Flushing/color change procedure, Ransburg, Flushing / color change procedure – Ransburg Vector Solo AA90 79698 User Manual

Page 22: Vector solo aa90 applicators - operation

Vector Solo AA90 Applicators - Operation

Ransburg

18

AH-08-04.2

79692-01

79692-02

79692-03

79692-04

79692-06

79692-07

.1010" (.256mm)

.1021" (.307mm)

.0141" (.358mm)

.0161" (.409mm)

.0201" (.511mm)

.0221" (.561mm)

Part #

Restrictor Orifice Size

Matching Spray Tip Part #

79691-0509,-1009

79691-0511, -0811, -1011, -1311, -1511

79691-0513, -0813, -1013, -1313, -1513

79691-1015, -1315, -1515, -1715

79691-1018, -1318, -1518

79691-1021, -1521

TABLE II - 79692-XX PRE-ORIFICE SEAL SIZES

2. Turn off supply air.

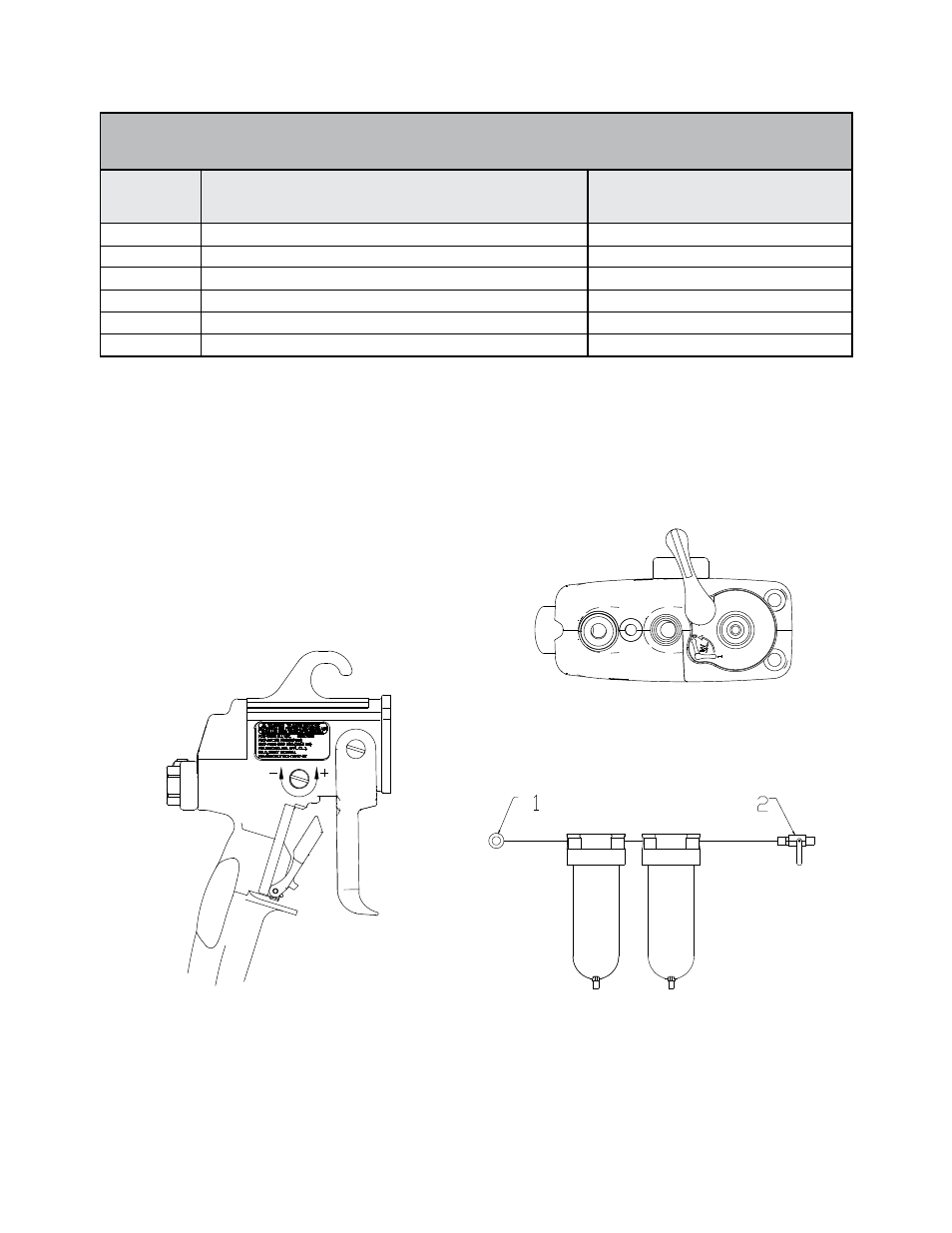

Figure 15: Applicator Supply Air - Off

Figure 14: Electrostatics Lever Off Position

FLUSHING / COLOR

CHANGE PROCEDURE

1. Turn electrostatic lever to Off position.

Figure 13: Compensation Valve - Full

Open Position

8. The applicator is shipped standard with a plug

in the atomization air port. If lower atomization

air pressures are desired, a compensation valve

is included with each applicator and can be used

instead of the plug. The compensation valve

(included seperate with applicator) reduces the

atomization air pressure approximately 0.2 bar

(3 psig) per clockwise turn from the wide open

position. To determine what pressure the applica-

tor is set at, use the Air Cap Test Kit in the "Parts

Identification - Accessories" section.

1 - Main Air Supply

2 - Closed Ball Valve