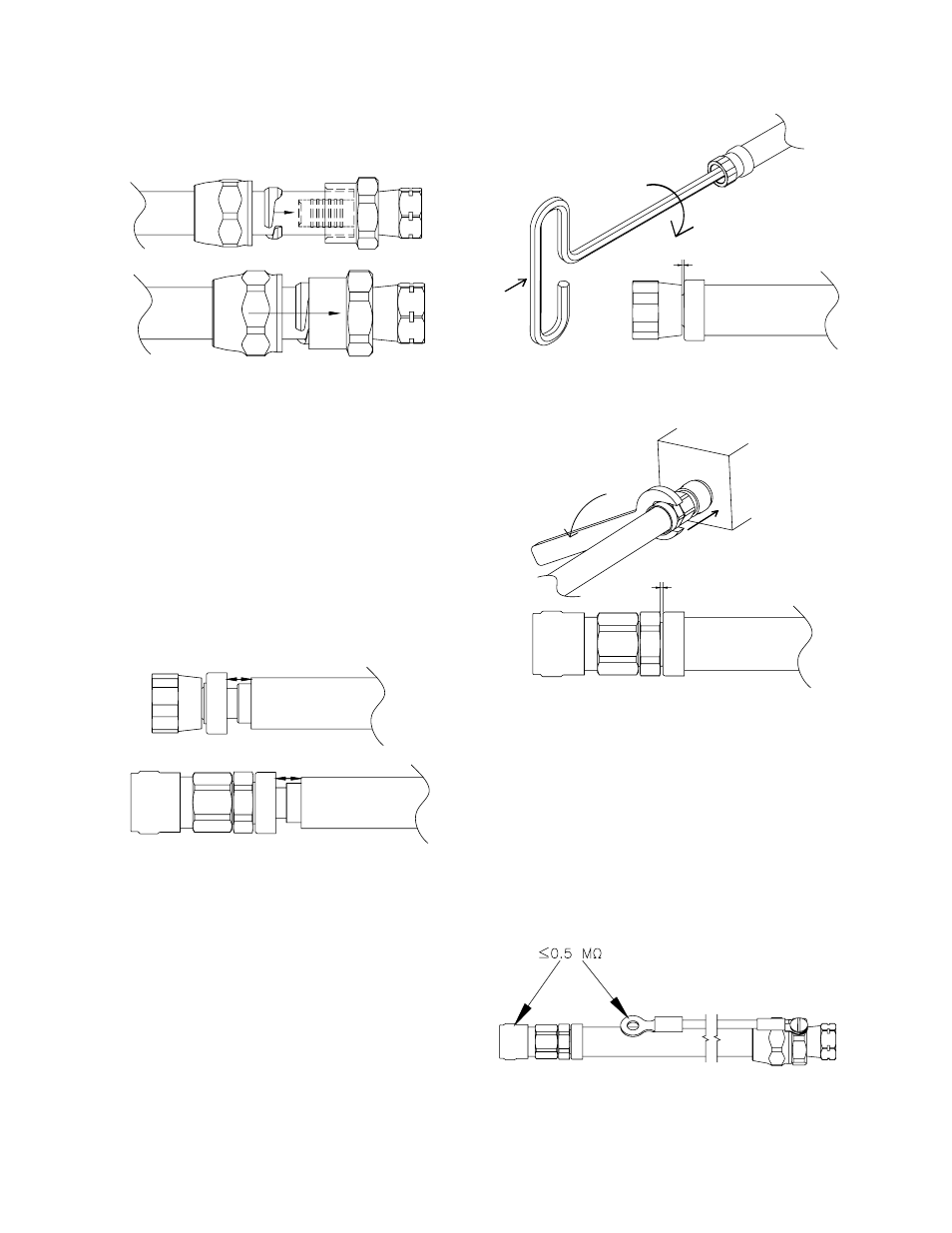

4. Slide the compression ring and the sleeve into

the fitting body and tighten.

Air Hose -Applicator End

1. Cut the end of the air hose so that end is square.

2. Install the 79930 fitting (std) or 79868 (qd)

into the hose end. Lightly lubricate the barb end

of the fitting with LSCH-0009 di-electric lubricant.

Push the fitting into the air hose up to the threads

on the stem.

3. With the 79330 fitting, hold the hose in one hand

and press a 6mm or 1/4" t-handle allen wrench

into the hex in the part while turning clockwise.

Tighten till cap is approximately .8 mm (1/32")

from the swivel nut.

Resistance Test

1. If the hose is changed, the resistance must

be checked. Using a Meg Ohm meter at 1000V

measure the resistance from the lug of the ground

wire to the body of the QD (79868) or the swivel

nut (79930). The reading must be less than .5

Mega Ohms resistance end to end.

Figure 75: Sleeve Tightening

Figure 76: Fitting Insertion

Figure 77: Tightening 79930 Fitting

4. With the 79868 DQ fitting, hold the hose in one

hand and press against a firm surface while turning

the body wrench flat clockwise. Tighten till cap is

approximately .8 mm (1/32") from the QD base.

Figure 78: Tightening 79868 QD Fitting

Figure 79: Air Hose Resistance Test

0.8mm (1/32")

0.8mm (1/32")