Ransburg, Vector solo aa90 applicators - maintenance, Needle shaft pack reassembly – Ransburg Vector Solo AA90 79698 User Manual

Page 36: Needle shaft rebuild, Reinstall needle shaft/barrel

Vector Solo AA90 Applicators - Maintenance

Ransburg

32

AH-08-04.2

3. Remove front spreader seal, front u-cup seal,

rear spreader seal, rear u-cup seal, and pusher

seal.

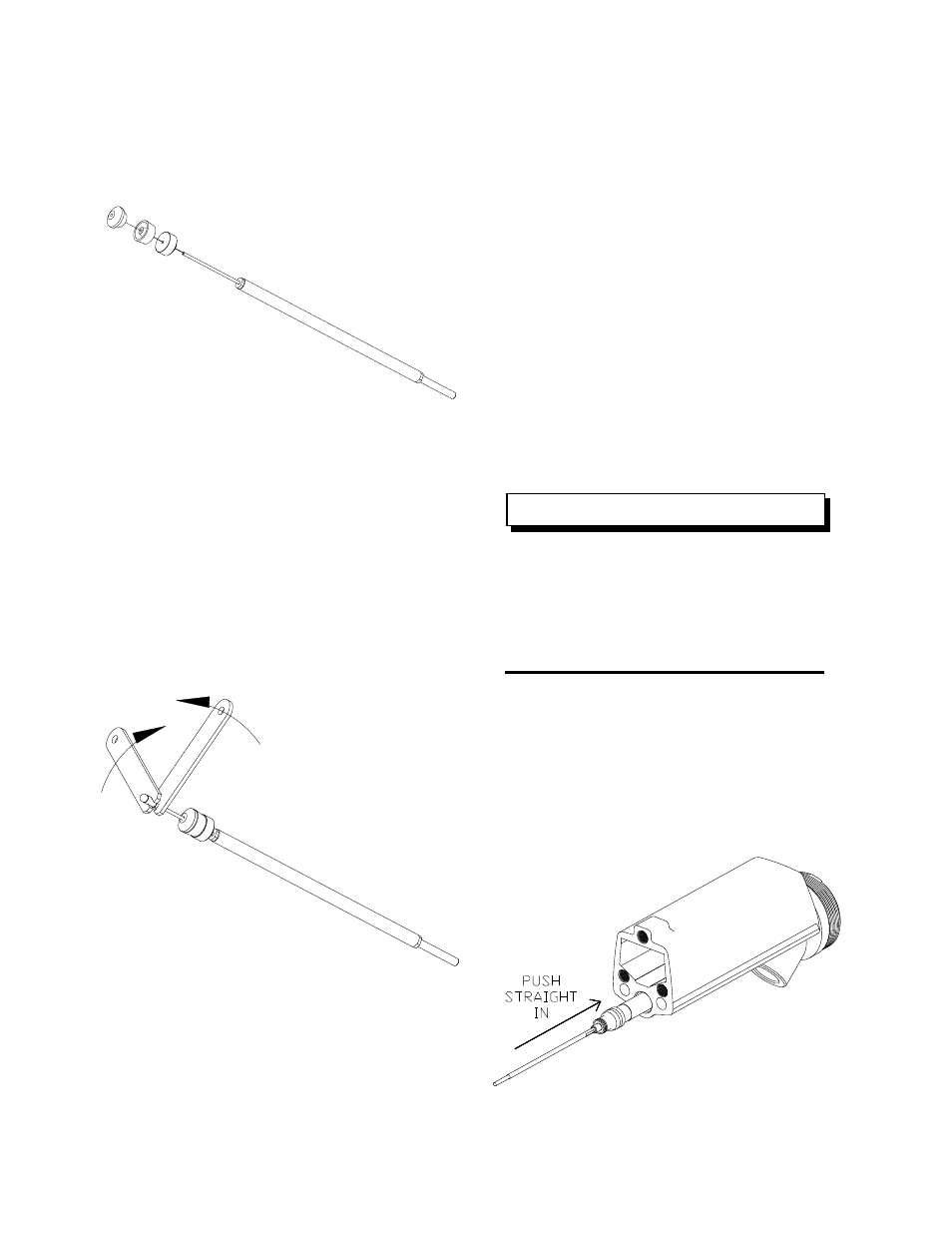

Figure 43: Needle Shaft Packing Replacement

Figure 44: Needle Shaft Packing Reassembly

Needle Shaft Pack Reassembly

1. Install pusher seal, rear u-cup, rear spreader

seal, front u-cup seal, front spreader seal as shown.

Orient seals per Figures 41 and 43.

2. Install jam nut all the way on the shaft. Install

the carbide ball all the way down using two 74133

tools. Tighten the jam nut against the carbide ball.

Needle Shaft Rebuild

1. Prior to installing the needle shaft, partially fill

the internal bore of barrel with dielectric grease.

2. Fill the inner diameter of the packing tube with

dielectric grease.

3. Insert the needle shaft, rear section first, into

the packing tube. Rotate the needle shaft while

moving back and forth inside the packing tube

until fully inserted.

4. With your finger, wipe the excess grease from

both ends of the packing tube. Using the excess

grease, apply a thin film to the outer surface of

the packing tube and to the external o-ring on the

cartridge seal.

5. Apply a light film of dielectric grease to the seal

retainer o-ring and install it into the external groove.

Reinstall Needle Shaft/Barrel

1. Push needle shaft assembly straight into the

barrel. Apply LSCH0009-00.

Be generous with the dielectric grease

when applying it to the packing tube and

needle shaft. This helps to remove air

voids from this chamber.

DO NOT apply

so much grease that it creates an air lock

during assembly of the applicator.

NOTE

Figure 45: Needle Shaft Replacement